INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 21 of 168

7522-M001-14_P

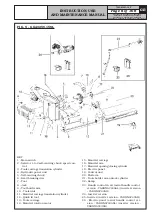

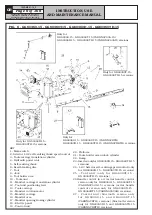

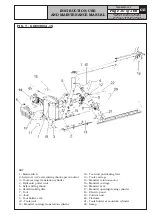

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

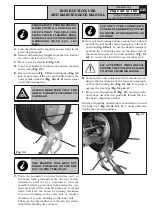

11.2 Control device with bluetooth transmis-

sion (optional)

The control (handle control) can be moved according

to the positioning necessities of the operator.

The operator should place the control in a zone free

from obstacles in order to see clearly and completely

the operative zone.

MAKE SURE THERE ARE NO PER-

SONS OR OBJECTS HIDDEN TO

THE OPERATOR VISUAL FIELD

BY THE WHEEL SIDE PLAY (ESPE-

CIALLY IN CASE OF WHEELS WITH

LARGE DIMENSIONS).

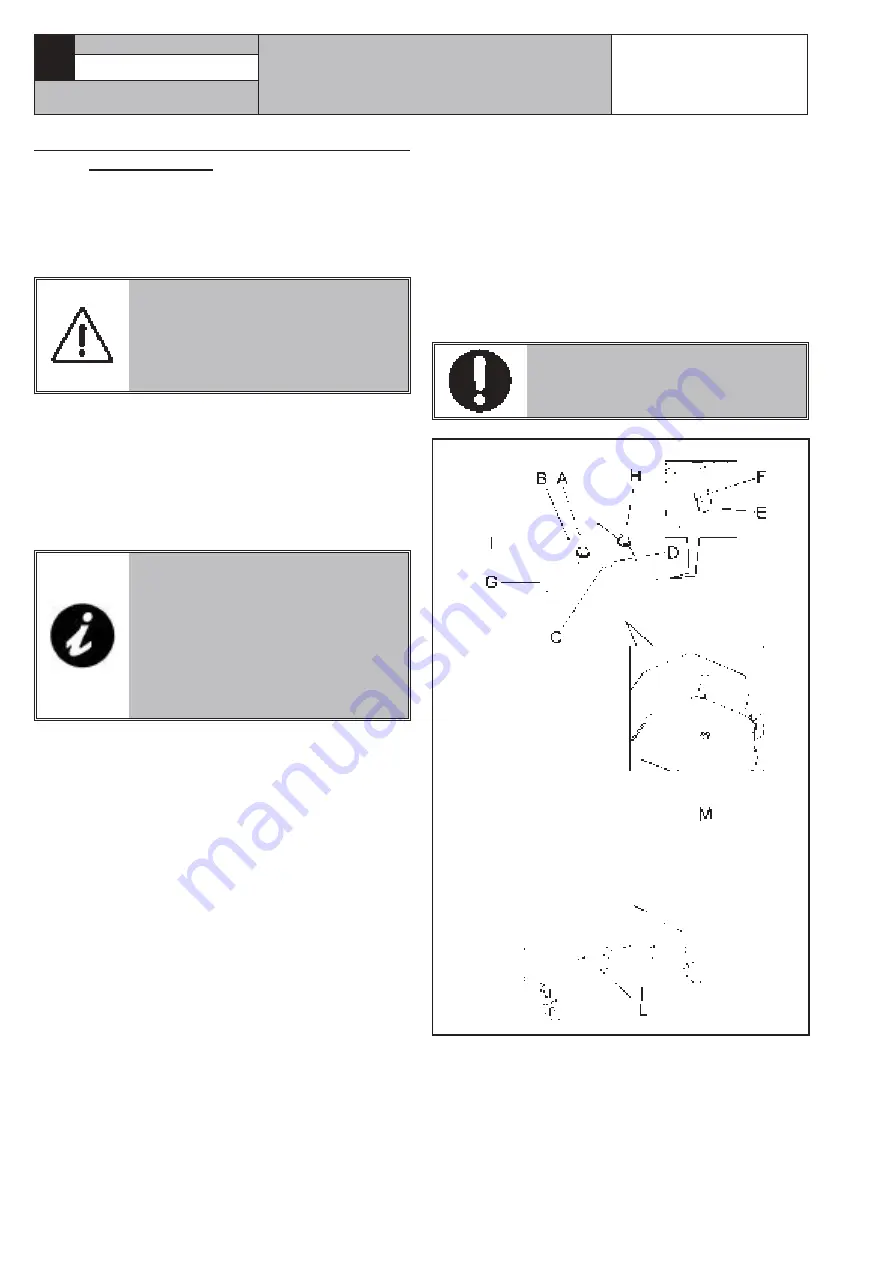

The flashing green led “

A

”, indicates the machine

stand-by position. When any control is operated, the

machine is started and it is ready for operation. During

functioning, the led “

A

” is turned on with a fixed light.

The red turned on led “

B

” and the green turned off

led “

A

” indicate that the manipulator batteries are

exhausted: in order to carry on the functioning, the

batteries must be charged.

IN ORDER TO ACTIVATE THE COM-

MUNICATION BETWEEN HANDLE

CONTROL AND MACHINE, ON MA-

CHINE SWITCHING AND AFTER

EACH POSITIONING IN STAND-BY

MODE, IT'S NECESSARY TO OPE-

RATE ANY JOYSTICK (LEVER “H”

OR LEVER “I”) FOR 5 SECONDS

AT LEAST.

“Push button

C

” has a maintained control position, and

when pressed it rotates the tool holder head counter-

clockwise (from behind the tool).

“Push button

D

” has a maintained control position, and

when pressed it rotates the tool holder head clockwise

(from behind the tool).

“Push-button

E

” has a maintained control position,

and when pressed, it operates the self-centring chuck

opening.

“Push-button

F

” has a maintained control position,

and when pressed it operates the self-centring chuck

closing.

“Button

G

” has one “hands-on” operating position:

when it is pressed and lever “

I

” or “

H

” is laterally

shifted at the same time, it doubles the translation

speed of the self-centring carriage and of the tool holder

carriage respectively.

“Lever

H

” has four maintained control positions:

- Lever rightwards or leftwards, operates respectively

the tool holder carriage shifting rightwards or lef-

twards.

- Lever upwards or downwards: it respectively lowers

or lifts the tool holder arm.

“Lever

I

” has four maintained control positions:

- Lever rightwards or leftwards, operates respectively

the mandrel holder carriage shifting rightwards or

leftwards.

- Lever upwards or downwards: it operates respectively

the rising and the lowering of the mandrel holding

arm.

“Pedal

L

” starts clockwise and anti-clockwise rotation

of the mandrel.

When any control is operated, the machine is started

again, ready for operation: led “

A

” flashes.

THE HANDLE MUST NOT BE PLA-

CED WHERE WATER STAGNATES.

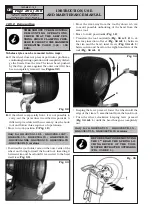

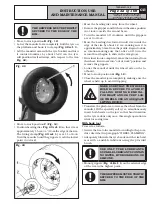

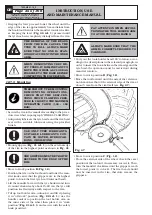

Fig. 16