-42-

Model G0819 (Mfd. Since 09/16)

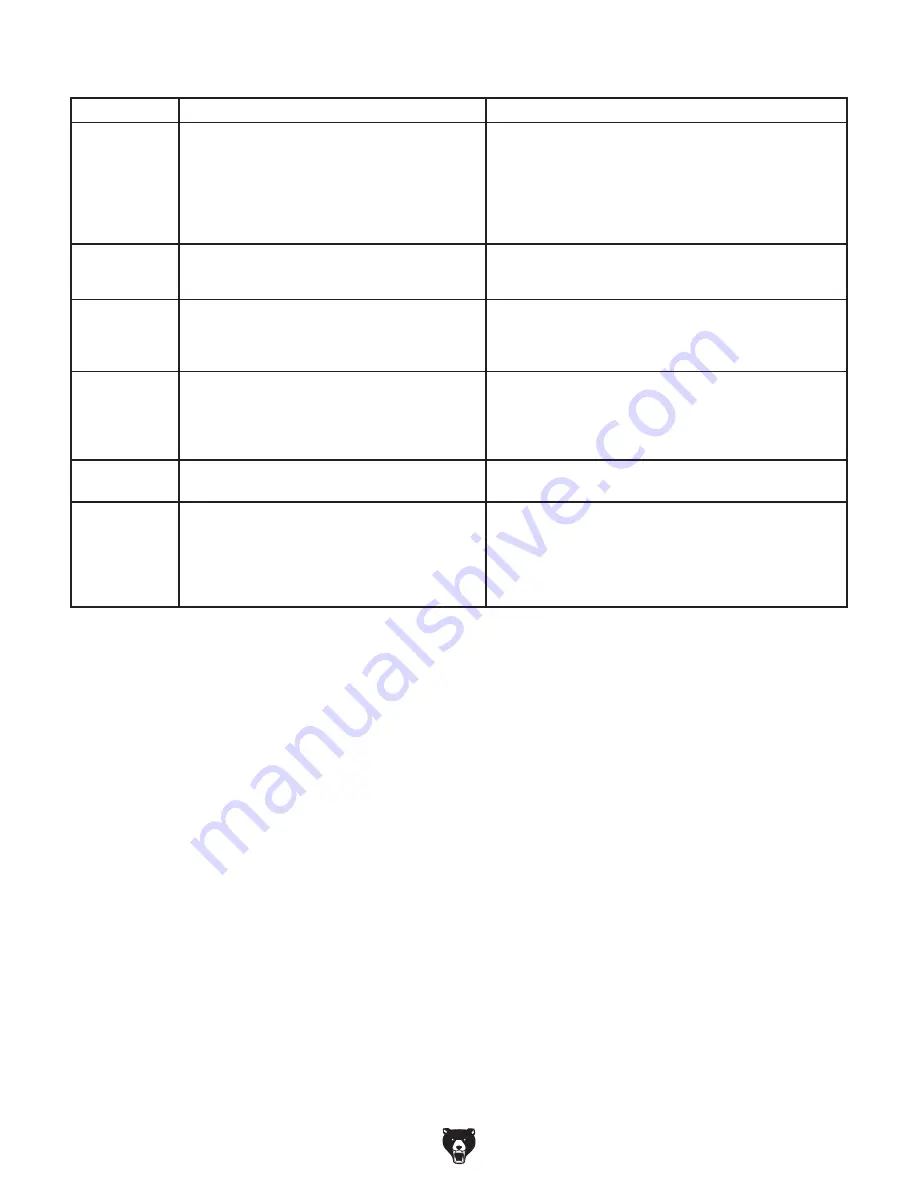

Symptom

Possible Cause

Possible Solution

Sanding belt

will not start,

but conveyor

will.

1. No air pressure to sander.

2. Airflow adjustment valve closed.

3. Limit switches engaged.

4. Emergency stop plate engaged.

5. Sanding belt not tensioned.

1. Connect sander to compressed air system (

Page 20

).

2. Open airflow adjustment valve.

3. Center sanding belt so it is not touching limit switches

(

Page 57

).

4. Make sure emergency stop plate is released

(

Page 29

).

5. Tension sanding belt (

Page 26

).

Conveyor belt

not tracking in

center.

1. Conveyor belt moved out of adjustment.

1. Adjust conveyor adjustment bolts (

Page 55

).

Conveyor belt

slipping.

1. Conveyor rollers have incorrect tension.

2. Conveyor rollers contaminated with dirt or

dust.

1. Adjust conveyor rollers to place more tension on

conveyor belt (see

Page 55).

2. Clean conveyor rollers.

Emergency

brake stops

slowly.

1. Low air pressure.

2. Air leaks in system.

3. Brake rotor contaminated with oil.

4. Brake pads worn out.

1. Adjust incoming air pressure to 75 PSI (

Page 20).

2. Inspect all hoses and connections for leaking air; use

water on suspected area to detect bubbles.

3. Clean brake rotor with automotive brake parts cleaner.

4. Replace brake pads (

Page 45

).

Grinding noise

when braking.

1. Brake pads worn out.

1. Replace brake pads (

Page 45), have rotor turned/

trued by a machine shop. Replace rotor.

Air leaking from

sander.

1. There is no problem. It is normal to hear an air

leaking sound coming from the machine.

2. Water filter/trap drain cock left open.

3. Air line ruptured or air leaking at a connection

point.

1. Unless there is clear evidence of an air leak or a per-

formance problem with belt oscillation or braking time,

take no action.

2. Ensure

water filter/trap drain cock is tight.

3. Find source of sound and determine likely cause based

on what you see.

Operation Continued

Содержание G0819

Страница 84: ......