INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 39 of 168

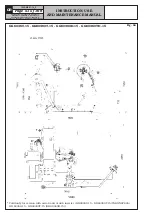

• Place the tool holder arm on the external side then

lower it into “work position” (

Fig. 21 ref. 1

) with

the beading disc facing the wheel. If the outer edge

ring is not sufficiently fitted on the rim, position the

mandrel until the bead wire is near the beading disc.

Move the beading disc forward and then turn the

mandrel until the housing of the O-Ring (if featured)

is uncovered.

• Lubricated the O-Ring and place it in its housing.

• Move to work position

B

(

Fig. 12

).

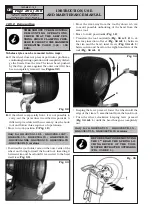

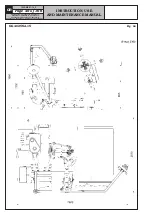

• Position the bead wire (

Fig. 56 ref. 1

) on the rim,

fit the stop ring with the help of the beading disc as

shown in

Fig. 56

.

Fig. 56

• Tilt up tool holder arm placing it in “out of work”

position (

Fig. 22 ref. 1

) after it has been unhooked.

• Lower the mandrel until the wheel rests on the fo-

otboard.

• Close the mandrel jaws completely and translate the

platform outwards until the rim has been completely

removed, making sure the wheel is held up to avoid

dropping.

CLOSING THE MANDREL CAUSES

THE WHEEL TO FALL. ALWAYS

MAKE SURE THAT NO ONE IS

STANDING BY ACCIDENT IN THE

WORK AREA.

13.0 ROUTINE MAINTENANCE

BEFORE CARRYING OUT ANY

ROUTINE MAINTENANCE OR

ADJUSTMENT PROCEDURE, DI-

SCONNECT THE MACHINE FROM

THE ELECTRICITY SUPPLY USING

THE SOCKET/PLUG COMBINATION

AND CHECK THAT ALL MOBILE

PARTS ARE AT A STANDSTILL.

BEFORE EXECUTING ANY MAIN-

TENANCE OPERATION, MAKE

SURE THERE ARE NO WHEELS

LOCKED ONTO THE MANDREL.

BEFORE REMOVING HYDRAULIC

CIRCUIT UNIONS OR PIPES, MAKE

SURE THAT THERE ARE NO PRES-

SURISED FLUIDS PRESENT. PRES-

SURISED OIL SPILLS MAY CAUSE

SERIOUS WOUNDS OR INJURIES.

BEFORE CARRYING OUT ANY

MAINTENANCE WORK ON THE

HYDRAULIC CIRCUIT, SET THE

MACHINE IN THE REST CONDI-

TION.

To guarantee the efficiency and correct functioning of

the machine, it is essential to carry out daily or weekly

cleaning and weekly routine maintenance, as described

below

Cleaning and routine maintenance must be conducted

by authorized personnel and according to the instruc-

tions given below.

• Disconnect the mains power supply before starting

any cleaning or routine maintenance operations.

• Remove deposits of tyre powder and other waste

materials with a vacuum cleaner.

• DO NOT BLOW IT WITH COMPRESSED AIR.

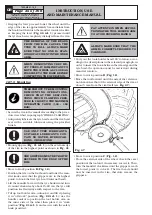

• Periodically (preferably once a month) make a com-

plete check on the controls, ensuring that they pro-

vide the specified actions.

• Every 100 working hours lubricate the (tool and

mandrel) carriage sliding guides.

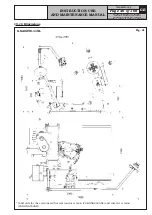

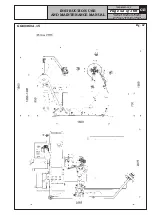

• Periodically (preferably once a month), grease all

moving parts of the machine (see

Fig. 57

).

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15