ENVIRO-TEC

3

FORM ET115.24-NOM4 (819)

CHANGEABILITY OF THIS DOCUMENT

In complying with ENVIRO-TEC's policy for continu-

ous product improvement, the information contained

in this document is subject to change without notice.

ENVIRO-TEC makes no commitment to update or

provide current information automatically to the man-

ual or product owner. Updated manuals, if applicable,

can be obtained by contacting the nearest ENVIRO-

TEC Service office.

It is the responsibility of rigging, lifting, and operating/

service personnel to verify the applicability of these

documents to the equipment. If there is any question

regarding the applicability of these documents, rig-

ging, lifting, and operating/service personnel should

verify whether the equipment has been modified and

if current literature is available from the owner of the

equipment prior to performing any work on the chiller.

CHANGE BARS

Revisions made to this document are indicated with a

line along the left or right hand column in the area the

revision was made. These revisions are to technical in-

formation and any other changes in spelling, grammar

or formatting are not included.

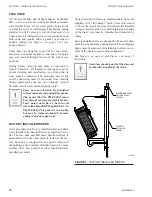

The equipment covered by this manual is designed for

safe and reliable operation when installed, operated,

and maintained within its’ design specifications. To

avoid personal injury or damage to equipment or prop-

erty during installation, operation, and maintenance of

this equipment, it is essential that these functions be

performed by qualified, experienced personnel using

good judgment and safe practices. See the following

cautionary statements.

ELECTRICAL SHOCK HAZARDS. All

power must be disconnected prior to in-

stallation and servicing of this equipment.

More than one power source may be pres-

ent. Disconnect all power sources to avoid

electrocution or shock injuries.

MOVING PARTS HAZARDS. Power

must be disconnected from the motor and

blower prior to opening access panels.

Motors can start automatically, and more

than one power source may be present.

Disconnect all power and control circuits

prior to servicing to avoid serious crush-

ing or dismembering injuries.

Electric resistance heating elements

may start automatically. Disconnect all

power and control circuits, and allow

the elements to cool before servicing.

Again, more than one power source may

be present.

HOT PARTS HAZARDS. Hot water and

steam heating coils operate at tempera-

tures that will cause severe burn injury.

Some systems will continue to allow cir-

culation of hot water, even with all control

circuits deenergized. Before performing

service at or near any heating coil, piping,

or valve package component, disconnect

all power and close all isolation valves,

and allow the equipment to cool. As pre-

viously mentioned, more than one power

source may be present.

Check that the unit assembly and compo-

nent weights can be safely supported by

rigging and lifting equipment.

All assemblies must be adequately se-

cured during lifting and rigging by

temporary supports and restraints until

equipment is permanently fastened and

set in its final location.

All unit temporary and permanent sup-

ports must be capable of safely sup-

porting the equipment’s weight and any

additional live or dead loads that may

be encountered. All supports must be

designed to meet applicable local codes

and ordinances.

SAFETY CONSIDERATIONS

Содержание VHA

Страница 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 22: ...ENVIRO TEC 22 FORM ET115 24 NOM4 819 SECTION 1 RECEIPT INSTALLATION THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

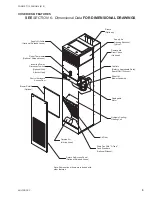

Страница 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Страница 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...