InfraSuite - CoolDoor

26

3.7

External Piping

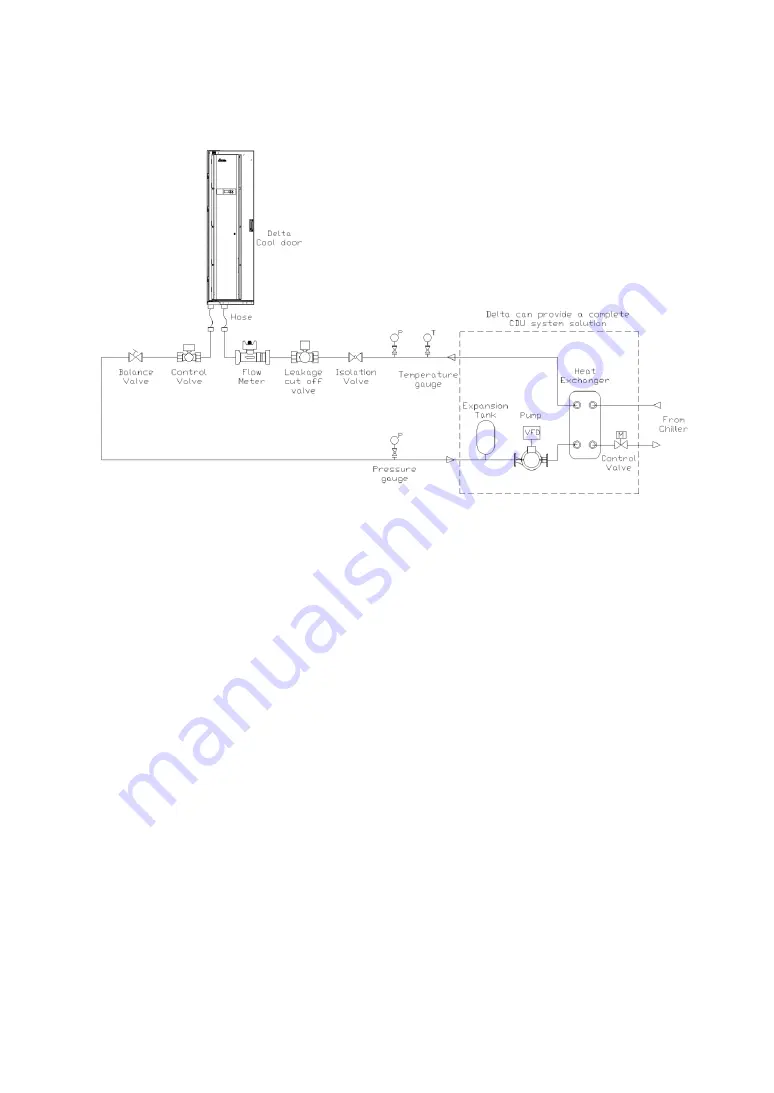

(Figure 3-9: External Piping)

As shown in

Figure 3-9

, the door of the CoolDoor will open and close during application.

Therefore, pipes must be fitted at the water inlet and outlet. Note that the soft tubes and

connections must be able to have acceptable rotation. The standard of connection is a screw

cross-over joint, or an optional quick joint. Install the ball valve provided by Delta on the

outlet pipe behind the soft tube. After the external pipeline is established, it is recommended

that you hold the pressure to check whether the connections are leaking or not. The holding

pressure should not be higher than the maximum pressure of the CoolDoor, 142 psig. Delta

recommends installing isolation valves on the water outlet before the ball valve of the

CoolDoor and on the water inlet before the soft tube, which will allow for maintenance and

disassembly.

Delta recommends using a closed water system for chilled water supply. The system has

independent pumps, expansion tanks, and heat exchangers to prevent outside pollution from

entering the system and ensure the operating efficiency of the CoolDoor.

•

Pipeline washing

To guarantee cooling efficiency, you must purify the pipeline to filter out impurities and

chemical substances. For pipeline washing, use a hose to create a short circuit that

makes the chilled water go directly from the inlet end to the return end, without passing

through the cooling unit. If your pipeline system has a Y-filter, please install a fine-

meshed filter (20-mesh suggested) in it to filter out the fine impurities; after 12h-24h of

water circulation in the pipeline, change to a larger-meshed filter (3-mesh suggested).