29

!

$

!

#

"

Ø 120 mm - A 941 / AD 941

Ø 140 mm - AD 951

Planer-Thicknesser

A 941 / AD 941 / AD 951

Setup and installation

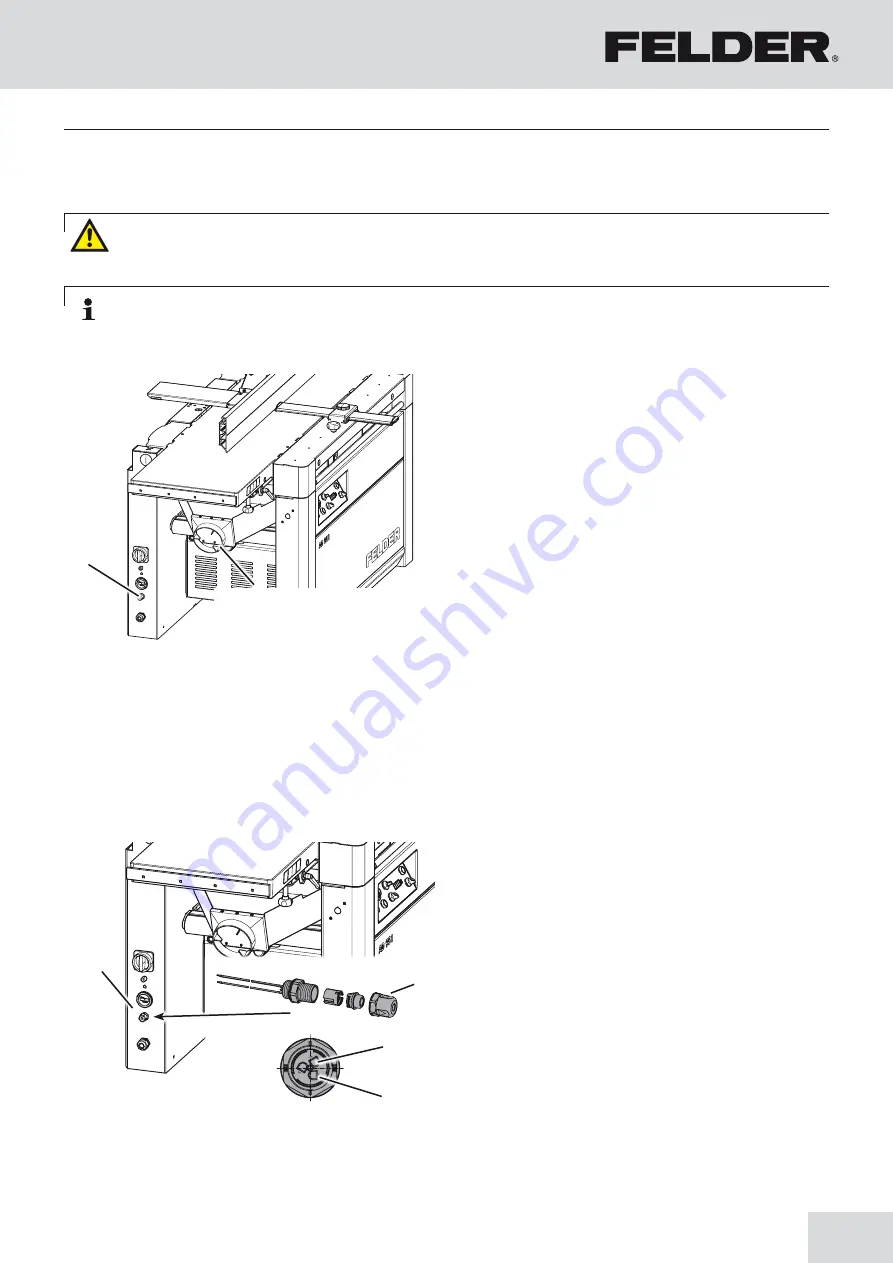

Fig. 7-9: Potential-free contact

Fig. 7-8: Connectors/Dust extraction port dia

7.9 Potential-free contact

7.8 Dust extraction

!

Potential-free contact

Connection to the dust extractor system:

The unit can be connected via the potential-free contact

as follows:

• Cut the wires to the same length.

• Insert into the holes 1 and 2 and push the plugs to-

gether.

• Screw on the plug‘s thumb screw.

• The wires are automatically electrically connected via

an insulation displacement connector.

!

Hole 1

"

Hole 2

#

Thumb screw

$

Potential-free contact

• In addition, the vacuum performance must be sufficient

to achieve the required negative pressures and an air

speed of 20 m/s at the connector. (see “Technical

data”)

• Check the air speed before putting the machine into

operation for the first time and after essential changes.

• The dust extractor setup must be controlled before the

machine is put into operation for the first time. Check for

obvious defects on a daily basis and the efficiency on a

monthly basis.

• The dust extractor must be connected to the machine

in such a manner that it runs in unison with the

machine.

• The dust extraction hoses must be electrically conduc-

tive and grounded to prevent electrostatic

build up.

• Use dust extractors with reduced dust emission to clean

dust from the machine.

Note: As a rule, all units must be vacuumed during use. A time delayed socket is available as an accessory.

Warning! Risk of injury! The dust extraction hose must be non-flammable and must not conduct electricity! For

this reason, only use genuine FELDER dust extraction hoses!

Содержание AD 941

Страница 13: ...13 Planer Thicknesser A 941 AD 941 AD 951 Safety...

Страница 67: ...67 Planer Thicknesser A 941 AD 941 AD 951 Faults...

Страница 69: ...69 Planer Thicknesser A 941 AD 941 AD 951 Annex...

Страница 70: ......

Страница 71: ......