INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 14 of 168

2.1

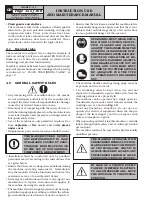

Training of personnel

The machine may be operated only by suitably

trained and authorized personnel.

Given the complexity of the operations necessary to ma-

nage the machine and to carry out the operations safely

and efficiently, the personnel must be trained in such

a way that they learn all the information necessary to

operate the machine as intended by the manufacturer.

A CAREFUL READING OF THIS

INSTRUCTION MANUAL FOR USE

AND MAINTENANCE AND A SHORT

PERIOD OF TRAINING WITH SKIL-

LED PERSONNEL CAN BE AN

ENOUGH PREVENTIVE PREPARA-

TION.

3.0 SAFETY DEVICES

PERIODICALLY, AT LEAST MONTH-

LY, CHECK THE INTEGRITY AND

THE FUNCTIONALITY OF THE

SAFETY AND PROTECTION DE-

VICES ON THE MACHINE.

All the machines are equipped with:

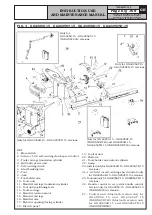

• “man-operated” controls (immediate stop of opera-

tion when the control is released).

• Controls logic disposition

To prevent the operator from making dangerous

mistakes.

• thermal magnetic switch on the supply line of the

oil-pressure power unit motor: avoids the motor

overheating in case of intensive use.

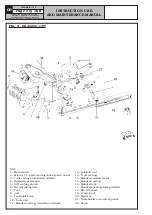

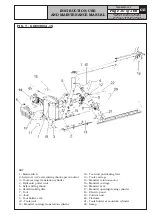

Fig. 9

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

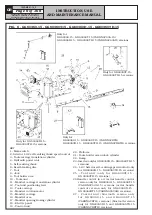

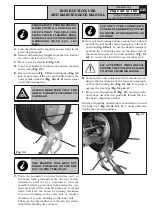

NO MODIFICATION OR CALIBRA-

TION OF THE OPERATING PRES-

SURE OF THE MAXIMUM PRESSU-

RE VALVE OR OF THE HYDRAULIC

CIRCUIT PRESSURE LIMITER IS

PERMITTED

• controlled check valves on:

- opening of clamping unit jaws,

- mandrel arm lifting,

- tool holder arm tilting (only for versions foreseeing

such operation).

These valves have been fit in order to avoid unex-

pected movements of the jaws, tool or mandrel arm

(and, as a consequence, the wheel fall) caused by

accidental oil drippings.

• Fuses on the electric supply line of the clamping

unit motor,

• Automatic power supply disconnection with the

opening of the electric panel.

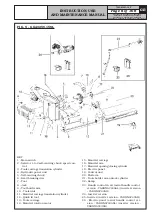

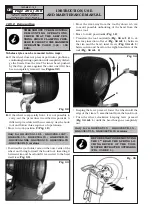

• Mandrel self-braking motor (only for GG40256.15,

GG40256T.15, GG40256A.15, GG40256D.15,

GG40256TD.15, GG60360.15, GG60360T.15,

GG60360A.15, GG60360D.15 and GG60360TD.15).

• Mandrel self-braking motor (on demand only

f o r G G 4 0 2 5 6 . 1 1 S L , G G 4 0 2 5 6 . 1 1 S T a n d

GG40256.15SL).

•

Motor protection devices

(only for GG40256D.15,

GG40256TD.15, GG60360D.15 and GG60360TD.15)

The new “Invemotor” unit is equipped with electronic

protection devices. They stop the motor if working

defected conditions appear to avoid that the motor

itself can be damaged and that the operator safety

can be compromised (overvoltage, undervoltage,

overload, overtemperature).

For more details, see Chapt. 14 “Troubleshooting

table”.