29

manufacturers recommend an air flow of about 400 CFM

per ton.

Example:

2.5 tons X 400 CFM per ton = 1000 CFM

3.

Select the heating speed for your model from the heating

speed chart in the Specification Sheet. The selected

speed must provide a temperature rise within the rise

range listed with the particular model.

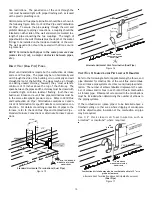

To adjust the circulator blower speed, proceed as follows:

1. Turn OFF power to the furnace.

2. Select the heating and cooling blower speeds that

match the installation requirements from the

airflow table in the Specification Sheet

.

3. Relocate desired motor leads to the circulator

blower heat and cool speed terminals on the

integrated control module. (Terminals are identified

as HEAT and COOL. If heating and cooling blower

speeds are the same, a jumper wire must be used

between the heat and cool terminals.

4. Connect all unused blower motor leads to the “PARK”

terminals on the integrated control module. Any

leads not connected to the “PARK” terminals must

be taped.

5. Turn ON power to furnace.

6. Verify proper temperature rise as outlined in the

Temperature Rise

section of

Startup Procedure and

Adjustment.

In general lower heating speeds will: reduce electrical con-

sumption, lower operating sound levels of the blower, and

increase the outlet air temperature delivered to the home.

The speeds available allow the blower performance to be op-

timized for the particular homeowner’s needs.

B

LOWER

H

EAT

O

FF

D

ELAY

T

IMINGS

The delay is factory shipped at 150 seconds but may be

changed to suit the installation requirements and/or ho-

meowner preference.

N

ORMAL

S

EQUENCE

OF

O

PERATION

P

OWER

U

P

The normal power up sequence is as follows:

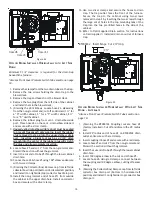

•

115 VAC power applied to furnace.

•

Integrated control module performs internal

checks.

•

LED will flash once at power up then remain on.

•

Integrated control module monitors safety circuits

continuously.

•

Furnace awaits call from thermostat.

H

EATING

M

ODE

The normal operational sequence in heating mode is as fol-

lows:

•

R and W thermostat contacts close, initiating a

call for heat.

•

Integrated control module performs safety circuit

checks.

•

Induced draft blower is energized for a 15-second

prepurge.

•

Igniter warm up begins upon presence of closed

pressure switch contacts.

•

Gas valve opens at end of igniter warm up period,

delivering gas to burners and establishing flame.

•

Integrated control module monitors flame presence.

Gas valve will remain open only if flame is detected.

•

Circulator blower is energized on heat speed following

a thirty (30) second blower on delay.

•

Furnace runs, integrated control module monitors

safety circuits continuously.

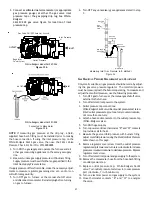

•

R and W thermostat contacts open, completing the

call for heat.

•

Gas valve closes, extinguishing flame.

•

Induced draft blower is de-energized following a

fifteen second post purge.

•

Furnace awaits next call from thermostat.

C

OOLING

M

ODE

The normal operational sequence in cooling mode is as fol-

lows:

•

R,Y, G thermostat thermostat contacts close,

initiating a call for cool.

•

Integrated control module performs safety circuit

checks.

•

Outdoor fan and compressor are energized.

•

Circulator blower is energized on the cool speed.

•

Furnace circulator blower and outdoor cooling unit

run their appropriate speeds, integrated control

module monitors safety circuits continuously.

•

R,Y, G thermostat contacts open, completing the

call for cool.

•

Outdoor fan and compressor are de-energized.

•

Circulator blower continues running during a cool

off delay period of 45 seconds.

•

Furnace awaits next call from thermostat.

F

AN

O

NLY

M

ODE

The normal operational sequence in fan only mode is as fol-

lows:

•

R and G thermostat contacts close, initiating a

call for fan.

•

Integrated control module performs safety circuit

checks.

•

Circulator blower is energized on heat speed.

•

Circulator blower runs, integrated control module

monitors safety circuits continuously.

•

R and G thermostat contacts open, completing

the call for fan.

•

Circulator blower is de-energized.

•

Furnace awaits next call from thermostat.

Содержание DM96SE

Страница 37: ...37 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 38: ...38 THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 39: ...39 THIS PAGE LEFT INTENTIONALLY BLANK ...