INTRODUCTION

Page 8

© 2013 Greenwood Clean Energy, Inc All Rights Reserved V1.9

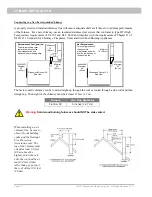

Air Flow through the Furnace

1.

Under-Fire Zone:

Under-fire air entering through the pinhole grate combined with heat drives the

rate of pyrolysis (the release of gases from the wood fuel).

2.

Combustion Zone:

750 lbs (340 kg) of refractory reflect energy back into combustion chamber

maintaining optimum combustion temperatures.

3.

Crossfire Zone:

Over-fire air is added following the separation of gases from the wood pile.

4.

Burn-Out Zone:

Combustion is completed in the burn-out zone where gas temperatures reach 2000

o

F (1100

o

C).

5.

Heat Transfer Zone:

Heat is transferred from the hot combustion gasses to the water-tube heat

exchanger in an isolated chamber. This is the only area where heat is transferred to water.

6.

Exhaust Zone:

Exhaust gases leave the boiler at temperatures of 200 – 450

o

F (93

o

C to 205

o

C)

depending on firing rate.

Side View of Air Flow through the Frontier CX

Содержание Frontier CX

Страница 1: ......

Страница 3: ...This page intentionally left blank...

Страница 4: ......

Страница 8: ...SAFETY Page 4 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 SAFETY WARNINGS LABEL...

Страница 9: ...SAFETY 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 Page 5 LABEL LOCATIONS...

Страница 10: ...SAFETY Page 6 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 This page intentionally left blank...

Страница 29: ...PLUMBING INSTALLATION 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 Page 25 Pi ping Schematics...

Страница 30: ...PLUMBING INSTALLATION Page 26 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9...

Страница 35: ...WIRING 2013 Greenwood Clean Energy Inc All Rights Reserved V1 9 Page 31...

Страница 54: ...WA This page intentionally left blank...

Страница 56: ...This page intentionally left blank...

Страница 57: ...This page intentionally left blank...