INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 38 of 168

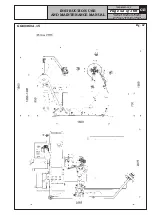

• Carry out the tools holder head 180° rotation accor-

ding to the description of the relevant paragraph, in

order to let the beading disc come into contact with

the tyre outer side (see

Fig. 54

).

Fig. 54

• Turn the mandrel and smear the entire bead seat of

the rim with lubricant.

• While doing this, jerk the beading disc forward until

the first bead is removed;

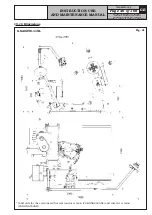

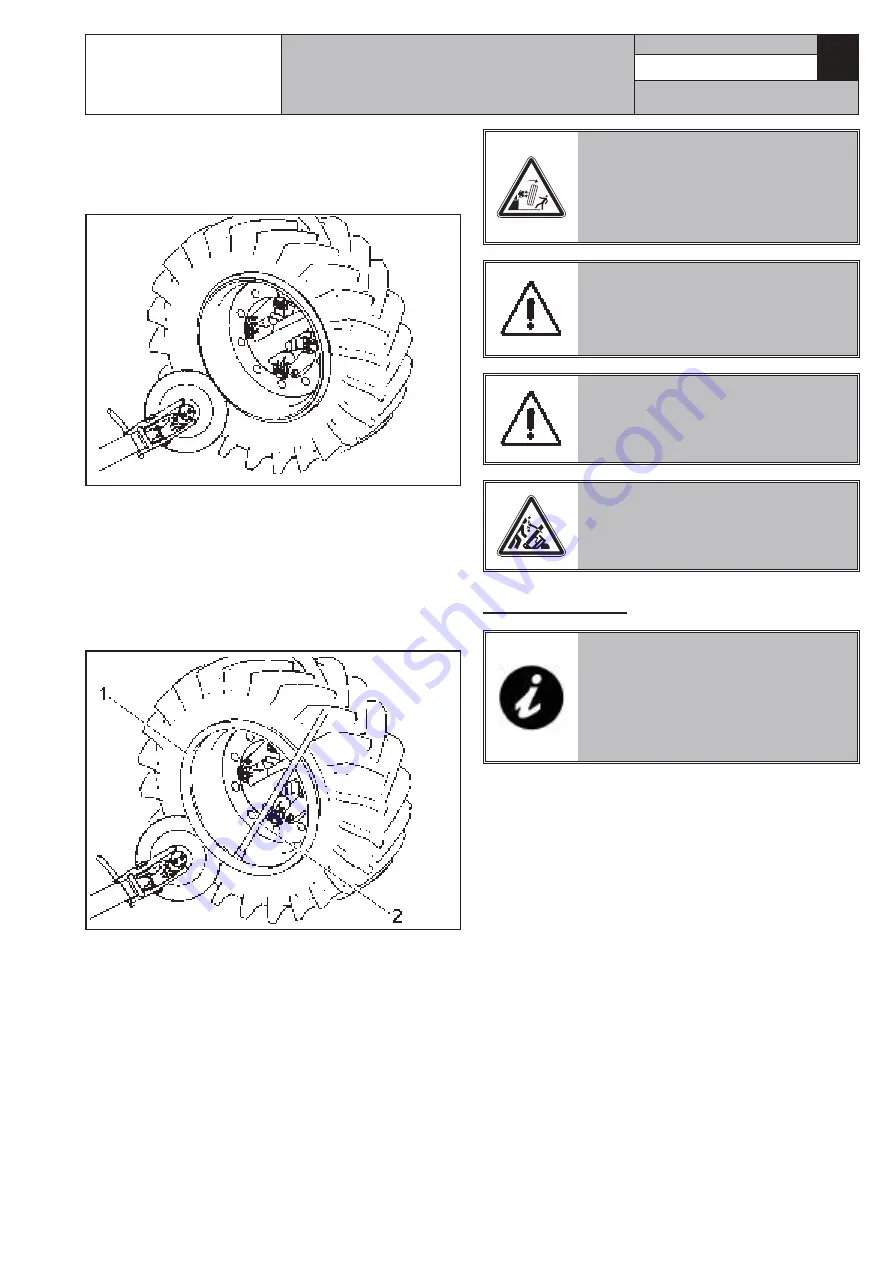

• Repeat the operation, making the beading disc move

forward (see

Fig. 55

) until the stop ring is released

(

Fig. 55 ref. 1

). It will be then extracted through

lever (

Fig. 55 ref. 2

).

Fig. 55

• Remove the bead wire.

• Remove the O-Ring, when featured.

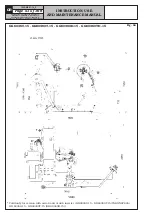

• Tilt up tool holder arm placing it in “out of work”

position (

Fig. 22 ref. 1

) after it has been unhooked.

• Lower the mandrel until the wheel rests on the fo-

otboard.

• Move to work position

B

(

Fig. 12

).

• Move backward the mandrel until the tyre is com-

pletely dislodged from the rim (in case of tyres with

inner tube, make sure that the valve hasn’t been

damaged during removal).

THE REMOVAL OF THE BEADS

FROM THE RIM CAUSES THE

TYRE TO FALL. ALWAYS MAKE

SURE THAT NO ONE IS STAN-

DING BY ACCIDENT IN THE WORK

AREA.

WHEN DEMOUNTING VERY HE-

AVY TYRES, IT IS IMPORTANT TO

MOVE THE WHEEL AS CLOSE AS

POSSIBLE TO THE BASE BEFORE

COMPLETING THE OPERATION.

PAY ATTENTION WHEN REPOSI-

TIONING THE TOOL HOLDER ARM

TO AVOID CRUSHING HANDS.

ALWAYS MAKE SURE THAT THE

ARM IS CORRECTLY HOOKED TO

CARRIAGE.

12.8.2 Mounting

THROUGHOUT TYRE MOUNTING/

DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CEN-

TRING CHUCK CLAMPING PRES-

SURE IS CLOSE TO THE MAXIMUM

OPERATING VALUE (160 - 180

BAR).

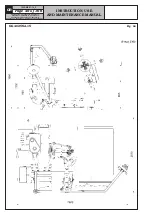

• Place the tools holder arm in “off-work position”

(

Fig. 22 ref. 1

); if it has been removed, fix the rim

to the mandrel as described in “WHEEL CLAMPING”

paragraph. If the wheel features an inner tube, po-

sition the rim with the valve slot facing downwards

(at 6 o’clock).

• Lubricate the entire bead seat of the rim and the

tyre beads.

• Move to work position

B

(

Fig. 12

).

• Place the mandrel in order to centre the rim on the

tyre.

• Operate the mandrel forward translation in order to

insert the rim in the tyre (in case of air tube tyres,

make the valve re-enter not to damage it). Move

forward until the rim is completely inserted in the

tyre.

• Insert the bead wire on the rim with the stop ring

fitted (if the rim and bead wire feature fixing slits,

they must be in phase with each other).

• Move to work position

C

(

Fig. 12

).

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15