February 2017

www.farmscanag.com

AM-74V1-4

12

Installation (Sensors)

INSTALLATION (SENSORS)

WHEEL SENSOR FOR GROUND SPEED

(Farmscan Ag Part # 1007P Kit)

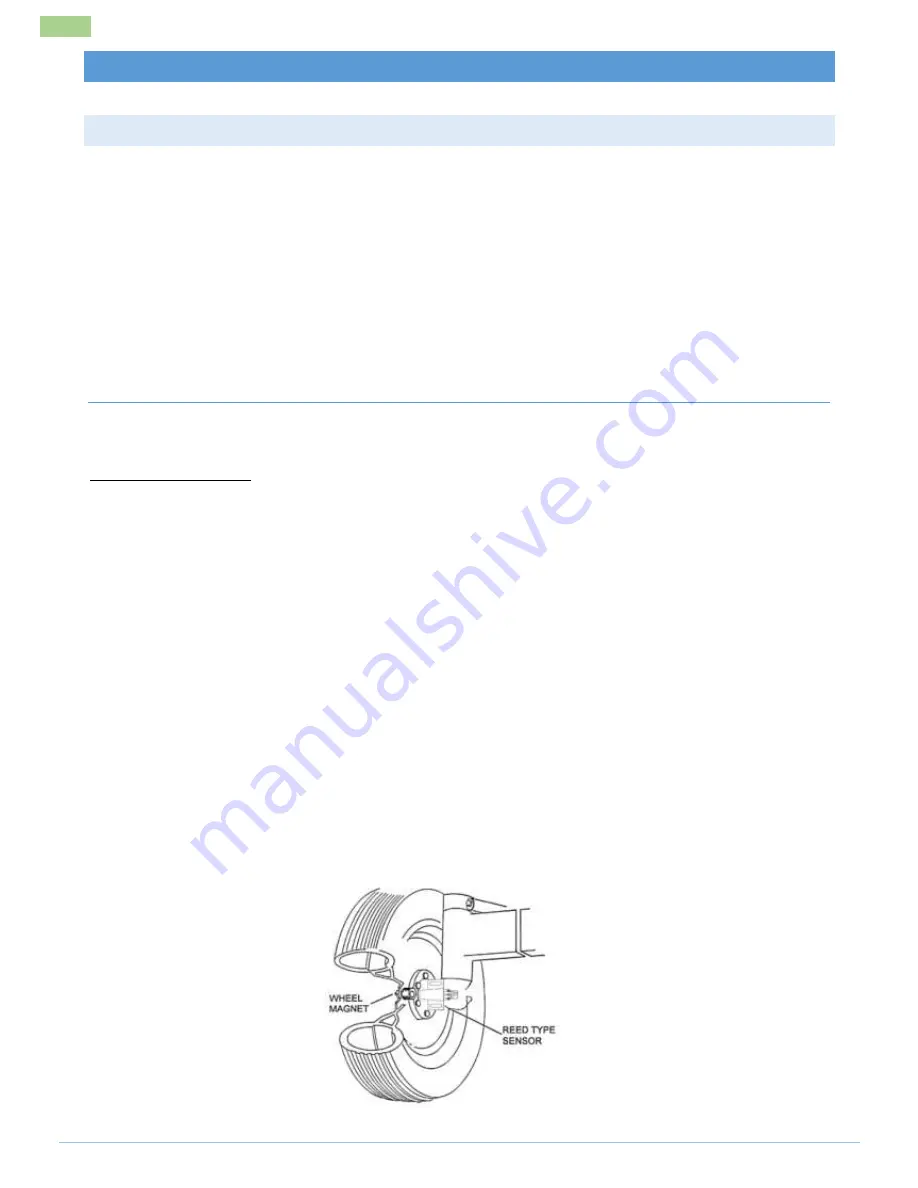

The wheel sensor consists of a reed-type sensor (magnetic switch) and wheel magnet to be fitted onto any

non-driven ground wheel of the sprayer. The magnet activates the sensor as it sweeps past.

The spray controller requires at least one wheel pulse per second from the sensor.

NOTES:

In circumstances where an extremely large wheel is working at slow speeds (less than 5kph),

additional wheel magnets may be fitted at equal spacing’s.

Any sprayers that do not have a non-driven ground wheel can use a GPS speed sensor as an

alternative.

WHEEL SENSOR INSTALLATION PROCEDURE

To install wheel sensor:

1.

Bolt the wheel magnet onto the inside of the wheel in a position that allows the magnet to sweep

directly past the wheel sensor within a 5 - 10 mm clearance. Maximum clearance is 15 mm. The bolt

in the magnet can be replaced with a longer or shorter bolt as required.

2.

The magnet can be mounted anywhere in a radius from the centre of the wheel. Nearer to the hub

will ensure the best ground clearance.

3.

The sensor must be rigidly bolted to an existing structure, ideally in a protected position to face the

magnet as shown in the diagram below.

4.

If the sensor is mounted on a steered wheel, make sure the sensor moves with the steering

mechanism to maintain constant clearance between the magnet and the sensor when turning from

lock to lock.

5.

A 5m-extension cable can be purchased to connect the sensor to the sprayer loom connector

marked ‘wheel’. (Farmscan Ag Part # AC-205/5m or AC-210/10m)

6.

Use cable ties to secure sensor cable away from risk of damage or chaffing.