-12-

Model T1243 (Mfd. Since 02/18)

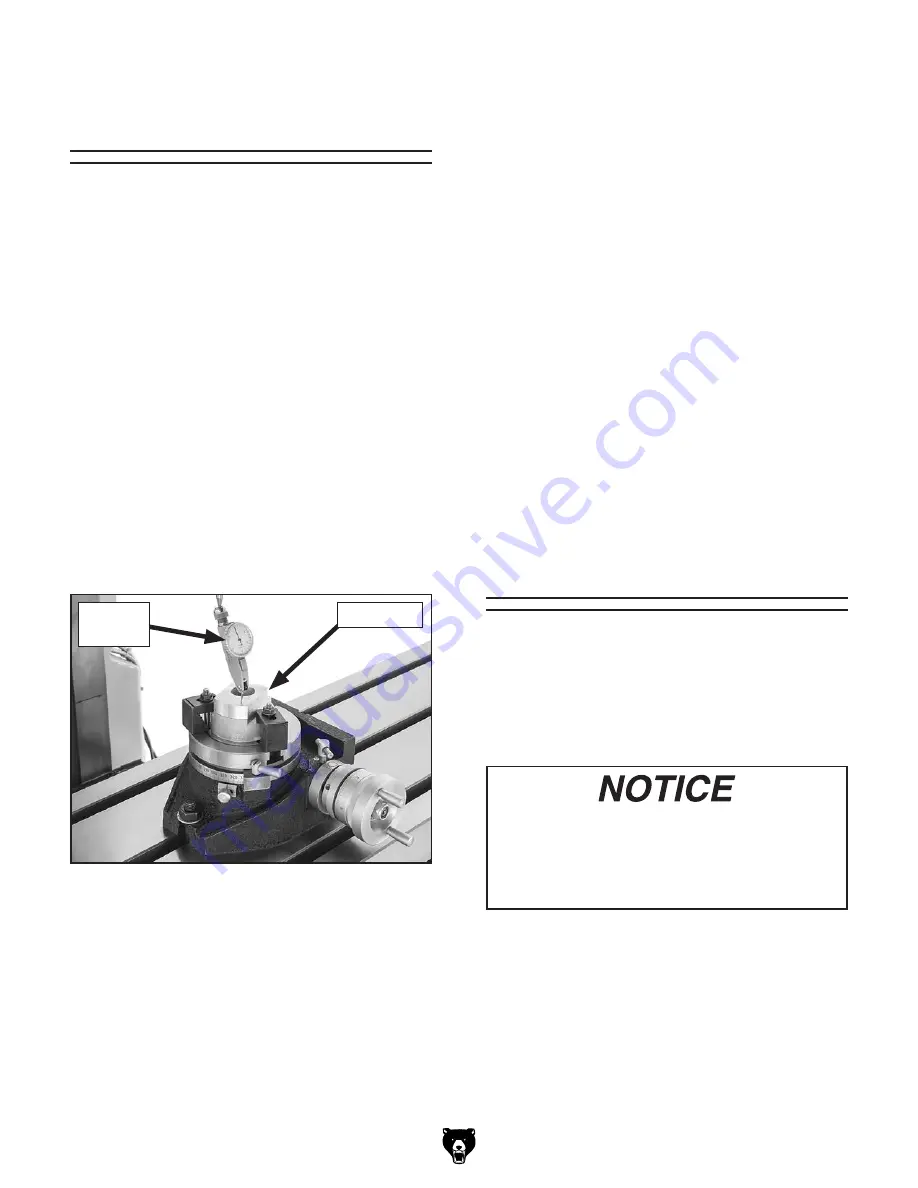

4. Adjust workpiece on table until there is zero

runout when table and workpiece are rotated,

then securely clamp workpiece to T1243

table.

5. Mount dial indicator in mill spindle using a

collet or chuck.

6. Indicate workpiece key feature, then rotate

mill spindle by hand in just one direction while

watching indicator dial.

Tip: Use a mirror to aid in reading test indica-

tor as it rotates away from you.

7. Adjust mill table until indicator dial reads zero

runout throughout rotation of spindle.

Note: If your workpiece is large enough, it

may be easier to use an edge finder instead

of a dial indicator.

Aligning Workpiece

with Mill Spindle

There are many ways to align the mounted

workpiece with the mill spindle. Review the sug-

gestions below, then use your best judgment

based on your experience and skills to select the

correct method for your operation.

3. Indicate inside or outside of workpiece, then

turn rotary table handwheel while watching

indicator dial.

Note: For accurate indicator results, turn

rotary table handwheel in just one direction

to eliminate any pinion backlash.

2. Position dial indicator with magnetic base

beside T1243, as shown in

Figure 16.

To align T1243 with mill spindle:

Items Needed

Qty

Dial Indicator with Magnetic Base ..................... 1

Precision Mandrel or Drill Rod .......................... 1

Edge Finder ....................................................... 1

Precision Square ............................................... 1

1. Mount T1243 horizontally on mill table under

spindle (see

Mounting Table Horizontally

on

Page 9).

Figure 16. Example of aligning workpiece using

a dial indicator.

Workpiece

Dial

Indicator

Aligning Table with

Mill Machine X-Axis

The T1243 should be aligned with the X-axis of

the milling machine. Mount the T1243 vertically

to the mill table using the supplied T-bolts and

hold-down clamps, or with parallel step blocks

and accessory step clamps (not included) (see

Mounting Table Vertically on Page 11).

To vertically mount T1243 to milling machine

tables with T-slots narrower than 5" or wider

than 6

1

⁄

2

" on center, or with T-slots wider

than

1

⁄

2

", use accessory step blocks and

clamps (not included).

Items Needed

Qty

Dial Indicator ..................................................... 1

Hold-Down Clamps ........................................... 2

Parallel Step Blocks (Not Included) ................... 2

Accessory Step Clamps (Not Included) ............ 2