www.hi-velocity.com

© 1995-2017 Energy Saving Products Ltd.

After all of the Branch Take-Offs have been installed, the

flexible duct can then be fastened to the joist with strapping

material. Staples may be used, as long as the insulation sleeve

isn’t damaged or torn.

Only use staples if local code allows.

If the insulation

sleeve is damaged use foil duct tape to seal the sleeve, do not use

cloth style tapes as they will not create a proper seal. Try to run

the flexible duct parallel to the joists whenever possible as this

takes less space (Fig. DUC-14).

Fig. DUC-14 - Use strapping to hold the Flexible duct

Fig. DUC-15 - Through or under joists

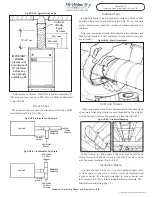

When larger holes (4”/102mm) can be drilled, then the

insulated flex duct may be pulled through whole. If code or the

designer only allow for a 2 3/8” (60mm) or 3” (76mm) hole, the

insulation must first be removed from the flexible duct (Fig. DUC-

16a). The insulation is then cut into lengths that correspond to

the joist spacing. As the inner soft core of the flexible duct is fed

into each hole the insulation is slid over the core (Fig. DUC-16b).

Fig. DUC-16a - 2 3/8” holes (60mm)

Fig. DUC-16b - Add insulation at each joist

When installing the flexible duct in areas in which you must

run opposite to the direction of solid joists, some drilling may be

required. It is recommended to drill the smallest hole possible

(Fig. DUC-15) in order to maintain structural integrity. Check

with local code laws and ensure that it is allowable to drill holes

through the joists before proceeding. If possible, run the flex

duct under the joists and avoid drilling any holes.

The flexible duct should never be cut shorter than 10’ (3.05m)

in length. If the run to the outlet is less than 10’ (3.05m) the

flexible duct can be coiled up. The bends in the flexible duct

shall have a minimum radius of 6” or 152mm (7” or 178mm for

HE Duct) (Fig. DUC-17). Sharp bends in the flexible duct will

reduce airflow to that vent. Also note that runs that are perfectly

straight, or stretched out too far, can also have a higher noise

volume than usual.

Fig. DUC-17 - 6” (152mm) minimum radius on bends

If a T-Bar ceiling is going to be installed, it is far easier to

run the flexible duct in that space, rather than drilling through

several joists.

Module DUC

Installing Plenum and Branch Duct (5/9)

Module DUC Installing Plenum and Branch Duct (5/9)

Flexible Duct Placement

-14-

MIN.

6” or

152mm

BEND

RADIUS (7”

or 178mm

for HE)