57

10. MONITOR DISPLAYS AND STEPS TO TAKE

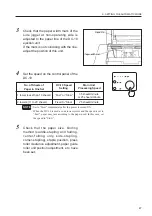

• The control panel is equipped with monitor lamps which indicate the location of problems

which have occurred.

Take the following steps when these monitor lamps light up.

• Sometimes, paper may remain in the conveyance route of the DC-10. Remove them.

• Always remove the jammed paper inside the unit before performing forced-paper ejection in

the DC-10.

State

Remedy

Cause

The staple detection lamp lights

up and the unit stops operating.

Paper jam lamp for the paper

receiving tray lights up and the

unit stops running.

The conveyer paper jam lamp

lights up and the unit stops

operating.

The peripheral device error lamp

lights up and the unit stops

operating.

All error lamps light up

• There are no more staple in the

stapler head or only a few are

left.

• Paper has jammed inside the

paper receiving tray.

Or the paper receiving tray has

become full of bound paper.

Paper has jammed inside the

conveyer of the unit.

• Paper has jammed before staple

processing.

→

The paper is not aligned

neatly.

• P a p e r h a s j a m m e d b e f o r e

folding.

→

Paper has not been conveyed

properly from the saddle-

stapling stopper to the folding

position stopper.

• The paper did not pass through

the press roller.

→

The folded paper is not

ejected.

• Error of the upstream processing

device or device connected after

the unit.

• The top cover or belt conveyance

unit is open.

• Replace the staple cartridge.

NOTE

: The staples can be used up

by turning off the staple

detection ON/OFF key.

However, operations will

continue even when no

more staples are left.

• Remove the paper jammed at

the paper ejection slot of the unit.

NOTE

: If there is paper in the

conveyance route of the

DC-10, remove them.

• Remove the paper jammed, and

check that the paper size, number

of sheets, and paper weight are

within the specification.

• Check the back/side jogger

position.

• Change the amount of paper

overlap.

• Is the side jogger width set too

narrow?

• Replace the ball of the ball unit

with a metallic one.

• Set the clearance adjusting lever

to the larger value.

• Clean the press roller if it is dirty.

• Look at the control panel of the

DC-10 if it is connected.

• Close properly.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Содержание DBM-100

Страница 1: ...STAPLER FOLDER DBM 100 INSTRUCTION MANUAL ...

Страница 8: ...6 3 NAMES AND OPERATION OF PARTS 3 1 External Parts ...

Страница 10: ...8 3 NAMES AND OPERATION OF PARTS 3 2 Internal Parts ...

Страница 64: ...This manual is printed on recycled paper to help protect the environment 98R 90258 98070200M 0 ...