15

Preparing for an Alignment

There are several preparations that need to be made before beginning a measurement or alignment process. Ensure that

accurate records are kept for all procedures.

Cleaning the Plate

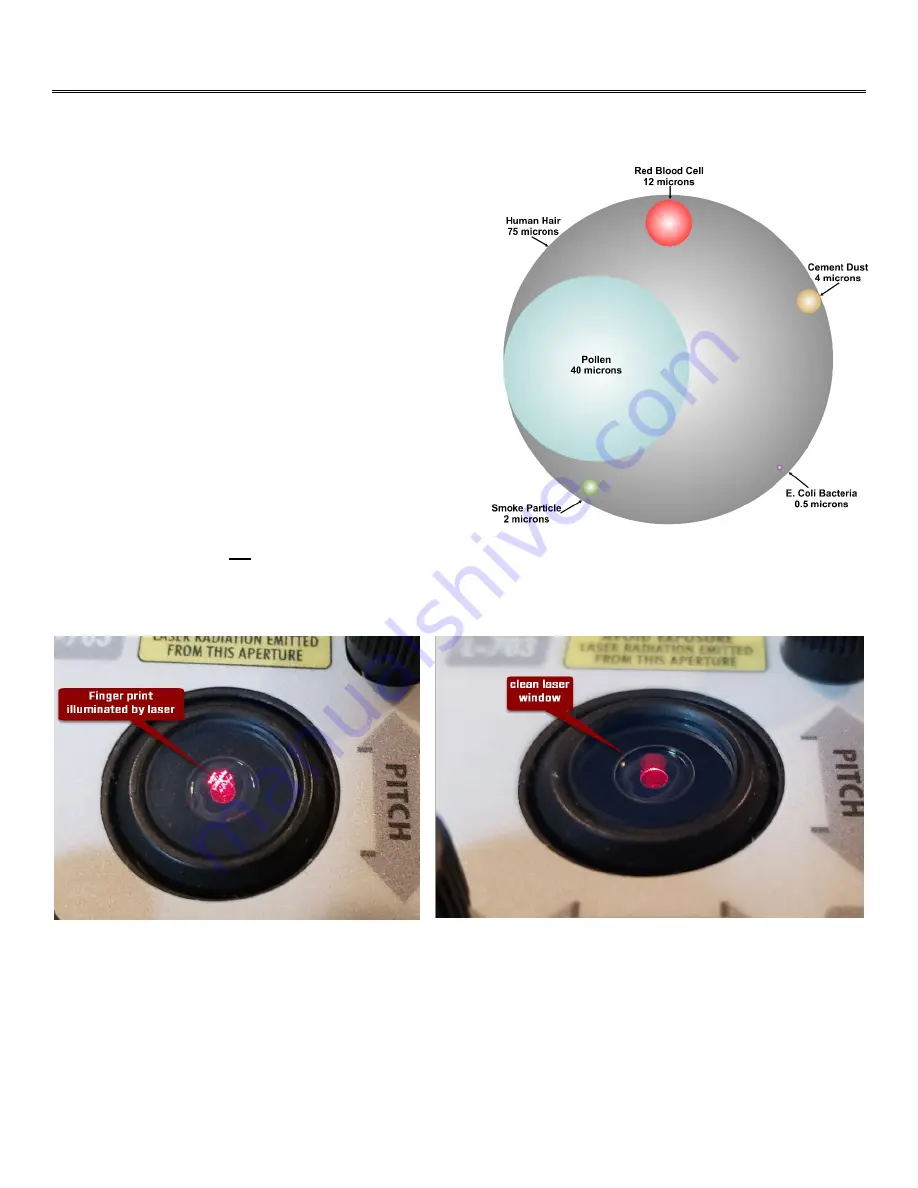

For accurate calibration results is highly important to clean

the surface plate prior to starting the calibration check. Use

approved surfaced plate cleaners and cloths to remove all dust

and dirt (see

Relative Particle Sizes). If you are

trying to calibrate a 36x36 in. plate to a Grade A spec, the

flatness requirement is 300 µin. or 8 µm (microns). As you

can see a few grains of dust (4 microns) on your plate and this

eats up half of the Grade A tolerance and can significantly

impact the flatness data! Run your hand over the plate to feel

for dust and make sure it’s ready to check the flatness.

Maintenance and Cleaning of L-703SP & T-1297

The windows on the T-1297 target should be clean and free

from dirt, thumbprints and other smudges. Clean the window

with alcohol wipes or a Q-tip soaked in alcohol. Always wipe

in the same direction. Do

not

wipe back and forth.

The same applies to the L-703SP Laser Window. If you see a reflection on the lens window on the laser (

19),

this means it is contaminated and needs to be cleaned.

Figure 19 - Dirty vs. Clean Laser Window Example

Target Calibration

The T-1297 Targets are calibrated and the calibration factors are stored inside the target, so there is no need to upload

calibration factors into Plane6.

Figure 18 - Relative Particles Sizes

Содержание L-703SP

Страница 1: ......

Страница 54: ...50 An example on how to do the Math to get the exact flatness values...

Страница 55: ...51 Plane6 Sample Report...