2

INTRODUCTION

This multiposition Category IV condensing furnace is

CSA design certified direct vent (2 pipes) or non-direct

vent (1 pipe). The furnace is factory shipped for use

with natural gas. The furnace can be converted in the

field for use with propane gas when a factory supplied

conversion kit is used. Refer to the furnace rating plate

for conversion kit information and part list table

This furnace is designed for minimum continuous return

air temperature of 60 °F (16 °C) or intermittent operation

down to 55 °F (13 °C) such as when used with a

night setback thermostat. Return air temperature must

not exceed 80 °F (27 °C). Failure to follow these

return air temperature limits may affect reliability of heat

exchangers, motors, and controls.

The furnace should be sized to provide at least 100

% of the design heating load requirement.

Heating

load estimates can be made using approved methods

available from Air Conditioning Contractors of America

(Manual J); American Society of Heating, Refrigerating,

and Air Conditioning Engineers; or other approved

engineering methods.

Excessive over sizing of the

furnace could cause the furnace and/or vent to fail

prematurely.

2.1

CODES AND STANDARDS

Follow all national and local codes and standards in

addition to these instructions.

The installation must

comply with regulations of the serving gas supplier, local

building, heating, plumbing, and other codes. In absence

of local codes, the installation must comply with the

national codes listed below and all authorities having

jurisdiction. In the United States and Canada, follow all

codes and standards for the following:

