-8-

Model T1243 (Mfd. Since 02/18)

SECTION 3: OPERATIONS

Operation Overview

The purpose of this overview is to provide the nov-

ice machine operator with a basic understanding

of how the machine is used during operation, so

the machine controls/components discussed later

in this manual are easier to understand.

Due to the generic nature of this overview, it is

not intended to be an instructional guide. To learn

more about specific operations, read this entire

manual, seek additional training from experienced

machine operators, and do additional research

outside of this manual by reading "how-to" books,

trade magazines, or websites.

To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

To reduce risk of eye injury from flying

chips or lung damage from breathing dust,

always wear safety glasses and a respirator

when operating this machine.

If you are not experienced with this type

of machine, WE STRONGLY RECOMMEND

that you seek additional training outside of

this manual. Read books/magazines or get

formal training before beginning any proj-

ects. Regardless of the content in this sec-

tion, Grizzly Industrial will not be held liable

for accidents caused by lack of training.

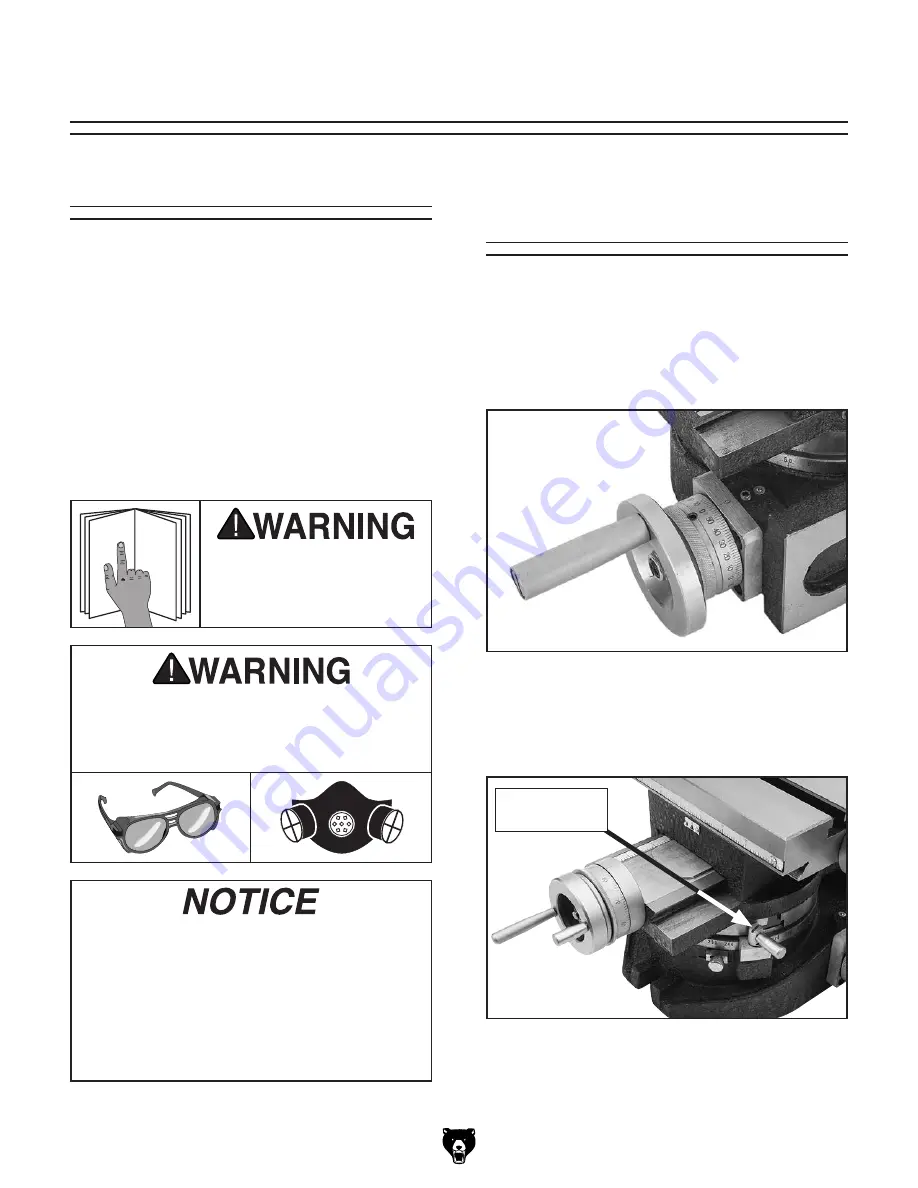

The T1243 rotary table rotates by turning the

3" handwheel, which is attached to a precision

worm gear engaged with a worm wheel. The ratio

between these gears is 90:1, which means one

complete turn of the handwheel rotates the table

4° (see

Figure 5).

To maximize rigidity during operation, the rota-

ry table has two table locks (see

Figure 6).

Tightening the levers locks the table in place.

Figure 5. Rotary table handwheel and scale.

To minimize finish problems associated with gear

backlash when cutting circular slots, lightly tighten

the locks to create extra drag.

Rotary Table

Movement

Figure 6. Rotary table lock.

Rotary Table

Lock (1 of 2)