ENVIRO-TEC

27

SECTION 2 - START-UP

FORM ET115.24-NOM4 (819)

2

The PWM board times out in Program

Mode after approximately 5-6 minutes

and will need to be reset by pushing the

reset button. If more time is needed to

verify correct airflow, perform the STORE

operation (through switch 8) after adjust-

ment to save the adjusted fan speed.

6. Determine desired fan operating points. Refer to

the Fan Calibration Curve label supplied on the

side of the equipment. There are two different

styles of Fan Calibration Curve, depending on EC

motor type.

The Fan Calibration Curve provided with

the unit represents response for a unit

with typical configuration. Actual airflow

may vary slightly depending on actual

system configuration.

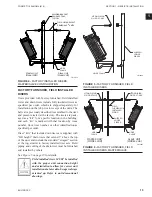

a. Constant RPM EC Motor. Refer to

Figure 14

on page 27

for sample label. Five curves

are shown, showing factory default airflow

for Minimum, Low, Medium, High, and

Maximum speeds. A table is provided which

shows the expected voltage across test points

TP1 and TP3 for each speed, depending on

whether the unit is set up for three speed or

2 – 10 VDC motor control.

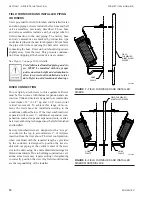

b. b. Constant Airflow or Constant Torque EC

Motor. Refer to

Figure 15 on page 27

for

sample label. Several curves are shown on

the label, one for each size unit. Refer to the

0 to 2.5 volt scale on the label and use the

voltmeter to read the voltage across TP1 and

TP3 to determine desired airflow setting.

Changing the factory setting for minimum

and maximum CFMs will invalidate the

range for the Fan Calibration Curve as it

will narrow the scale of the input signal.

7. Follow instructions for adjusting EC motor speed

using the G3 PWM board. Separate instructions

are provided for Three Speed (adjustable) and 2 –

10 VDC Proportional motor control modes.

LD19222

2-10V Manual

Max

High

Medium

Low

Min

10.0 VDC

7.5 VDC

6.0 VDC

4.0 VDC

2.0 VDC

0.88 VDC

0.70 VDC

0.53 VDC

0.35 VDC

0.18 VDC

Max

High

Medium

Low

Min

0

100

200

300

400

500

600

700

Airflow (SCFM)

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.00

ESP

(inches w

.g.)

HORIZONTAL LOW PROFIL PLENUM SIZE 30 FAN CALIBRATION CURVE:

CONSTANT-RPM EC MOTOR

3 Row, 10 FPI, 1” Throwaway filter

FIGURE 14 -

CONSTANT RPM AND CONSTANT

TORQUE EC MOTORS EXAMPLE FAN

CALIBRATION CURVE

2.0

6.8

5.2

8.4

10.0

2.8

9.2

7.6

6.0

4.4

3.6

LD19223

Remote Analog Adjustment Voltage (VDC)

2000

200

400

600

800

1000

1200

1400

1600

1800

0

Airflow (CFM)

0.00

2.25

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

2.50

HORIZONTAL LOW PROFILE PLENUM

FAN CALIBRATION CURVE: CONSTANT-CFM EC MOTOR

Manual Adjustment Voltage (VDC)

60

50

40

20

30

25

FIGURE 15 -

CONSTANT AIRFLOW AND

CONSTANT TORQUE EC MOTORS EXAMPLE FAN

CALIBRATION CURVE

Adjusting EC Motor Speed

This section contains instructions for using the G3

PWM board to adjust the EC motor speed for balanc-

ing purposes. There are two modes of EC motor speed

control: Three Speed operation at three fixed (adjust-

able) speeds, or Proportional Control with remote 2 –

10 VDC signal.

For units with electric heat, fan speed

must not be adjusted below 70 CFM/kW.

Содержание VHA

Страница 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 22: ...ENVIRO TEC 22 FORM ET115 24 NOM4 819 SECTION 1 RECEIPT INSTALLATION THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Страница 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...