INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 13 of 168

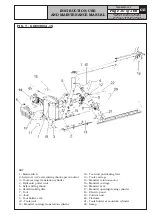

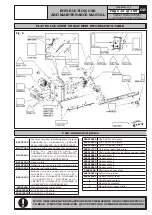

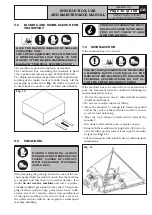

NOTE: SOME OF THE PICTURES

PRESENT IN THIS MANUAL HAVE

BEEN OBTAINED FROM PICTURES

OF PROTOTYPES, THEREFORE

THE STANDARD PRODUCTION

MACHINES AND ACCESSORIES

CAN BE DIFFERENT IN SOME

COMPONENTS.

1.0 GENERAL INTRODUCTION

This manual is an integral part of the product and

must be retained for the whole operating life of the

machine.

Carefully study the warnings and instructions contai-

ned in this manual. It contains important instructions

regarding

FUNCTIONING, SAFE USE and MAINTE-

NANCE.

KEEP THE MANUAL IN A KNOWN,

EASILY ACCESSIBLE PLACE FOR

ALL ACCESSORY OPERATORS

TO CONSULT IT WHENEVER IN

DOUBT.

THE MANUFACTURER DISCLAIMS

ALL RESPONSIBILITY FOR ANY

DAMAGE OCCURRED WHEN THE

INDICATIONS GIVEN IN THIS MA-

NUAL ARE NOT RESPECTED: AS

A MATTER OF FACT, THE NON-

COMPLIANCE WITH SUCH INDI-

CATIONS MIGHT LEAD TO EVEN

SERIOUS DANGERS.

1.1 Introduction

Thank you for preferring this electro-hydraulic tyre

changer. We feel sure you will not regret your decision.

This machine has been designed for use in profes-

sional workshops and in particular it stands out for

its reliability and easy, safe and rapid operation: with

just a small degree of maintenance and care, this tyre

changer will give you many years of trouble-free service

and lots of satisfaction.

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

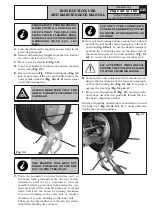

2.0 INTENDED USE

The electrohydraulic functioning tyre changing ma-

chines model

“GG40256.11SL, GG40256.11ST,

GG40256.15, GG40256T.15, GG40256A.15,

GG40256D.15, GG40256TD.15, GG40256.15SL,

GG60360.15, GG60360T.15, GG60360A.15,

GG60360D.15, GG60360TD.15”

with relevant

versions, must be used only for the assembly and

disassembly of any type of whole (grooved and

with bead wire) rim wheel, with the maximum

dimensions of 2360 mm/93” (

GG40256.11SL,

GG40256.11ST, GG40256.15, GG40256T.15,

GG40256A.15, GG40256D.15, GG40256TD.15

a n d G G 4 0 2 5 6 . 1 5 S L

) - 2 7 0 0 m m / 1 0 6 ”

(

GG60360.15, GG60360T.15, GG60360A.15,

GG60360D.15 and GG60360TD.15

) and ma-

ximum weight of 2000 Kg (

GG40256.11SL,

GG40256.11ST, GG40256A.15, GG40256D.15

and GG40256TD.15

) - 2300 Kg (

GG40256.15,

GG40256T.15, GG40256.15SL, GG60360A.15,

GG60360D.15 and GG60360TD.15

) - 2600 Kg

(

GG60360.15 and GG60360T.15

).

T h e m a c h i n e s m o d e l

“ G G 4 0 2 5 6 . 1 1 S L ,

GG40256.11ST, GG40256.15, GG40256T.15,

GG40256A.15, GG40256D.15, GG40256TD.15,

GG40256.15SL, GG60360.15, GG60360T.15,

GG60360A.15, GG60360D.15, GG60360TD.15”

with relevant versions, MUST NOT be used for tyre

inflation.

