Section 5 Component Teardown

5-10

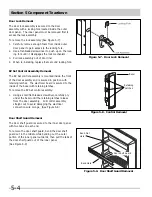

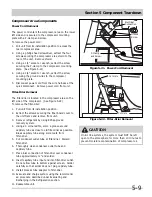

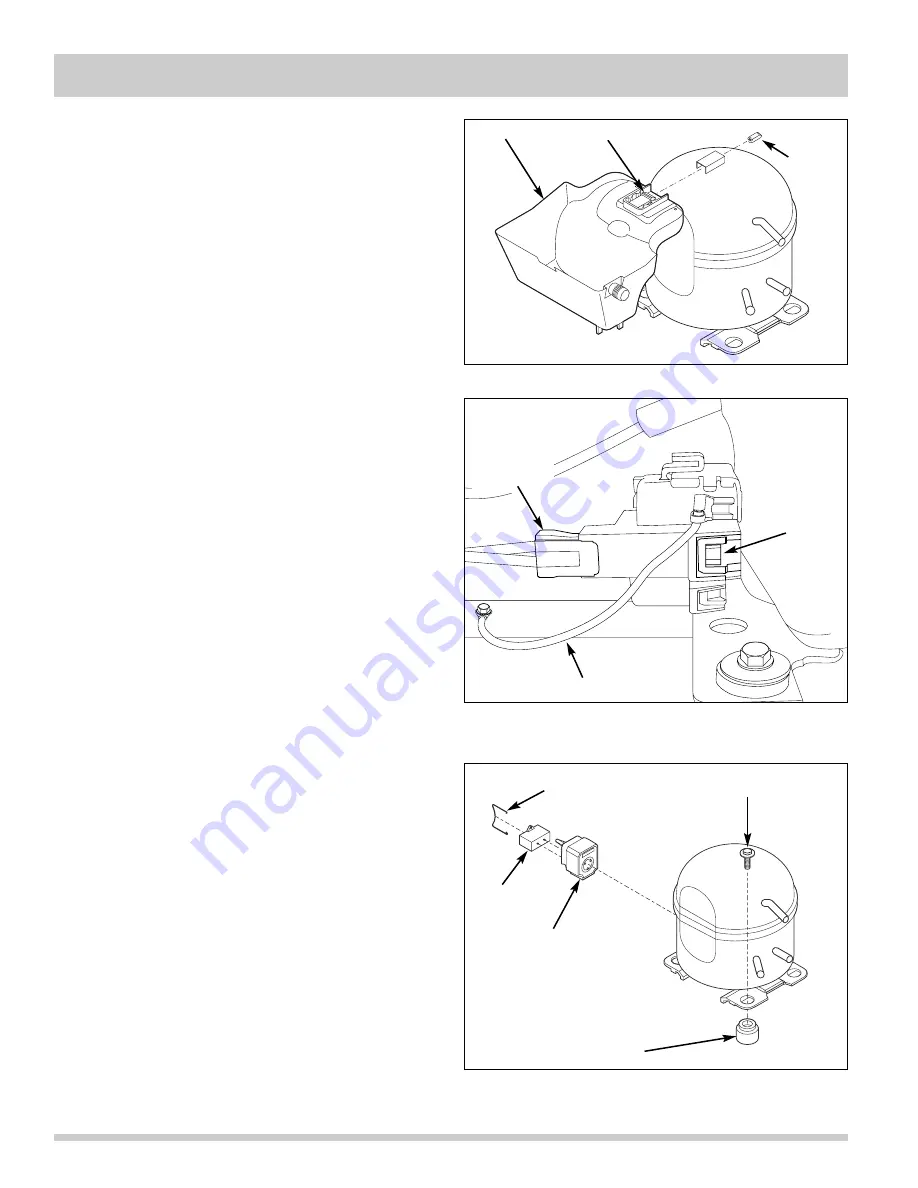

Figure 5-24. Compressor Electrical Component

Removal

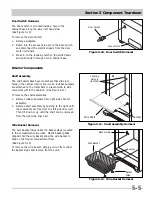

Figure 5-25. Compressor Components

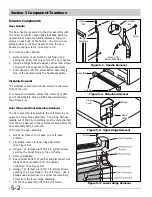

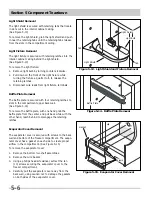

Figure 5-23. Drain Pan Removal

Ground Wire

Retaining

Latch

Wire Harness

Connection

Spring Wire

Screw

Capacitor

Controller

Grommet

Drain Pan

Latch

Clip

Drain Pan

The drain pan is mounted to a bracket mounted to the

top of the compressor. (See Figure 5-23)

To remove the drain pan:

1. Pull unit from its installation position.

2. Extract the screws securing the fiber board cover to

the unit frame and remove from unit.

3. Using a pliers, remove the retaining clip securing the

drain pan to the top of the compressor.

4. Pull drain pan off compressor, remove drain hose

and remove from unit.

Compressor Removal

The compressor sits on four grommets and is secured

with four screws to the compressor mounting plate.

(See Figure 5-24 & 5-25)

To remove the filter-drier:

1. Pull unit from its installation position.

2. Extract the screws securing the compressor shield to

the unit frame and remove from unit.

3. Using a small flat bladed screwdriver, release the

locking tab from the wire harness connection and

disconnect from compressor controller.

4. Using a needlenose pliers, remove spring wire

holding the controller to the compressor.

5. Recover refrigerant by using EPA approved

recovery system.

6. Using a 7/16” socket, remove the (4) bolts, one in

each corner, holding the compressor to the base.

(See Figure 5-24)

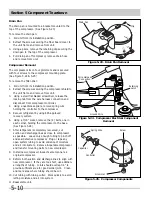

7. After refrigerant is completely recovered, cut

suction and discharge lines as close to compressor

as possible. Leave only enough tubing to pinch off

and seal defective compressor. Plug or tape any

open system tubing to avoid entrance of moisture

and air into system. Remove inoperable compressor

and transfer mounting parts to new compressor.

8. Install new compressor inexact same manner as

original compressor.

9. Reform both suction and discharge lines to align with

new compressor. If they are too short, use addition-

al lengths of tubing. Joints should overlap 0.5” to

provide sufficient area for good solder joint. Clean

and mark area where tubing should be cut.

10. Cut tubing with tubing cutter. Work quickly to avoid

letting moisture and air into system.

11. Reassemble unit.

Содержание FFH17F8HW0

Страница 2: ......

Страница 14: ...Section 2 Installation Information 2 6 Notes ...

Страница 18: ...Section 3 Electronic Control 3 4 Notes ...

Страница 33: ...Section 4 Refrigeration 4 15 HFC 134a CFC 12 Pressure Temperature Chart ...

Страница 36: ...Section 4 Refrigeration 4 18 Notes ...

Страница 48: ...Section 5 Component Teardown 5 12 Notes ...

Страница 53: ...Section 7 Wiring Diagram 7 1 ...

Страница 54: ...Section 7 Wiring Diagram 7 2 Notes ...