INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 2 of 168

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

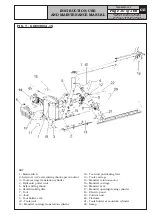

SUMMARY

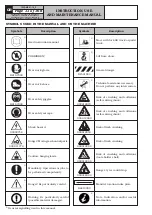

SYMBOLS USED IN THE MANUAL AND

ON THE MACHINE _______________________ 11

1.0 GENERAL INTRODUCTION _________ 13

1.1 Introduction ___________________________13

2.0 INTENDED USE ____________________ 13

2.1 Training of personnel _________________14

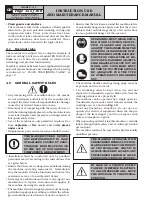

3.0 SAFETY DEVICES __________________ 14

3.1 Residual risks _________________________15

4.0 GENERAL SAFETY RULES _________ 15

5.0 PACKING AND MOBILIZATION FOR

TRANSPORT _______________________ 16

6.0 UNPACKING ________________________ 16

7.0 MOBILIZATION _____________________ 16

8.0 WORKING ENVIRONMENT CONDI-

TIONS ______________________________ 17

8.1 Working position ______________________17

8.2 Installation space _____________________17

8.3 Lighting _______________________________17

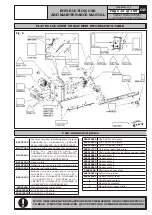

9.0 MACHINE ASSEMBLY ______________ 17

9.1 Anchoring system _____________________17

9.2 Fixtures contained in the packing _____18

10.0 ELECTRICAL CONNECTIONS _______ 18

10.1 Oil check on oil-pressure power unit __18

10.2 Check of motor rotation direction _____19

10.3 Electrical checks ______________________19

11.0 CONTROLS _________________________ 20

11.1 Cable control device ___________________20

11.2 Control device with bluetooth

transmission (optional) _______________21

11.3 Handle control in air (standard for

GG40256A.15 - GG60360A.15 ver-

sions) (optional for GG40256.11SL

(VARGNAV43AD - VARGNAV43ASL)

- GG40256.15SL (VARGNAV43AD

- VARGNAV43ASL) - GG40256.15

and GG40256T.15 (VARGNAV43A) -

GG60360.15 and GG60360T.15

(VARGNAV63A.15) - GG60360D.15 and

GG60360TD.15 (VARGNAV63AD)) ______22

12.0 USING THE MACHINE ______________ 23

12.1 Precaution measures during tyre re-

moval and fitting ______________________23

12.2 Preliminary operations ________________23

12.3 Preparing the wheel ___________________23

12.4 Wheel clamping _______________________23

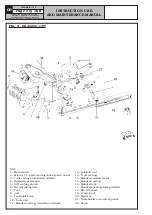

12.5 Functioning of tool holder arm ________25

12.5.1 Tools rotation ______________________26

12.5.2 Tools unit extraction/insertion _____26

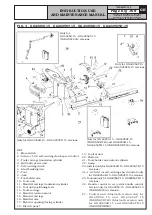

12.5.3 Quick-fit device (GG40256.11SL,

GG40256.11ST and

GG40256.15SL) ____________________26

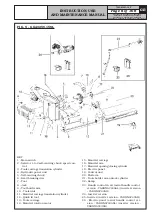

12.6 Tubeless tyres _________________________27

12.6.1 Bead breaking _____________________27

12.6.2 Demounting ________________________29

12.6.3 Mounting ___________________________31

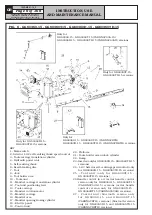

12.7 Tyres with inner tube _________________33

12.7.1 Bead breaking _____________________33

12.7.2 Demounting ________________________34

12.7.3 Mounting ___________________________35

12.8 Wheels with bead wire ________________37

12.8.1 Beading and demounting __________37

12.8.2 Mounting ___________________________38

13.0 ROUTINE MAINTENANCE __________ 39

14.0 TROUBLESHOOTING TABLE _______ 42

15.0 TECHNICAL DATA __________________ 44

15.1 GG40256.11SL technical data ________44

15.2 GG40256.11ST technical data ________44

15.3 Technical data GG40256.15 -

GG40256T.15 __________________________44

15.4 GG40256A.15 technical data __________44

15.5 Technical data GG40256D.15 -

GG40256TD.15 ________________________44

15.6 GG40256.15SL technical data ________45

15.7 Technical data GG60360.15 -

GG60360T.15 __________________________45

15.8 GG60360A.15 technical data __________45

15.9 Technical data GG60360D.15 -

GG60360TD.15 ________________________45

15.10 Dimensions ___________________________46

16.0 STORING ___________________________ 53

17.0 SCRAPPING ________________________ 53

18.0 REGISTRATION PLATE DATA ______ 53

19.0 FUNCTIONAL DIAGRAMS __________ 53

Table A - Electric diagram

(GG40256.11SL - GG40256.15SL) _54

Table B - Electric diagram

(GG40256.11ST) __________________63

Table C - Electric diagram

(GG40256.15 - GG40256T.15 -

GG60360.15 - GG60360T.15) _____72