Model G0817 (Mfd. Since 05/16)

-57-

Operating Machine (Continued)

Symptom

Possible Cause

Possible Solution

Finished

workpieces are

rough or show

scoring.

1. Blade is overloaded and twists.

2. Blade TPI is too coarse.

3. Blade is loose and fluttering.

4. Blade tracking is incorrect.

5. Blade has missing/bent teeth, or faulty weld.

1. Decrease feed rate; ensure proper TPI (

Page 44).

2. Use correct blade for material and speed of cut

(

Page 41).

3. Adjust blade tension as required (

Page 28).

4. Adjust blade tracking (

Page 25).

5. Replace blade (

Page 46).

Table is hard to

tilt.

1. Table tilt lock lever is engaged.

2. Sawdust or pitch trapped between trunnion and

base.

3. Metal burrs on trunnion.

1. Disengage table tilt lock lever (

Page 47).

2. Remove table and clean trunnion sliding surfaces

free of sawdust or pitch.

3. Remove burrs.

Table does not tilt

to 45 or 0 degrees.

1. Table tilt scale pointer not calibrated.

2. Positive stop not set correctly.

1. Calibrate table tilt scale pointer (

Page 69).

2. Adjust positive stop (

Page 47).

Miter bar binds in

miter slot.

1. Miter slot dirty or gummed up.

2. Miter bar is bent.

1. Carefully clean miter slot.

2. Replace.

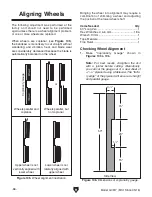

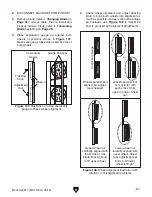

Blade tracks

incorrectly, or

comes off wheels.

1. Tracking is not adjusted properly.

2. Wheels are not coplanar.

3. Blade tension too loose.

4. Blade guides/support bearings improperly

adjusted.

5. Feeding workpiece too fast.

6. Incorrect blade for operation.

7. Blade is bell-mouthed, worn, or dull.

8. Rubber tire or wheel is damaged or worn.

1. Adjust tracking (

Page 25).

2. Adjust wheels to be coplanar (

Page 66).

3. Increase blade tension (

Page 28).

4. Properly adjust blade guides/support bearings

(

Pages

31

–

33).

5. Feed workpiece slower.

6. Install correct blade (

Page 41).

7. Install new blade and remove tension from blade

when not in use.

8. Replace rubber tires or wheel.

Cut is crooked or

blade wanders

(blade lead).

1. Excessive feed rate/pressure.

2. Blade tension too loose.

3. Blade is too narrow or tooth type/TPI is

incorrect for the cut.

4. Inadequate blade support.

5. Blade dull or has damaged tooth set from

improper guides/support bearing adjustment.

6. Blade tracking is incorrect.

7. Table is loose.

8. Fence or miter slot out of alignment with blade.

9. Blade guides/support bearings improperly

adjusted.

10. Tooth set is uneven or teeth are more sharp on

one side than the other.

1. Reduce feed rate/pressure.

2. Increase blade tension (

Page 28).

3. Use wider blade. Ensure tooth type & TPI is

correct. (

Page 41).

4. Position upper blade guides to just clear

workpiece. Properly adjust blade guides/support

bearings (

Pages

31

–

33).

5. Replace blade (

Page 46).

6. Adjust blade tracking (

Page 25).

7. Tighten table trunnion mounting bolts or tilt lock

lever.

8. Align table miter slot and fence with blade (

Pages

36–37).

9. Properly adjust blade guides/support bearings

(

Pages

31

–

33).

10. Replace blade (

Page 46).

Blade dulls

prematurely.

1. Excessive feed rate/pressure.

2. Wrong blade tooth type or TPI.

3. Blade is twisted.

4. Blade is slipping on wheel.

5. Blade guides hitting teeth and ruining tooth set.

1. Reduce feed rate/pressure.

2. Use blade with correct tooth type and TPI.

(

Page 41).

3. Re-install blade; replace (

Page 46).

4. Adjust blade tension (

Page 28).

5. Properly adjust guide bearings (

Page 32).

Содержание G0817

Страница 88: ......