14

Pre-Commissioning Settings

FFRT Set-Up Description

Using the keypad the scanner flame failure response time can be set by the user to the desired timing.

Each unit comes from the factory pre-set at 1 second.

To change the factory default to a different

FFRT see Set-Up Procedure below. To verify the current FFRT setting, press and hold the UP push

button with the scanner in the normal operating mode. The “flame strength” LED set will display 1

st

,

2

nd

, 3

rd

or 4

th

LED as appropriate and these correspond to the FFRT in seconds.

FFRT Set-Up Procedure

If the Flame Failure Response Time needs modifying, follow the procedure listed below.

Press both the

Target Flame Select

and

Background Flame Select

buttons simultaneously.

Use the up button to drive the LEDs until LED number

[8]

(pass code) is illuminated on the flame strength

LEDs right hand set.

Press both the

Target Flame Select

and

Background Flame Select

buttons simultaneously.

Press UP or DOWN push buttons to select required FFRT (the selected FFRT is displayed on the flame

strength LEDs as either

1

st

, 2

nd

, 3

rd

or 4

th

). Once you have selected the correct value, Press both the

Target Flame Select

and

Background Flame Select

buttons simultaneously to store. The stored value

can be displayed and checked at any time while in the normal run mode. Pressing and holding the UP

pushbutton at any time will display the stored FFRT on the flame LEDs right hand set. Verify that the

correct FFRT has been stored.

Commissioning the Scanner /Learning the Flame Condition

Step 1 – Enter the pass code

Press both the

Target Flame Select

and

Background Flame Select

buttons simultaneously.

Use the up button to drive the LEDs until LED number

[5]

(pass code) is illuminated (if you pass the

required point use the down button to correct).

Press both the

Target Flame Select

and

Background Flame Select

buttons simultaneously.

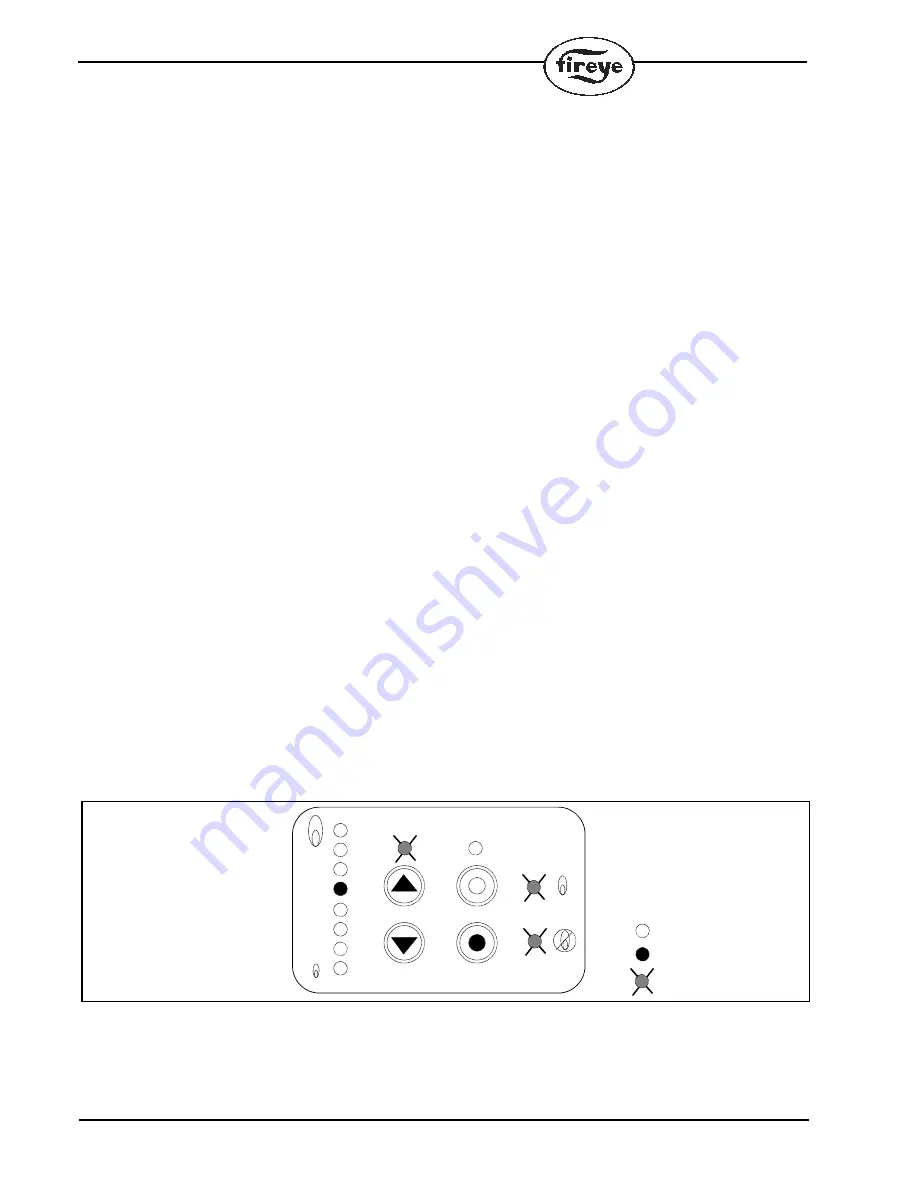

LED indication at this point:

Ready = Flashing

Flame On/Off LED = OFF

Flame Learn LED = Flashing

Background Learn LED = Flashing

PASS CODE ACCEPTED

Step 2 – Learn / Store the Target Flame

Press the Target Flame select button (the Learn Target Flame LED illuminates). Note also that the flame

relay output is energized when the Target Flame Select button is depressed. This is to allow the Phoenix

Scanner to signal flame present to the BMS during commissioning

READY FLAME

= OFF

= ON

= FLASHING