WIRING

Page 32

© 2013 Greenwood Clean Energy, Inc All Rights Reserved V1.9

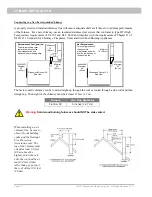

Power Outage and Overheat Protection

The Frontier Series, like all solid fuel boilers, does not stop generating heat when power is interrupted. The

Thermsafe

TM

Overheat Cooling System engages and prevents a boil over in the event of power failure or an

excessive sudden drop in heat demand from the home.

The Thermsafe system, which is controlled by the Greenwood Boiler Management logic, shuts down

combustion and enables gravity fed cooling through the expansion tank when the power goes out or the

outlet temperature rapidly rises beyond the set point. If the power has not been lost, combustion will resume

after a minimum ‘time out’ of 5 minutes and a drop in outlet temperature to 20

o

F below the set point.

POWER OUTAGE WARNINGS:

DO NOT

open the firebox door during a power outage;

doing so may cause a backflow of smoke into the furnace area.

DO NOT

block open the air

intake dampers; doing so may cause the furnace to overheat, damaging components and

voiding your warranty.

Содержание Frontier CX

Страница 1: ......

Страница 3: ...This page intentionally left blank...

Страница 4: ......

Страница 8: ...SAFETY Page 4 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 SAFETY WARNINGS LABEL...

Страница 9: ...SAFETY 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 Page 5 LABEL LOCATIONS...

Страница 10: ...SAFETY Page 6 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 This page intentionally left blank...

Страница 29: ...PLUMBING INSTALLATION 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 Page 25 Pi ping Schematics...

Страница 30: ...PLUMBING INSTALLATION Page 26 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9...

Страница 35: ...WIRING 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 Page 31...

Страница 54: ...WA This page intentionally left blank...

Страница 56: ...This page intentionally left blank...

Страница 57: ...This page intentionally left blank...