SECTION 3.5

DDFP

Page 33

MANUAL START INSTRUCTIONS

The engine can be operated without using the engine con-

troller. Use the following procedure when manual starting is

required. Refer to Fig. 2, Page 32.

To Start Engine

1. OPEN COOLING SYSTEM MANU

AL BYP ASS

VALVE. Located on the cooling loop, Fig. 8, Page 29.

2. POSITION

MODE

SELECTOR IN

MANUAL

RUN.

Fig. 3, Page 32.

3. POSITION

BATTERY SELECTOR

SWITCH T O

BATT. #1.

4. PULL AND HOLD MANUAL CONTACTOR #1, Fig.

4, Page 32 UNTIL ENGINE ST

ARTS, RELEASE

AFTER 5 SECONDS. IF UNIT F AILS TO ST ART,

POSITION

BATTERY SELECTOR

TO B #2 USE

STARTER CONTACTOR #2, AND REPEAT STEP.

To Stop Engine

1. RETURN

MODE SELECTOR

TO

AUTOMATIC,

AND

MANUAL STOP,

ENGINE WILL STOP.

2. CLOSE COOLING SYSTEM MANU AL BY -PASS

VALVE.

IMPORTANT:

DO NOT

LEAVE THE

MODE SELECTOR

SWITCH

IN THE

MANUAL RUN

POSITION DURING

AUTO-

MATIC

OPERATION. (THE CONTROLLER WILL BE

UNABLE TO STOP THE ENGINE AND

OVERHEAT

DAMAGE WILL RESULT

)

DO NOT

POSITION THE

BATTERY SELECTOR

SWITCH TO A DEFECTIVE B ATTERY WHILE IN

THE

MANUAL MODE.

GOVERNOR OPERATING SOLENOID

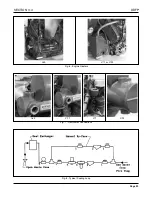

The DC go vernor solenoid, Fig. 6, Page 32, is an essential

item for the operation of this fire pump system. Upon receiv-

ing a signal, the solenoid is energized to move the governor

into the run position.

This solenoid remains ener gized during engine operation.

To stop the engine, the solenoid de-energizes and the gover-

nor returns to the "no fuel" position by spring action.

INSTRUMENTATION

Figure 7, Page 32 sho ws the instrumentation panel which

contains the follo wing gauges: tachometer with inte gral

hourmeter (1), engine oil pressure (P.S.I.) (2), battery volt-

meter (3), engine coolant temperature (°F) (4), battery isola-

tor (5). Engine overspeed switch is mounted to rear of gauge

panel Figure 8.

Tachometer and Integral Hourmeter -

This meter re-

ceives its signal from the o verspeed switch to allo w operator

to read engine RPM, in addition the hour meter records a

cumulative total of engine operating hours.

Oil Pressure -

This mechanical gauge gives engine oil pres-

sure readings in english and metr ic units (PSI & kP A). Con-

nection location to the engine will vary per engine model.

Engine Coolant Temperature -

This temperature gauge

indicates the engines coolant outlet temper ature in de grees

fahrenheit (°F) and centrigrade (°C).

Voltmeter -

This gauge identifies the voltage level of the bat-

tery according to the position of the ba ttery selector switch.

SPEED SWITCH

After the engine has started and reached 1000 RPM,the speed

switch signals the contr oller to terminate the starter cranking

action. An overrunning clutch is included on the star ter drive

to prevent damage from overspeeding when the unit starts.

NOTE:

When starting unit with man ual contactor s, re-

lease contactor handle as soon as eng ine starts.

In the event of an engine o verspeed the speed s witch signals

the AEC and ef fects an engine shutdo wn. A MANU AL

RESET button is included on the switch and must be "pushed

in" to reset the speed s witch after unit has shutdo wn from an

Fig. 8 - Overspeed Reset

➞

➞

Содержание DDFP Series

Страница 13: ...DDFP SECTION 2 Front View V 71 Page 9 A Front View I 71 Right Side View I 71 Right Side View 6V 71 ...

Страница 14: ...Page 9 B SECTION 2 DDFP Front View 12V 92 Left Side View 12V 92 Front View V 92 Right Side View V 92 ...

Страница 22: ...SECTION 3 2 DDFP AIR FILTER SERVICE INSTRUCTIONS Figure 1 Air Filter Service Instructions Page 17 ...

Страница 42: ...SECTION 3 5 DDFP Page 37 Fig 13 DC Wiring Diagram Engines With Mechanical Guages ...

Страница 43: ...DDFP Fig 14 DC Wiring Diagram Engines With Electrical Guages Page 38 SECTION 3 5 ...

Страница 44: ...SECTION 3 5 DDFP Page 39 Fig 15 AC Wiring Diagram ...