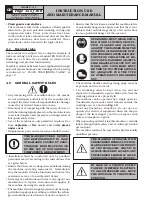

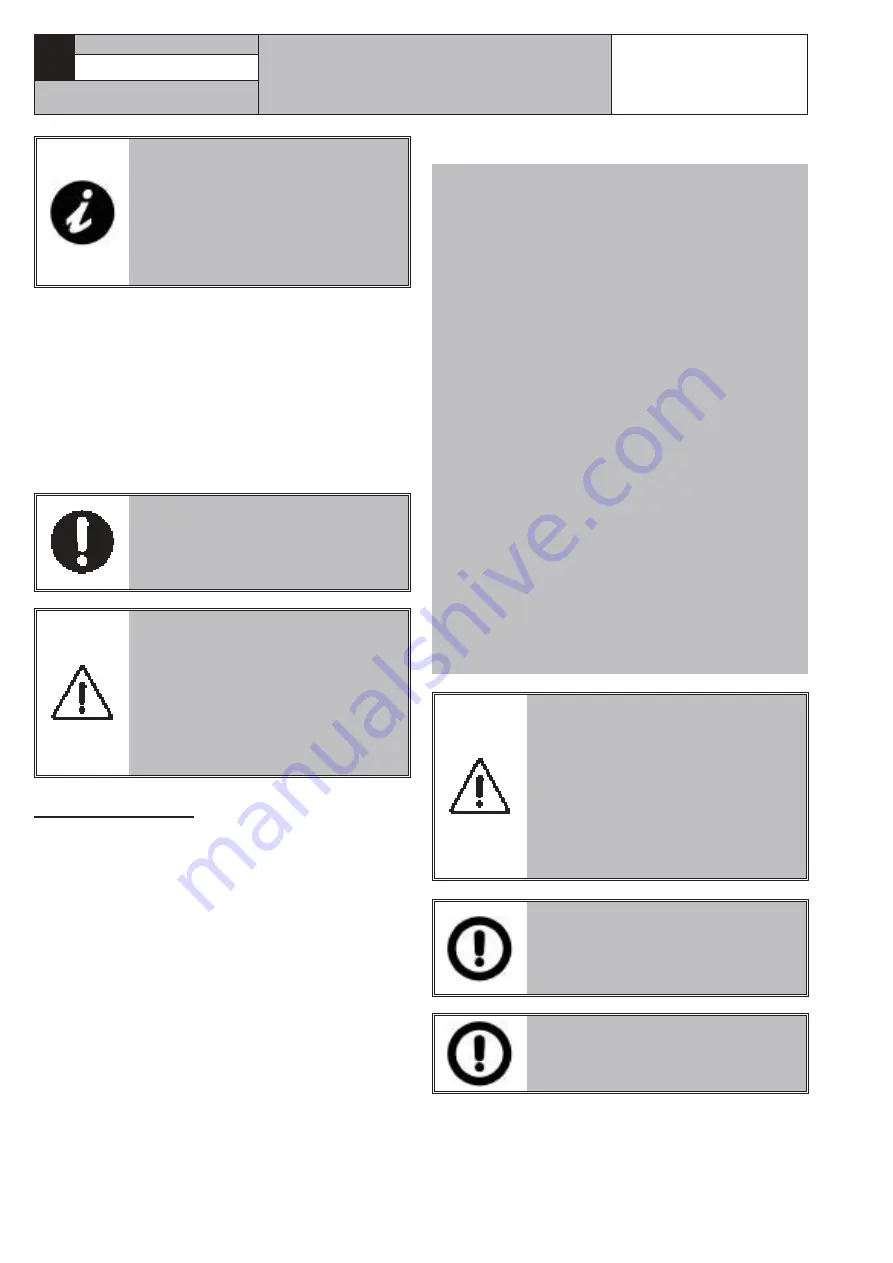

THIS MACHINE MUST BE USED

STRICTLY FOR THE INTENDED

PURPOSE IT WAS DESIGNED

FOR (AS INDICATED IN THIS MA-

NUAL). ANY OTHER USE WILL BE

CONSIDERED IMPROPER USE. IN

PARTICULAR BEAD FITTING AND

INFLATING MUST BE CARRIED

OUT IN A SPECIALLY APPROVED

INFLATION CAGE.

THE MANUFACTURER CANNOT

BE HELD RESPONSIBLE FOR ANY

DAMAGE CAUSED BY IMPROPER,

ERRONEOUS, OR UNACCEPTABLE

USE.

AN INTENSIVE USE OF THE

EQUIPMENT IN INDUSTRIAL EN-

VIRONMENT IS NOT RECOMMEN-

DED.