Vehicle System

Testing and Adjusting

68

Brake Assembly

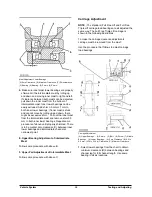

(3) Adjustment screw. (4) Adjustment lever.

4.

Turn adjustment screw (3) up until a heavy

resistance (drag) is felt on the brake shoes as the

drum is turned.

5.

Put a thin blade screwdriver into hole and hold

adjustment lever (4) away from the adjustment

screw.

NOTE:

The adjustment lever must be held away

from the adjustment screw when the adjustment

screw is turned backwards.

6.

Put the brake tool through a hole into a tooth on

the adjustment screw and turn screw (3)

backward until the brake shoes are free of

resistance (drag).

7.

Do steps 3 through 6 to adjust the other brake

lining to drum clearance.

8.

Install the plugs. Test the brake to be sure that

both that wheels stop evenly when a brake

application is made.

9.

If required, conduct the burning on the brake

shoes and linings for 5 ~ 10 minutes.

Pedal Adjustment

The brake pedal must have proper free play to let

the master cylinder piston return to the release

position and open the relief outlet.

Approximately 5 mm of free play on the pedal is

required.

Hydraulic pressure in the brake lines goes back

through the relief opening and releases the brakes.

If there is no pedal free play, the pressure can not

go back through the relief opening, and the brakes

will tighten and not release.

If there is too much free play, the brake pedal will

below even with the correct brake adjustment.

The master cylinder push rod must be adjusted so

the brake pedal has 3 to 8 mm (.118 to .315 in) of

free play from the pedal stop to the push rod contact

point with the master cylinder piston.

Location of Master Cylinder

(1) Master Cylinder. (2) rod.9

If the pedal adjustment is not correct, do the

procedure that follows:

1.

Remove Accel. Pedal for removing floor plate.

Содержание D20G

Страница 2: ......

Страница 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Страница 14: ......

Страница 16: ......

Страница 34: ...Diesel Engine Engine Identification 20 1 Exhaust Valve Port 2 Exhaust Manifold 00900232 Exhaust System ...

Страница 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Страница 199: ...Diesel Engine Engine System 185 Install the needle valve and nozzle assembly Install the nozzle nut fi900ce fi900ob ...

Страница 254: ......

Страница 256: ......

Страница 260: ......

Страница 334: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 80 Cylinder Head Cylinder Head Components 4TNV98 Engine Figure 6 36 ...

Страница 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Страница 363: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 109 Crankshaft and Camshaft Components Figure 6 84 ...

Страница 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Страница 425: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 171 Structure And Operation Of Fuel Injection Pump Figure 7 3 ...

Страница 468: ...4TNV98 4TNE98 Diesel Engine Section 6 Lubrication System 214 Lubrication System Diagram Figure 9 1 ...

Страница 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Страница 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Страница 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Страница 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Страница 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Страница 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Страница 500: ......

Страница 502: ......

Страница 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Страница 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Страница 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Страница 611: ...G424F FE Service Manual Chapter 4 Engine Electrical System 111 2 Alternator and outer terminal connection inspection ...

Страница 649: ...G424F FE Service Manual Chapter 5 Engine Management System EMS 149 Figure 22 SECM Wiring Diagram for G424FE LP System ...

Страница 727: ...G424F FE Service Manual 227 Chapter 8 Basic Troubleshooting Irregular Idling Or Engine Is Suddenly Stopped ...

Страница 728: ...G424F FE Service Manual 228 Chapter 8 Basic Troubleshooting Engine Hesitation Or Insuffient Accelelation ...

Страница 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Страница 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Страница 806: ......

Страница 808: ......

Страница 810: ......

Страница 820: ...Power Train System Operation 14 Hydraulic System ...

Страница 822: ...Power Train System Operation 16 Hydraulic System ...

Страница 824: ...Power Train System Operation 18 Hydraulic System ...

Страница 826: ...Power Train System Operation 20 Hydraulic System ...

Страница 856: ......

Страница 858: ......

Страница 860: ......

Страница 930: ......

Страница 932: ......

Страница 934: ......

Страница 936: ......

Страница 1018: ......

Страница 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Страница 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Страница 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Страница 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Страница 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Страница 1028: ......

Страница 1030: ......

Страница 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Страница 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...