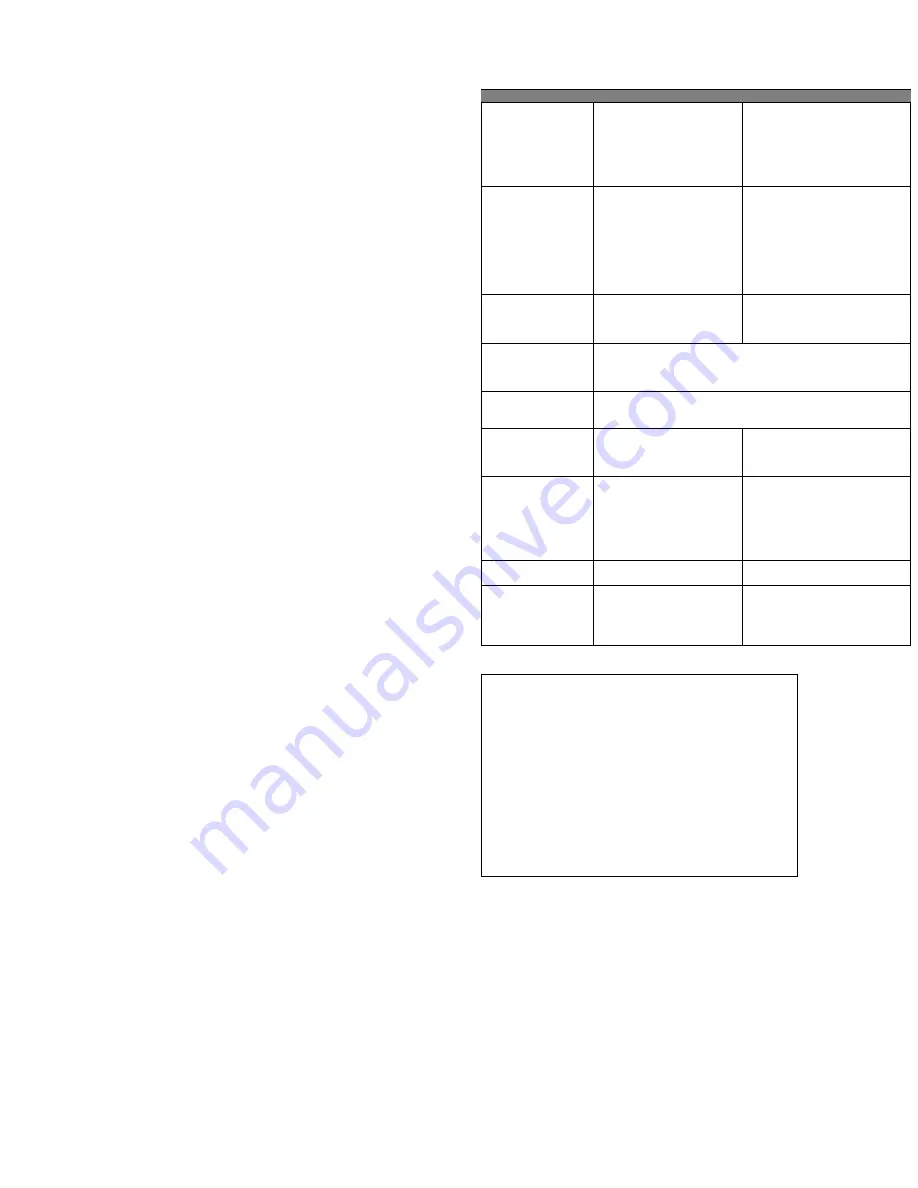

Table 1 – Codes and Standards

TOPIC

USA

CANADA

Safety

National Fuel Gas Code

(NFGC)

NFPA

54-

2009/ANSI

Z223.1

and

the Installation Standards,

Warm

Air

Heating

and

Air

Conditioning

Systems

ANSI/NFPA 90B

National

Standard

of

Canada, Natural Gas and

Propane Installation Code

(NSCNGPIC)

CAN/CSA

B149.1

General

installation

NFGC and the NFPA 90B.

For

copies,

contact

the

National

Fire

Protection

Association

Inc.,

Battery

march Park, Quincy, MA

02269; or for only the NFGC

contact the American Gas

Association, 400 N. Capitol,

N.W.,Washington DC 20001

NSCNGPIC. For a copy,

contact

Standard

Sales,

CSA

International,

178

Rexdale

Boulevard,

Etobicoke

(Toronto),

Ontario, M9W 1R3, Canada

Combustion

and

and air ventilation

Section

9.3

of

the

NFPA54/ANSI

Z223.1

Air

for

Combustion

and

Ventilation

Part 8 of the CAN/CSA

B149.1,

Venting Systems

and

Air

Supply

for

Appliances

Duct systems

Air Conditioning Contractors Association (ACCA) (Manual

D), Sheet Metal and Air Conditioning Contractors National

Association (SMACNA), or American Society of Heating,

Refrigeration, and Air Conditioning Engineers (ASHRAE).

Acoustical

lining

and fibrous glass

duct

current edition of SMACNA, NFPA 90B as tested by UL Standard

181 for Class I Rigid Air Ducts.

Gas

piping

and

pipe

pressure

testing

NFPA

54/ANSI

Z223.1

NFGC; Chapters 5, 6, 7,

and 8 and national plumbing

codes.

CAN/CSA-B149.1, Part 6

Manufactured

Mobile housing

Manufactured

Home

Construction

and

Safety

Standard,

Title 24 CFR,

Part 3280 or The Standard

for

Manufactured

Home

Installations

ANSI/NCS

A225.1

Canadian

Standard

for

Series M92 Mobile Homes,

CAN/CSA Z240MH

Electrical

connections

National

Electrical

Code

(NEC) ANSI/NFPA 70

Canadian Electrical Code

CSA C22.1

Venting

Part

7,

Venting

of

equipment, latest edition of

the National Fuel Gas Code

NPFA 54, 90A and 90B

ANSI Z223.1-

CAN/CSA-B149.1-05 latest

edition

IN THE STATE OF MASSACHUSETTS:

• This product must be installed by a

licensed plumber of gas fitter;

• When flexible connectors are used, the

maximum length shall not exceed 36 in.

(914 mm);

• When lever type gas shutoffs are used

they shall be ”T” handle type;

• The use of copper tubing for gas

piping is not approved by the state of

Massachusetts;

6

Содержание C105-1-D

Страница 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Страница 25: ...Figure 28 Direct vent clearance 24...

Страница 26: ...Figure 29 Other than Direct vent clearance 25...

Страница 34: ...Figure 32 Single Stage PSC Wiring diagram...

Страница 35: ...Figure 33 Two Stage PSC Wiring diagram...

Страница 36: ...Figure 34 Single Stage ECM Wiring diagram...

Страница 39: ...Figure 35 Dimensions 38...

Страница 40: ...Figure 36 Exploded view CXX 1 X part 1...

Страница 41: ...Figure 37 Exploded view CXX 1 X part 2...

Страница 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Страница 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Страница 46: ...Figure 40 Exploded view Cxx 2 D part 1...

Страница 47: ...Figure 41 Exploded view Cxx 2 D part 2...