21

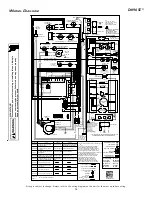

located on the blower compartment door, for further details

of 115 Volt and 24 Volt wiring.

R

Y

C

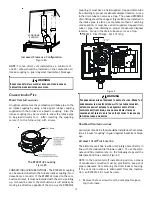

Furnace Integrated

Control Module

Remote Condensing Unit

(Single-Stage Cooling)

R

Room

Thermostat

Figure 26

S

INGLE

-S

TAGE

H

EATING

T

HERMOSTAT

A

PPLICATION

A single-stage thermostat with only one heating stage is

needed to control this furnace.

F

OSSIL

F

UEL

A

PPLICATIONS

This furnace can be used in conjunction with a heat pump in a

fossil fuel application. A fossil fuel application refers to a

combined gas furnace and heat pump installation which uses

an outdoor temperature sensor to determine the most cost

efficient means of heating (heat pump or gas furnace).

Strictly follow the wiring guidelines in the fossil fuel kit in-

stallation instructions. All furnace connections must be made

to the furnace integrated control module and the “FURNACE”

terminal strip on the fossil fuel control board.

G

AS

S

UPPLY

AND

P

IPING

WARNING

P

OSSIBLE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

MAY

OCCUR

IF

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

. T

HE

APPROPRIATE

KITS

MUST

BE

APPLIED

TO

ENSURE

SAFE

AND

PROPER

FURNACE

OPERATION

. A

LL

CONVERSIONS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER

OR

SERVICE

AGENCY

.

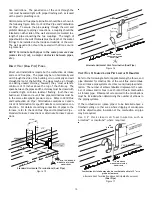

T

O

AVOID

POSSIBLE

UNSATISFACTORY

OPERATION

OF

EQUIPMENT

DAMAGE

DUE

TO

UNDERFIRING

OR

EQUIPMENT

,

USE

THE

PROPER

SIZE

OF

NATURAL

GAS

PIPING

NEEDED

WHEN

RUNNING

PIPE

FROM

THE

METER

/

TANK

TO

THE

FURNACE

.

WARNING

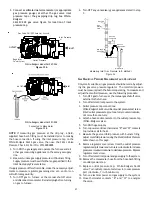

Natural Gas

Minim um : 4.5" w.c. Maxim um : 10.0" w.c.

INLET GAS SUPPLY PRESSURE

The furnace rating plate includes the approved furnace gas

input rating and gas types. The furnace must be equipped to

operate on the type of gas applied. This includes any conver-

sion kits required for alternate fuels and/or high altitude.

HIGH VOLTAGE !

T

O

AVOID

THE

RISK

OF

ELECTRICAL

SHOCK

,

WIRING

TO

THE

UNIT

MUST

BE

POLARIZED

AND

GROUNDED

.

WARNING

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

SERVICING

OR

CHANGING

ANY

ELECTRICAL

WIRING

.

WARNING

L

ABEL

ALL

WIRES

PRIOR

TO

DISCONNECTION

WHEN

SERVICING

CONTROLS

. W

IRING

ERRORS

CAN

CAUSE

IMPROPER

AND

DANGEROUS

OPERATION

. V

ERIFY

PROPER

OPERATION

AFTER

SERVICING

.

CAUTION

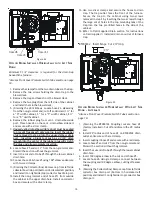

Line voltage connections can be made through either the

right or left side panel. The furnace is shipped configured

for a left side electrical connection. To make electrical con-

nections through the opposite side of the furnace, the junc-

tion box must be relocated to the right side prior to making

electrical connections. To relocate the junction box, perform

the following steps.

1. Remove the burner compartment door.

2. Remove and save the two screws securing the junction

box to the side panel.

3. Relocate junction box and associated plugs and grommets

to opposite side panel. Secure with screws removed in

step 2.

To ensure proper unit grounding, the ground wire should run

from the furnace ground screw located inside the furnace junc-

tion box all the way back to the electrical panel.

NOTE:

Do not

use gas piping as an electrical ground. To confirm proper unit

grounding, turn off the electrical power and perform the follow-

ing check.

1. Measure resistance between the neutral (white) connection

and one of the burners.

2. Resistance should measure 10 ohms or less.

This furnace is equipped with a blower door interlock switch which

interrupts unit voltage when the blower door is opened for ser-

vicing. Do not defeat this switch.

24 V

OLT

T

HERMOSTAT

W

IRING

Low voltage connections can be made through either the right or

left side panel. Thermostat wiring entrance holes are located in

the blower compartment. The following figure shows connec-

tions for a “heat/cool system”.

This furnace is equipped with a 40 VA transformer to facilitate

use with most cooling equipment. Consult the wiring diagram,

Содержание DM96SE

Страница 37: ...37 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 38: ...38 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 39: ...39 THIS PAGE LEFT INTENTIONALLY BLANK ...