-42-

Model G0899 (Mfd. Since 10/20)

Dado blades have a higher risk of kickback

than normal blades because their larger size

applies stronger forces to the workpiece.

This risk increases relative to the depth and

width of the cut. To minimize your risk of

serious personal injury, ensure that stock

is flat and straight, and make multiple light

cuts (rather than one deep cut) to achieve

the desired cutting depth.

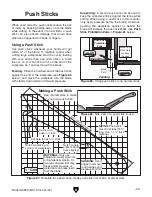

Figure 65. Example of dado being cut with

multiple light cuts, instead of one deep cut.

The

Figure below demonstrates the sequential

process of making multiple, light cuts that get

progressively deeper. The actual number of cuts

used should be determined by workpiece hard-

ness, total dado depth, and feed rate. In general,

if you hear the motor slow down during the cut,

you are cutting too deep or feeding too fast. Slow

down!

Dado Blade

Workpiece

Fence

Cut 1

Workpiece

Fence

Cut 2

Workpiece

Fence

Cut 3

Finished

Dado Cut

Workpiece

Fence

To cut a dado with a dado blade:

1. DISCONNECT MACHINE FROM POWER!

2. Adjust dado blade to desired depth of cut.

3. Adjust distance between fence and inside

edge of blade, as shown in

Figure 64 on

Page 41, to dado length of a workpiece.

—

If dadoing across workpiece, use miter

gauge and carefully line up desired cut

with dado blade. To reduce kickback, DO

NOT use fence in combination with miter

gauge.

4. Reconnect saw to power source.

5. Turn saw ON. Blade should run smoothly,

with no vibrations.

6. When blade has reached full speed, perform

test cut with scrap piece of wood.

7. If cut is satisfactory, repeat cut with actual

workpiece.

A ripping blade (described on

Page 39) is typically

the best blade to use when cutting dadoes with a

standard blade because it removes sawdust very

efficiently.

To use a standard saw blade to cut dadoes:

1. DISCONNECT MACHINE FROM POWER!

2. Mark width of dado cut on workpiece. Include

marks on edge of workpiece so cut path can

be aligned when workpiece is lying on table.

Cutting Dadoes with a Standard

Blade

3. Raise blade up to desired depth of cut (depth

of dado channel desired).

4. Set saw up for type of cut you need to make,

depending on whether it is a rip cut (see

Page 39) or crosscut (see Page 40).

Cutting Dadoes with a Dado Blade

Because dado blades are much wider than stan-

dard blades, they place a greater amount of force

against the workpiece when cutting. This addition-

al force increases the risk of kickback, requiring

the operator to take additional steps when cutting

to keep their injury risk at an acceptable level.

Содержание G0899

Страница 92: ......