-72-

Model G0899 (Mfd. Since 10/20)

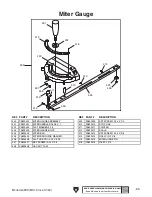

Figure 126. Fence components used to adjust

fence height and squareness to table.

Lock Nut

Fence Flange

Knob

(1 of 3)

Rear Rail

Foot

Top

Adjustment Screws

Figure 128. Example of aligning fence to miter

slot.

Fence

Face

Miter

Slots

Top View

Overlap

Side View (Bad)

Flush

Side View (Good)

A

B

The rear set screws control the position of the

fence in relation to the blade and the clamping

pressure of the fence. Before starting this pro-

cedure, make sure the blade is parallel with the

miter slot.

To adjust fence parallelism and clamping

pressure:

1. DISCONNECT MACHINE FROM POWER!

2. Lock fence, tap front side with your fist, and

check to see if it moved sideways over table.

— If fence did not move, proceed to

Step 5.

— If fence moved, remove it from table and

proceed to

Step 3.

3. Turn each rear set screw in

1

⁄

6th

of a turn (see

Figure 125 on Page 71). Glide pads on fence

flange should just touch fence tube.

4. Re-install fence and repeat Step 2.

5. Slide fence against right-hand edge of miter

slot and lock it in place, as shown in

Figure

128.

Parallelism & Clamping Pressure

6. Turn top adjustment screws and rear foot

screw so there is approximately

1

⁄

16

" clear-

ance between bottom of fence and table,

front-to-back and side-to-side, then tighten

lock nuts.

7. Place square on table and against face of

fence, as shown in

Figure 127, to check if

fence is square to table.

— If fence is square to table, proceed to

Parallelism & Clamping Pressure.

— If fence is not square to the table, proceed

to

Step 8.

Figure 127. Checking if fence is square to table.

90° Square

Fence

Table

8. Loosen top lock nuts and adjust top screws

(see

Figure 126) to make fence face 90° to

table, then tighten lock nuts.

4. Install fence onto table, then loosen fence

knobs (see

Figure 126), pull fence up from

center, and tighten each knob.

5. Loosen top lock nuts on fence flange and lock

nut on rear rail foot, shown in

Figure 126.

Содержание G0899

Страница 92: ......