Table 28 – Error Codes 2 Stage PSC furnace

Green

LED

FLash

Amber

LED

Flash

Red

LED

Flash

Erreur/Conditions

Comments/Troubleshooting

Furnace doesn’t operate.

Control

board LED’s are off.

Door switch is defective or open. There is no

120V to the board.

1

Flame sense when no flame should

be present.

Verify the gas valve is operating and shutting

down properly. Flame in the burner assembly

should extinguish promptly at the end of the

cycle.

2

Pressure switch stuck closed

Faulty pressure switch, pressure switches

wires shorted, control board inducer relay

stuck closed

3

First stage pressure switch stuck

open

Faulty pressure switch or tubing or wiring,

control board inducer relay failed, restriction

at the vent, blocked vent

4

High limit and/or rollout switch open

Verify temperature rise and airflow, duct static

pressure, burners alignment, wiring to both

switch (high limit and rollout).

5

Open fuse or roll out switch

Check fuse and replace. Check roll out switch

6

Pressure switch lockout, pressure

switch has opened 5 times in a

heating cycle.

Check for venting restriction, verify pressure

switch tubing for leaks.

7

Lockout after multiple failed ignition.

Check gas pressure and gas valve. Make

sure flame rod is clean and properly wired.

Check ignitor and its connection.

8

Lockout after multiple flame lost.

Check gas pressure and gas valve. Make

sure flame rod is clean and properly wired.

9

Improper grounding or polarity

120V hot and neutral reversed. 120V should

be read between Hot and ground. 0V should

be read between Neutral and ground.

10

Gas valve current detected with no

call for heat.

Verify if any electrical short could send

voltage/current to the gas valve.

If not,

replace control board.

11

Open limit switch

Reset

the

unit

and

verify

blower

is

functionning

at

proper

speed.

Verify

temperature rise and airflow, duct static

pressure, burners alignment, wiring to both

switch (high limit and rollout).

12

Ignitor relay on control board is not

functionning.

Replace control board.

Solid

ON

Internal control board error

Reset control. Replace control board if error

code is still present.

Rapid

Twinning

error

(Twinning

is

not

recommanded)

Don’t twin your furnaces.

3

double

Second stage pressure switch stuck

open.

Check for faulty pressure switch, tubing or

wiring. Check for restriction at the vent. Make

sure inducer blower is functionning properly.

1

Normal operation with call for first stage

heating.

2

Normal operation with call for second stage

heating.

3

Call on W2 without call on W1

Verify thermostat and wiring.

4

Call on Y or Ylo without call on G

Verify thermostat and wiring.

Rapide

Low flame sense

Clean flame rod with steel wool. Check gas

outlet pressure.

1

Normal operation with call for 1st stage

cooling.

2

Normal operation with call for 2nd cooling or

Single stage cooling.

Rapid

Normal operation with call for fan on.

Solid

On

Normal operation, standby mode

37

Содержание C105-1-D

Страница 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Страница 25: ...Figure 28 Direct vent clearance 24...

Страница 26: ...Figure 29 Other than Direct vent clearance 25...

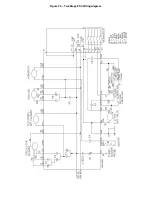

Страница 34: ...Figure 32 Single Stage PSC Wiring diagram...

Страница 35: ...Figure 33 Two Stage PSC Wiring diagram...

Страница 36: ...Figure 34 Single Stage ECM Wiring diagram...

Страница 39: ...Figure 35 Dimensions 38...

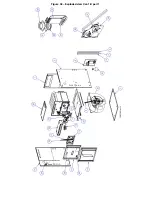

Страница 40: ...Figure 36 Exploded view CXX 1 X part 1...

Страница 41: ...Figure 37 Exploded view CXX 1 X part 2...

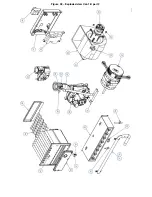

Страница 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Страница 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Страница 46: ...Figure 40 Exploded view Cxx 2 D part 1...

Страница 47: ...Figure 41 Exploded view Cxx 2 D part 2...