INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 17 of 168

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

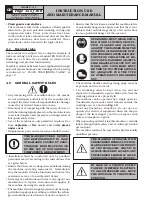

8.0 WORKING ENVIRONMENT CONDI-

TIONS

The machine must be operated under proper condi-

tions as follows:

• temperature: 0° + 55° C

• relative humidity 30 - 95% (dew-free)

• atmospheric pressure: 860 - 1060 hPa (mbar).

The use of the machine in ambient conditions other

than those specified above is only allowed after prior

agreement with and approval of the manufacturer.

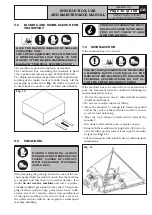

8.1

Working position

In

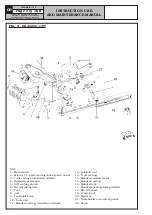

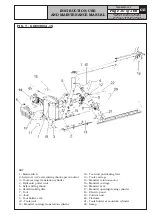

Fig. 12

it's possible to define working positions

A,

B, C, D

which will be referred to in the description of

machine operative phases.

Positions

A

and

B

must be considered as main posi-

tions for tyre mounting and demounting and for wheel

clamping on the mandrel, while positions

C

and

D

are

the best positions to follow tyre bead breaking and

demounting operations.

Working in these positions allows better precision and

speed during operating phases as well as greater safety

for the operator.

8.2

Installation space

A

B

C

D

Fig. 12

INSTALL THE MACHINE INDOORS OR IN A RO-

OFED AREA. PLACE OF INSTALLATION MUST

BE DRY, ADEQUATELY LIT AND IN COMPLIAN-

CE WITH APPLICABLE SAFETY REGULATIONS.

The location of the machine requires a usable space of

5800x4500 mm, (as indicated in

Fig. 12

). The positio-

ning of the machine must be according to the distances

shown. From the control position the operator is able

to observe all the machine and surrounding area. He

must prevent unauthorized personnel or objects that

could be dangerous from entering the area.

The machine must be fixed on a flat floor surface, pre-

ferably of cement or tiled. Avoid yielding or irregular

surfaces.

The base floor must be able to support the loads

transmitted during operation. This surface must have

a capacity load of at least 500 kg/m².

The depth of the solid floor must be sufficient to gua-

rantee that the anchoring bolts hold.

8.3 Lighting

The machine does not require its own lighting for nor-

mal working operations. However, it must be placed

in an adequately lit environment.

For correct lighting, use lamps having total power

800/1200 Watt as envisaged by UNI 10380.

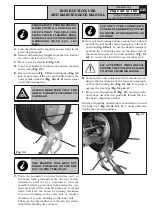

9.0 MACHINE ASSEMBLY

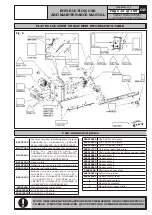

9.1

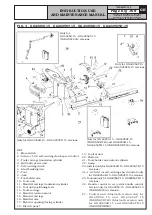

Anchoring system

The packed machine is fixed to the pallet through the

holes prearranged on the frame. Such holes also fix the

machine to the ground through anchor small blocks

as shown in

Fig. 13

.

Fig. 13

GG40256.11SL

GG40256.11ST

GG40256.15

GG40256T.15

GG40256A.15

GG40256D.15

GG40256TD.15

GG40256.15SL

GG60360.15

GG60360T.15

GG60360A.15

GG60360D.15

GG60360TD.15

a

= 1185 mm

b

= 1840 mm

a

= 1185 mm

b

= 2173 mm

a

= 1216 mm

b

= 2265 mm

• Execute four holes with 12 mm diameter on the floor

by the holes on the bottom floor;

• introduce the small blocks in the holes;

• fix the machine to the ground with four M12x120

mm screws (or four 12x80 mm stud bolts). Tighten

the screws with an approximate tightening torque

of 70 Nm.