Maintenance 6. Arm #2

G6 Rev.21

137

Joint #2

reduction gear

unit

Installation

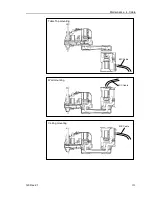

(1) A new reduction gear unit contains the parts

shown in the picture on the right when it is

unpacked.

Apply grease (SK-1A) to the waveform

generator and flexspline so that the gear surface

is filled with grease.

(2) Set the hole on the circular spline and the tap

hole on the base.

Loosely secure all bolts in a crisscross pattern so

that the bolts will be secured evenly. Then, using

a torque wrench, tighten each bolt securely in a

crisscross pattern at the torque specified in the

table below.

16-M3

×

15

Circular spline

Item

Bolt type

Number of bolts

Tightening torque

Joint #2 reduction gear unit

M3

×

15

16

3.0 N

⋅

m (30.5 kgf

⋅

cm)

M5

×

15

8

12.0 N

⋅

m (122.3 kgf

⋅

cm)

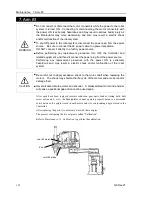

(3) Set the grip ring by aligning it with the tap hole.

Set the flexspline by aligning it with the tap hole.

Align the tap hole and mount the flexspline.

Align the position of the air vent of the spacer.

If it is difficult to align the position, move Arm

#2 from side to side.

8-M5

×

15

Flexspline

Spacer

Grip ring

(4) Apply grease (SK-1A) inside the flexspline.

Grease volume 15 g

(5) Apply grease (SK-1A) to the bearing part of the waveform generator.

(6) Execute steps from (2) to (9) in Maintenance: 6.1 Replacing Joint #2 Motor.

Содержание G6 series

Страница 1: ...Rev 21 EM183R3621F SCARA ROBOT G6 series MANIPULATOR MANUAL ...

Страница 2: ...MANIPULATOR MANUAL G6 series Rev 21 ...

Страница 8: ...vi G6 Rev 21 ...

Страница 14: ......

Страница 93: ...Maintenance This volume contains maintenance procedures with safety precautions for G6 series Manipulators ...

Страница 94: ......

Страница 120: ...Maintenance 4 Cable 108 G6 Rev 21 Table Top mounting Cable Unit Wall mounting Cable Unit Ceiling mounting Cable Unit ...

Страница 135: ...Maintenance 4 Cable G6 Rev 21 123 Table Top mounting M C Cable Wall mounting M C Cable Ceiling mounting M C Cable ...

Страница 216: ...Maintenance 14 Maintenance Parts List 204 G6 Rev 21 ...