DDFP

SECTION 3.4

Page 28

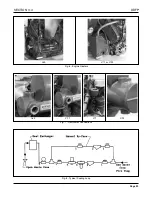

COOLANT PUMP

The engine water pump is a centrifugal impeller type pump.

It is gear dri ven on the I-71, V-71 and V-92 Series engines

and belt driven on the I-53 Series engines. The rebuildable

pump utilizes a shaft and sealed bearing assembly. The V-71

and V-92 incorporate an oil seal and tw o splash lubricat-

ed ball type bearings. Each pump also included a w

ater

pump seal weep hole. Should a coolant leak occur at this

location, the pump seal must be replaced. Contact your local

DDC Distrib utor/Dealer for assistance. Should a replace-

ment pump be required for repair , use only the e xact same

type of pump.

THERMOSTAT

Each pump engine is equipped with a temperature control-

ling thermostat(s). Normal operating ranges will vary due to

engine horsepower and operating speed. The thermostat(s)

are located at the front of the c

ylinder heads. Refer to

Section 5 for specif ic operating temperatures for each

engine.

ENGINE COOLANT HEATER

Fire pump engines must be able to assume full load imme-

diately when used for emergency service. NFPA-20 specifi-

cations require an engine coolant heater Figure 6, Page 29,

to maintain a minimum temperature of 120° F

. (49° C).

Maintaining this temperature assists the engine to start eas-

ily and produce rated horsepo wer immediately . F or f ire

pump units operation in cold climates optional oil heaters

are a vailable to k eep the engines lubricating oil at a safe

temperature for emer gency start purposes. If pump room

temperatures drop belo w 50° F (10° C),

oil heaters are

required.

On the initial installation of each f ire pump engine, it is the

responsibility of the installing contractor to wire the heater

to the pump room AC circuit. See Section 3 Electrical AC

Wiring Diagram, Page 39, for correct wiring to the heater

disconnect switch.

CAUTION:

Do not acti vate the AC circuit unless the

engine cooling system has been filled.

A pre-mix solution must be used. Chemical

reactions will occur if pure Ethylene Glycol

anti-freeze is allo wed to f ill the heater ca vity

with AC circuit is activated.

HEAT EXCHANGER COOLING

The heat e xchanger cooling system is illustrated in Fig.

1,

Page 25.

Raw water from the f ire pump passes through the heat e x-

changer core where it lowers the engine coolant temperature

10-15° F (-12° – -9° C). Typical raw water connection points

on the heat exchanger are shown in Fig.

7,

Page 29.

HOSES

Specific areas on each DDFP engine use hoses to transfer

coolant to and from heat exchangers and immersion heaters.

Regular inspections are necessary to v erify that no leaks

exist. Should replacements be required contact your local

DDC Distributor/Dealer for assistance.

NOTE:

Silicon Hose material for the immersion heaters

must meet SAE J20 Requirements with a maxi-

mum heat operating range of 350° F (177° C). Do

not replace these hoses with any other type materi-

al.

NOTE:

Hose clamps required for silicon type hose, must

have a shielded inner band or be of a constant

torque type (spring loaded). If the second type is

used, do not collapse spring by over tightening.

Содержание DDFP Series

Страница 13: ...DDFP SECTION 2 Front View V 71 Page 9 A Front View I 71 Right Side View I 71 Right Side View 6V 71 ...

Страница 14: ...Page 9 B SECTION 2 DDFP Front View 12V 92 Left Side View 12V 92 Front View V 92 Right Side View V 92 ...

Страница 22: ...SECTION 3 2 DDFP AIR FILTER SERVICE INSTRUCTIONS Figure 1 Air Filter Service Instructions Page 17 ...

Страница 42: ...SECTION 3 5 DDFP Page 37 Fig 13 DC Wiring Diagram Engines With Mechanical Guages ...

Страница 43: ...DDFP Fig 14 DC Wiring Diagram Engines With Electrical Guages Page 38 SECTION 3 5 ...

Страница 44: ...SECTION 3 5 DDFP Page 39 Fig 15 AC Wiring Diagram ...