10. INSTALLATION AND MAINTENANCE

GEK-106243E

DTP Digital Transformer Protection

10-1

10. INSTALLATION AND MAINTENANCE

10.1 INSTALLATION

The relay should be installed in a clean, dry and dust-free place, with no vibrations. It should also be well lit to

facilitate inspection and testing.

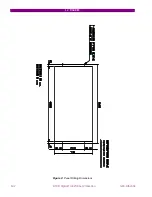

The relay should be mounted on a vertical surface. Figure 2 shows the diagram for panel drilling for panel

mounting.

Given that the design of the SMOR unit is based on high performance digital technology it is not necessary to

recalibrate the relay. However if the tests show that it is necessary to readjust the relay, it is recommended that

the unit should be returned to the manufacturer to have this done.

10.2 CONNECTION TO GROUND AND SUPPRESSION OF DISTURBANCES

Terminal P12 (see figure 6) should be connected to ground so that the disturbance suppression circuits in the

system work correctly. This connection should be as short as possible (preferably 25 cm or less) to guarantee

maximum protection. In this way the capacitors which are internally connected between the inputs and ground

divert high frequency disturbances directly to ground without passing through the electronic circuits, with the result

that the circuits are perfectly protected.

In addition this connection also guarantees the physical safety of the personnel who have to touch the relay, since

the whole casing is connected to ground.

10.3 MAINTENANCE

Given the important role that the protection relays play in the operation of any installation, a periodic program of

tests is highly recommended. The unit incorporates built-in diagnostic functions which permit immediate

identification with only the aid of the keyboard and display, the detection of some of the most likely circuit failures.

Testing the unit is recommended at intervals of 2 years or more. Although the built-in diagnosis does not reduce

the average time between failures, it does increase the availability of the protection because it allows a drastic

reduction in the average interruption time involved in detecting and repairing the fault.

The set of tests which can be carried out to test that all the features of the DTP unit function properly is described

in detail in the chapter entitled ACCEPTANCE TESTS.

Since most of the protection and communications functions are integrated in two separate programs, it is unlikely

that faults will occur due to problems of wear or ageing which are typical in electromechanical, analog or hybrid

protection systems. Moreover, a failure in the communications processor does not affect the protection functions,

which are implemented by a dedicated processor.

Содержание DTP-B

Страница 23: ...3 OPERATING PRINCIPLES 3 6 DTP B Digital Transformer Protection GEK 106243E ...

Страница 53: ...10 INSTALLATION AND MAINTENANCE 10 2 DTP B Digital Transformer Protection GEK 106243E ...

Страница 66: ...12 FIGURES GEK 106243E DTP Digital Transformer Protection 12 1 12 FIGURES Figure 1 External Connections ...

Страница 67: ...12 FIGURES 12 2 DTP B Digital Transformer Protection GEK 106243E Figure 2 Panel Drilling Dimensions ...

Страница 68: ...12 FIGURES GEK 106243E DTP Digital Transformer Protection 12 3 Figure 3 RS 232 Connection ...

Страница 69: ...12 FIGURES 12 4 DTP B Digital Transformer Protection GEK 106243E Figure 4 Dimensions Diagram ...

Страница 70: ...12 FIGURES GEK 106243E DTP Digital Transformer Protection 12 5 Figure 5 Front View ...

Страница 73: ...12 FIGURES 89 DTP B Digital Transformer Protection GEK 106243E Figure 8 Block Diagram of the Protection ...