30

O

PERATIONAL

C

HECKS

The burner flames should be inspected with the burner com-

partment door installed. Flames should be stable, quiet, soft,

and blue (dust may cause orange tips but they must not be

yellow). Flames should extend directly outward from the burn-

ers without curling, floating, or lifting off. Flames must not

impinge on the sides of the heat exchanger firing tubes.

S

AFETY

C

IRCUIT

D

ESCRIPTION

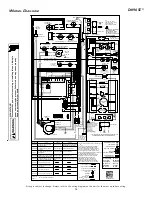

A number of safety circuits are employed to ensure safe and

proper furnace operation. These circuits serve to control any

potential safety hazards and serve as inputs in the monitoring

and diagnosis of abnormal function. These circuits are con-

tinuously monitored during furnace operation by the integrated

control module.

I

NTEGRATED

C

ONTROL

M

ODULE

The integrated control module is an electronic device which,

if a potential safety concern is detected, will take the neces-

sary precautions and provide diagnostic information through

an LED.

P

RIMARY

L

IMIT

The primary limit control is located on the partition panel and

monitors heat exchanger compartment temperatures. It is a

normally-closed (electrically), automatic reset, temperature-

activated sensor. The limit guards against overheating as a

result of insufficient conditioned air passing over the heat

exchanger.

A

UXILIARY

L

IMIT

The auxiliary limit controls are located on or near the circula-

tor blower and monitors blower compartment temperatures.

They are a normally-closed (electrically), manual-reset sen-

sors. These limits guard against overheating as a result of

insufficient conditioned air passing over the heat exchanger.

B

URNER

T

EMPERATURE

S

WITCH

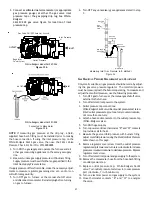

The Burner Temperature Switch is mounted on the burner

assembly and monitor the burner box temperature. It is

normally-closed (electrically), auto-reset sensor. This limit

guards against burner flames not being properly drawn into

the heat exchanger.

P

RESSURE

S

WITCHES

The pressure switches are normally-open (closed during op-

eration) negative air pressure-activated switches. They moni-

tor the airflow (combustion air and flue products) through the

heat exchanger via pressure taps located on the induced draft

blower and the coil front cover. These switches guard against

insufficient airflow (combustion air and flue products) through

the heat exchanger and/or blocked condensate drain condi-

tions.

F

LAME

S

ENSOR

The flame sensor is a probe mounted to the burner/manifold

assembly which uses the principle of flame rectification to

determine the presence or absence of flame.

P

RESSURE

S

ENSOR

Pressure sensor is mounted on the induced draft blower.

Its function is to regulate the induced draft blower’s speed

in order to maintain proper air-fuel ratio for clean and

reliable combustion.

T

ROUBLESHOOTING

E

LECTROSTATIC

D

ISCHARGE

(ESD) P

RECAUTIONS

NOTE:

Discharge body’s static electricity before touching unit.

An electrostatic discharge can adversely affect electrical

components.

Use the following precautions during furnace installation and ser-

vicing to protect the integrated control module from damage. By

putting the furnace, the control, and the person at the same

electrostatic potential, these steps will help avoid exposing the

integrated control module to electrostatic discharge. This pro-

cedure is applicable to both installed and uninstalled (ungrounded)

furnaces.

1. Disconnect all power to the furnace. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic

charge to ground.

2. Firmly touch a clean, unpainted, metal surface of the

furnace away from the control. Any tools held in a person’s

hand during grounding will be discharged.

3. Service integrated control module or connecting wiring

following the discharge process in step 2. Use caution not

to recharge your body with static electricity; (i.e., do not

move or shuffle your feet, do not touch ungrounded

objects, etc.). If you come in contact with an ungrounded

object, repeat step 2 before touching control or wires.

4. Discharge your body to ground before removing a new

control from its container. Follow steps 1 through 3 if

installing the control on a furnace. Return any old or new

controls to their containers before touching any ungrounded

object.

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

PERFORMING

ANY

SERVICE

OR

MAINTENANCE

.

WARNING

F

AULT

C

ODE

R

ETRIEVAL

Function:

When the SW1 button is pressed momentarily,

the control displays the last five (5) fault codes recorded

in non-volatile memory upon demand.

Operation:

The control must be powered and the ther-

mostat satisfied (no call for heat or cool). Depress and

release the SW1 button once (less than 5 seconds); the

Содержание DM96SE

Страница 37: ...37 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 38: ...38 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 39: ...39 THIS PAGE LEFT INTENTIONALLY BLANK ...