Model G0819 (Mfd. Since 09/16)

-27-

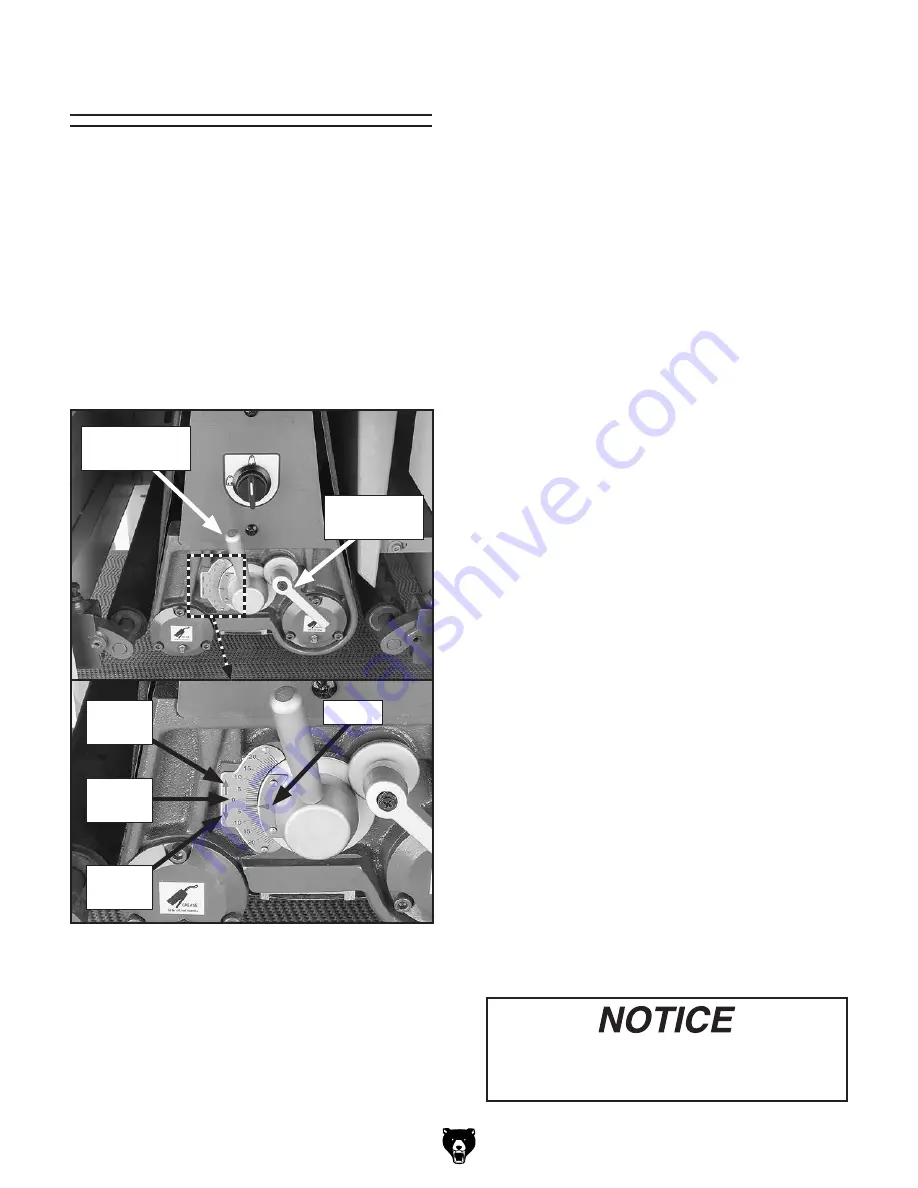

Adjusting Platen

If workpiece has straight notches across it,

graphite cloth and felt have worn out and

need to be replaced immediately.

Unlike the sanding belt, which typically produces

short but deep scratch patterns, the platen pro-

duces long and shallow scratch patterns that

create a smoother finish. Due to its cushioned-

construction, the platen is less likely to leave belt-

splice or chatter marks.

However, we do not recommend lowering the

platen depth more than 2mm or over-using the

platen by expecting it to remove marks beyond its

ability to do so, since this can reduce the life of the

sanding belt and platen, and result in premature

streaking.

Tip: Given the short life-span of most graphite

pads, it is a good idea to keep replacement pads

on hand.

Platen Up: The platen is raised above the level

of the drums (typically set at 1.5mm UP), so

only the sanding drums are making contact with

the workpiece. This position is typically used

for heavy sanding passes or dimensioning. The

drums do all the work, but you will have a rough

finish. Typically platens are used in this position

with #100 or coarser grit.

Platen Even: The platen is set level with the

drums. This position is used for intermediate-fin-

ishing passes. The depth of cut should not exceed

0.010". This position typically uses #100–#150

grit.

Platen Down: The platen is set below the level of

the drums so it is the primary contact point while

performing finish sanding.

The platen should be lowered to 0.2 to 0.5mm

(maximum) below the sanding drums, but not

more than 0.2mm per pass. You can lower the

platen up to 2 mm below the drums for short inter-

vals, but streaking, burn marks, and premature

graphite/platen wear can occur if this setting is

abused or over-used.

It is not necessary to use the table height

handwheel to adjust the sanding depth during the

final sanding pass—the platen movement alone

will take care of the depth of cut. Typically the

final-sanding pass position uses #180 or finer.

Note: The platen scale is broken down in 0.1mm

increments (approximately 0.004").

Figure 33. Platen height scale controls and

positions.

Platen Height

Lever

Platen Lock

Lever

Pointer

This sander is equipped with an adjustable platen

with a graphite pad that is designed to be used

during finish sanding to create a polished-type

finish and to prepare the workpiece for orbital

sanding or a finish coat.

The platen position allows for 3 basic types of

sanding: up, even, and down, which are adjusted

by unlocking the platen lock lever and rotating the

scale pointer arrow with the height lever shown

in

Figure 33

to the desired position. The setting

is secured for the sanding operation with the lock

lever.

Up

Position

Even

Position

Down

Position

Содержание G0819

Страница 84: ......