25

Model

Minimum Recommended Filter Size^

DM96SE0403BU*

1 - 16 X 25 Side or Bottom

DM96SE0603BU*

1 - 16 X 25 Side or Bottom

DM96SE0805BU*

1 - 20 X 25 Bottom / 2 - 16 X 25 Side Return

Filter Sizing Chart

^ Larger filters may be used, filters may also be centrally located

Change filters before occupants take ownership of a new home.

Consider installing an air cleaner with deep-pleated media

filter at the time of furnace installation. A deep-pleated fil-

ter with a MERV rating of 8 (minimum) will often provide

better filtration to protect equipment and the air distribu-

tion system than a standard 1" filter and often has lower

static pressure loss than a 1" filter. Also a deep-pleated filter

will typically require less frequent replacement intervals. Avoid

using highly restrictive 1" filters which produce static pres-

sure loss greater than .25" W.C. In some installations the

minimum filter size required (consult filter sizing chart on

page 34) will not lend itself to a filter installation on the side

of the furnace. The installation of a centrally installed air

cleaner cabinet or a return duct filter installation may offer

more practicality.

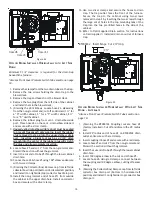

Clean Comfort™ brand MERV 11 air cleaners have 5¼” media

filters and are available in the following configurations. Con-

sult your distributor for information on our complete line of

IAQ Clean Comfort™ products.

Air Cleaner

Installation Location

Maximum

Heating Airflow

Filter (Media)

Dimensions

Part Number

Air Cleaner

Family

Side or bottom return

1200 CFM

16 in X 20 i n x 5¼"

AM11-1620-5

Side or bottom return

1600 CFM

16 in X 25 i n x 5¼"

AM11-1625-5

Side or bottom return

1600 CFM

20 in X 20 i n x 5¼"

AM11-2020-5

Side or bottom return

2000 CFM

20 in X 25 i n x 5¼"

AM11-2025-5

Side return

(for 2 sepa ra te returns)

Side return (Ri ght a ngl e)

2000 CFM

20 in X 25 i n x 5¼"

AM11-2025-5RA

AM11-5RA

Bottom return (pl a tform)

2000 CFM

20 in X 25 i n x 5¼"

AM11-2832-5PP

Bottom return (pl a tform)

2000 CFM

20 in X 25 i n x 5¼"

AM11-2843-5PP

AM11-5

2 X 1600 CFM

2, 16 in X 25 i n x 5¼"

AM11-3225-5

AM11-3225

AM11-5PP

AM11-5

AM11-5RA

AM11-5PP

Family

Family

Family

U

PRIGHT

I

NSTALLATIONS

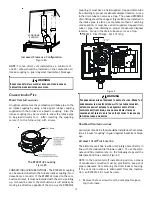

Depending on the installation and/or customer preference,

differing filter arrangements can be applied. Filters can be

installed in the central return register or a side panel exter-

nal filter rack kit (upflows). As an alternative a media air

filter or electronic air cleaner can be used as the requested

filter.

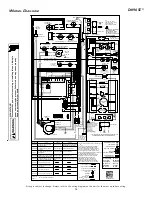

CUT FOUR CORNERS

AFTER REMOVING SHEET

METAL

CUT USING TIN SNIPS

PRESS OUT BY HAND

SCRIBE LINES OUTLINING

DUCT FLANGES

Duct Flange Cut Outs

Figure 30

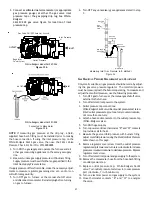

When the furnace is used in connection with a cooling unit, the

furnace should be installed in parallel with or on the upstream

side of the cooling unit to avoid condensation in the heating

element. With a parallel flow arrangement, the dampers or

other means used to control the flow of air must be adequate

to prevent chilled air from entering the furnace and, if manu-

ally operated, must be equipped with means to prevent opera-

tion of either unit unless the damper is in the full heat or cool

position.

When the furnace is installed without a cooling coil, it is rec-

ommended that a removable access panel be provided in the

outlet air duct. This opening shall be accessible when the

furnace is installed and shall be of such a size that the heat

exchanger can be viewed for visual light inspection or such

that a sampling probe can be inserted into the airstream. The

access panel must be made to prevent air leaks when the

furnace is in operation.

When the furnace is heating, the temperature of the return air

entering the furnace must be between 55°F and 100°F.

F

ILTERS

- R

EAD

T

HIS

S

ECTION

B

EFORE

I

NSTALLING

T

HE

R

ETURN

A

IR

D

UCT

WORK

Filters must be used with this furnace. Discuss filter mainte-

nance with the building owner. Filters do not ship with this

furnace, but must be provided, sized and installed externally

by the installer. Filters must comply with UL900 or CAN/

ULCS111 standards. Damage or repairs due to the installa-

tion of the furnace without filters are not covered under

the warranty.

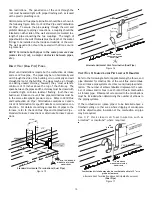

On upflow units, guide dimples locate the side return cutout

locations. Use a straight edge to scribe lines connecting the

dimples. Cut out the opening on these lines.

NOTE:

An under-

sized opening will cause reduced airflow.

Refer to the Filter Sizing Chart to determine filter area re-

quirements.

Содержание DM96SE

Страница 37: ...37 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 38: ...38 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 39: ...39 THIS PAGE LEFT INTENTIONALLY BLANK ...