23

Natural Gas Capacity of Pipe

In Cubic Feet of Gas Per Hour (CFH)

Length of

Nominal Black Pipe Size

Pipe in Feet

1/2"

3/4"

1"

1 1/4"

1 1/2"

10

132

278

520

1050

1600

20

92

190

350

730

1100

30

73

152

285

590

980

40

63

130

245

500

760

50

56

115

215

440

670

60

50

105

195

400

610

70

46

96

180

370

560

80

43

90

170

350

530

90

40

84

160

320

490

100

38

79

150

305

460

(Pressure 0.5 psig or less and pressure drop of 0.3" W.C.; Based on

0.60 Specific Gravity Gas)

CFH =

BTUH Furnace Input

Heating Value of Gas (BTU/Cubic Foot)

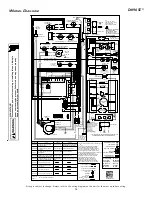

The gas piping may enter the left or right side of the

furnace cabinet. The installer must supply rigid pipe long

enough to reach the outside of the cabinet to seal the grom-

met cabinet penetration. A semi-rigid connector to the gas

piping can be used outside the cabinet per local codes. 1/2”

NPT pipe and fittings are required. For models with an

“L” shaped manifold, a 4 1/2” long nipple is required.

For models with a hook shaped manifold, a 2” long nipple

is required.

A semi-rigid connector to the gas piping can be used out-

side the cabinet per local codes. From the elbow, the length

of pipe and the fittings required will vary by the side cho-

sen, location of union and cabinet width. The union may

be placed inside or outside of the cabinets.

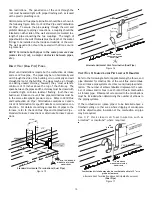

Alternate

Gas Line

Location

Plug in

Alternate

Gas Line

Hole

* Ground

Joint

Pipe

Union

Gas Valve

*Ground

Joint

Pipe

Union

Manual Shut Off Valve

(upstream from

ground joint

pipe union)

Grommet

in Standard

Gas Line

Hole

Drip Leg

Burners

Manifold

* NOTE: Union may be inside furnace cabinet where allowed by local codes.

UPFLOW

Figure 27

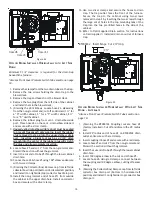

Manual Shut Off Valve

(upstream from

ground joint pipe union)

Drip Leg

Plug in Alternate Gas Line Hole

Grommet in

Standard Gas Line Hole

Alternate

Union

Location

Burners

Drain Trap

Gas Valve

Plug in Main Gas Line Hole

Manifold

UPFLOW - HORIZONTAL LEFT

Figure 28

G

AS

P

IPING

C

HECKS

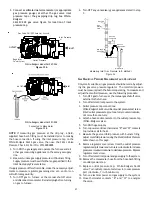

Before placing unit in operation, leak test the unit and gas con-

nections.

Check for leaks using an approved chloride-free soap and water

solution, an electronic combustible gas detector, or other ap-

proved testing methods.

NOTE:

Never exceed specified pressures for testing. Higher

pressure may damage the gas valve and cause subsequent

overfiring, resulting in heat exchanger failure.

Disconnect this unit and shutoff valve from the gas supply piping

system before pressure testing the supply piping system with

pressures in excess of 1/2 psig (3.48 kPa).

Isolate this unit from the gas supply piping system by closing its

external manual gas shutoff valve before pressure testing supply

piping system with test pressures equal to or less than 1/2 psig

(3.48 kPA).

C

IRCULATING

A

IR

& F

ILTERS

D

UCT

WORK

- A

IR

F

LOW

Duct systems and register sizes must be properly designed for

the CFM and external static pressure rating of the furnace. De-

sign the ductwork in accordance with the recommended meth-

ods of “Air Conditioning Contractors of America” Manual D.

Install the duct system in accordance with Standards of the Na-

tional Board of Fire Underwriters for the Installation of Air Condi-

tioning, Warm Air Heating and Ventilating Systems. Pamphlets

No. 90A and 90B.

Содержание DM96SE

Страница 37: ...37 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 38: ...38 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 39: ...39 THIS PAGE LEFT INTENTIONALLY BLANK ...