Section 4 Refrigeration

4-12

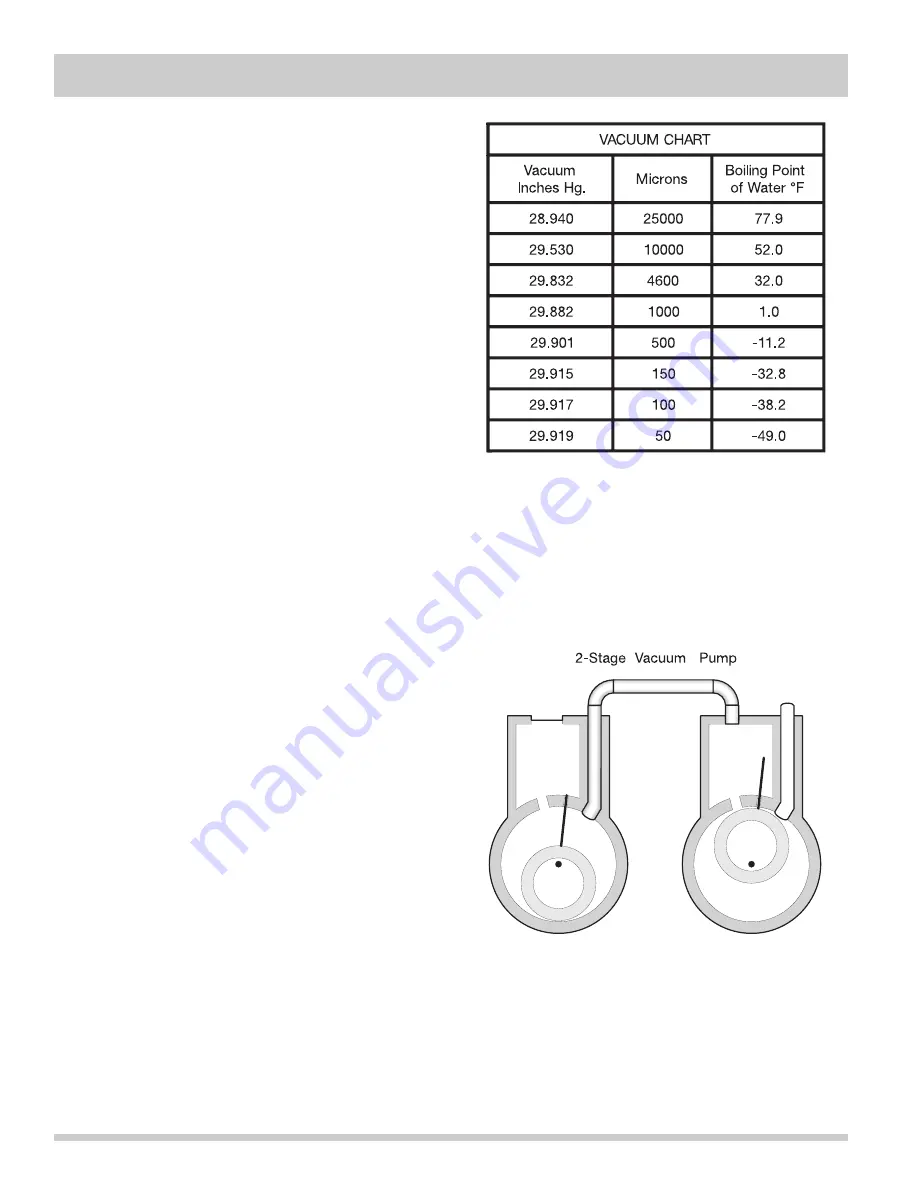

To achieve the required 29.9 inch (500 micron) vacuum,

a properly maintained two-stage vacuum pump in good

condition is required. A two stage pump can reach a

deeper vacuum than a single stage because the exhaust

from the first pumping stage is discharged into the sec-

ond pumping stage. This means the second stage

begins pumping at a lower pressure so a lower ultimate

vacuum can be achieved.

For example, hoses that were used for a refrigeration

system operating on R-12 may contain small quantities

of mineral oil which can block the capillary tube in a

system operating on R-134a. As little as one milligram

may be sufficient to cause a blockage. In addition,

sealed system components that have been used with

CFC systems must not be used with R-134a systems.

These components may contain residual amounts of

refrigerant and oil which could damage an R-134a

system.

At the earliest stage of development work on R-134a,

tests were carried out on a different type of synthetic oil

known as Poly-Alkaline Glycol (PAG). This oil is also

used in certain air conditioning systems for cars.

PAG and Ester oil DO NOT mix with one another. Service

equipment used for R-134a / Ester oil must not come

into contact with PAG.

Water In The Refrigeration System

Even in very small quantities, water in any refrigeration

system can cause the following problems:

•

Ice plugs in capillary tubes.

•

Copper plating in compressor.

•

Reactions with organic materials in systems.

•

Corrosion of metals.

R-134a and Ester oil will aggravate the problem of water

in the refrigeration system. Ester oil may react with

water vapor and is hygroscopic (it will absorb water if it

comes in contact with humid air). Water is also more

soluble in R-134a than R-12.

To minimize the water content whenever service work is

performed, the refrigeration system should always be

thoroughly evacuated through process tube adapters on

both the high and low sides of the system. Evacuation

must be for a minimum of 30 minutes to at least a 29.9

inch (500 micron) vacuum.

Содержание FFH17F8HW0

Страница 2: ......

Страница 14: ...Section 2 Installation Information 2 6 Notes ...

Страница 18: ...Section 3 Electronic Control 3 4 Notes ...

Страница 33: ...Section 4 Refrigeration 4 15 HFC 134a CFC 12 Pressure Temperature Chart ...

Страница 36: ...Section 4 Refrigeration 4 18 Notes ...

Страница 48: ...Section 5 Component Teardown 5 12 Notes ...

Страница 53: ...Section 7 Wiring Diagram 7 1 ...

Страница 54: ...Section 7 Wiring Diagram 7 2 Notes ...