Model T1243 (Mfd. Since 02/18)

-17-

SECTION 5: MAINTENANCE

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Schedule

For optimum performance from your cross-slide

rotary table, follow this maintenance schedule

and refer to any specific instructions given in this

section.

Daily/Before Use:

•

Clean and lubricate the ball oilers.

•

Dress the machined surfaces.

•

Check/resolve any unsafe condition.

Monthly:

•

Clean and lubricate X- and Y-axis

leadscrews.

Cleaning &

Protecting

It is essential that the rotary table be cleaned

after every use, and the surfaces oiled with a light

machine oil to prevent corrosion.

DO NOT use compressed air to clean your

rotary table. Chips or debris may become lodged

between the moving parts, reducing the life and

accuracy of the device. Instead, use a stiff-bristled

brush to remove the chips and swarf, then wipe

down the surfaces with a clean shop rag.

Lubrication

Ball Oilers

Oil Type .... Grizzly T26685 or ISO 32 Equivalent

Oil Amount ......................................1 or 2 Squirts

Lubrication Frequency .............. Daily/Before Use

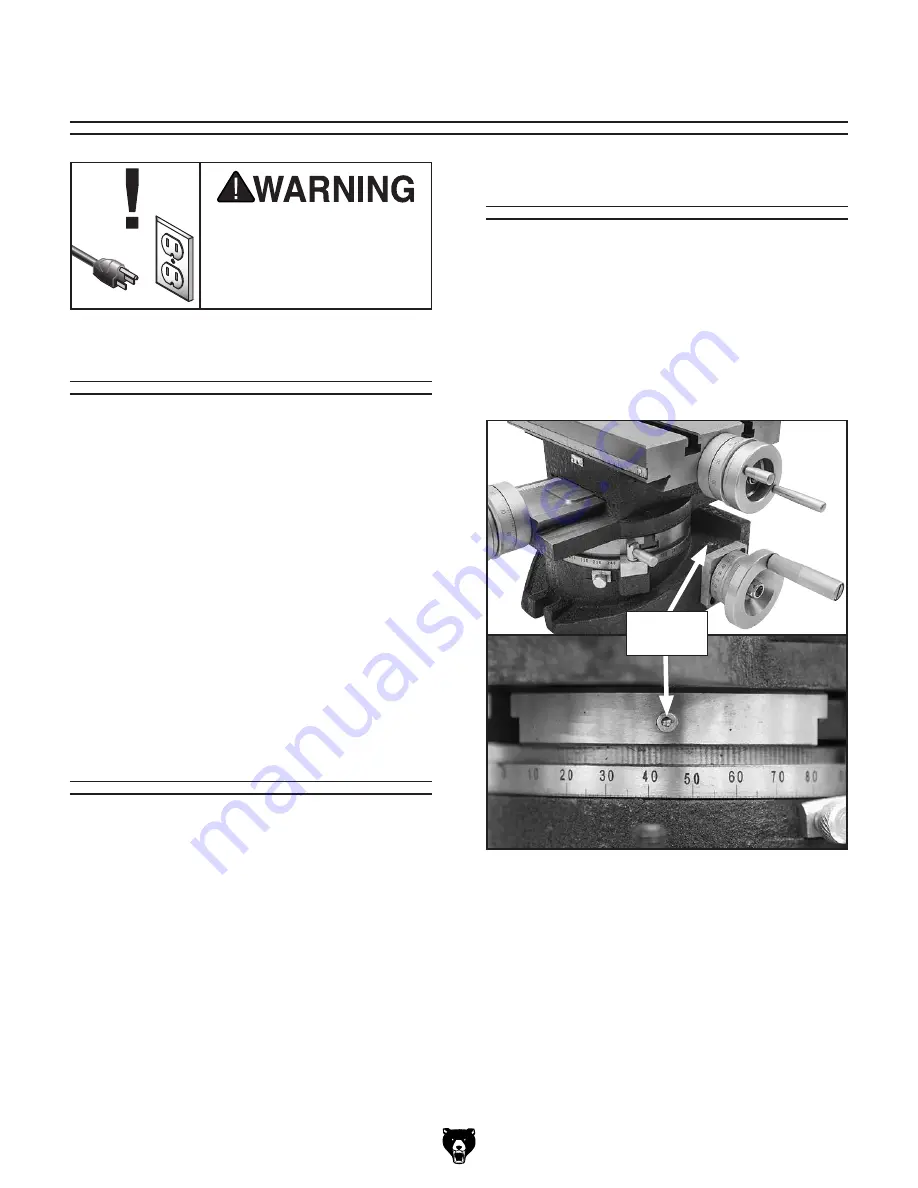

There are two ball oilers that should be oiled on a

daily basis, or before beginning operation. Refer

to

Figure 31 for their locations.

Lubricate the ball oilers with a pump-type can that

has a plastic or rubberized cone tip. We do not

recommend using metal needle or lance tips, as

they can push the ball too far into the oiler, break

the spring seat, and lodge the ball in the oil galley.

Clean the ball oiler before lubricating. Push the tip

of the oil can nozzle against the ball oiler to cre-

ate a hydraulic seal, then pump the oil can once

or twice. If sludge and contaminants come out,

pump the oil can until the oil runs clear. When

finished, wipe off excess oil.

Figure 31. Location of ball oilers.

Ball Oiler

Locations