Model G0899 (Mfd. Since 10/20)

-35-

Spreader

The spreader is a metal plate that prevents the

newly cut kerf of the workpiece from pinching the

backside of the blade and causing kickback.

The spreader also acts as a barrier behind the

blade to shield hands from being pulled into the

blade if a kickback occurs.

In order to work properly, the spreader

cannot be bent or misaligned with the blade.

If the spreader gets accidentally bent, take

the time to straighten it or just replace it.

Using a bent or misaligned spreader will

increase the risk of kickback! Refer to Page

69 to check or adjust alignment if necessary.

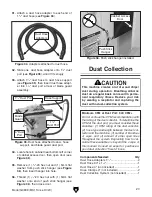

Installing Blade Guard & Spreader

3. Adjust flat head cap screws (see Figure 52)

to make sure table insert is flush with table

(use a straightedge as a guide).

Note: The blade guard, when properly

installed, should be set up similarly to

Figure

52. It should pivot freely up and down and

return to the table in the resting position. It

should also swing up high enough to accom-

modate the workpiece.

Tools Needed

Qty

Hex Wrench 3mm .............................................. 1

Straightedge ...................................................... 1

To install blade guard and spreader:

1. DISCONNECT MACHINE FROM POWER!

2. Slide end of spreader between adjustment

block and clamping plate. Press firmly until

spreader snaps into place (see

Figure 51).

Figure 52. Blade guard installed.

Flat Head Cap Screw (1 of 4)

Figure 51. Spreader held between clamping

plate and adjustment block.

Clamping

Plate

Содержание G0899

Страница 92: ......