-60-

Model G0812 (Mfd. Since 2/16)

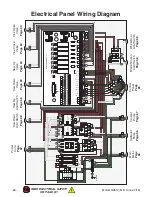

Figure 97. Using 60° square to check 60° left

angle stop.

— If square fits snugly against outer fixed jaw

and blade, no further steps are necessary

.

— If square does not fit snugly against outer

fixed jaw and blade, loosen jam nut shown

in

Figure 94 on Page 59. Thread stop

bolt inward or outward as necessary, until

square fits snugly against fixed jaw base

while base contacts stop bolt.

8. Tighten jam nut without turning stop bolt.

1. Repeat Steps 1–3 from Setting 45° Right

Angle Stop on Page 59.

2. Rotate swivel lock handle toward base, then

rotate headstock clockwise until base con-

tacts 60° left stop bolt (see

Figure 96).

Setting 60° Left Angle Stop

3. Slide vise to right position and secure it. Refer

to

Changing Vise Position on Page 34.

4. Connect machine to power and lower head-

stock all the way until it stops moving.

Figure 96. 60° left stop bolt and jam nut location.

5. DISCONNECT MACHINE FROM POWER

and place 60° square between outer fixed

jaw and blade, as shown in

Figure 97. The

square should fit snugly against outer fixed

jaw and blade.

— If square fits snugly against outer fixed jaw

and blade, no further steps are necessary

.

— If square does not fit snugly against outer

fixed jaw and blade, loosen jam nut shown

in

Figure 96. Thread stop bolt inward or

outward as necessary until square fits

snugly against outer fixed jaw and blade

while base contacts stop bolt.

6. Tighten jam nut without turning stop bolt, then

tighten swivel lock handle to secure head-

stock.

60° Left Stop Bolt

Jam Nut

Blade

60°

Square

Outer Fixed Jaw

Содержание G0812

Страница 84: ......