EN

20

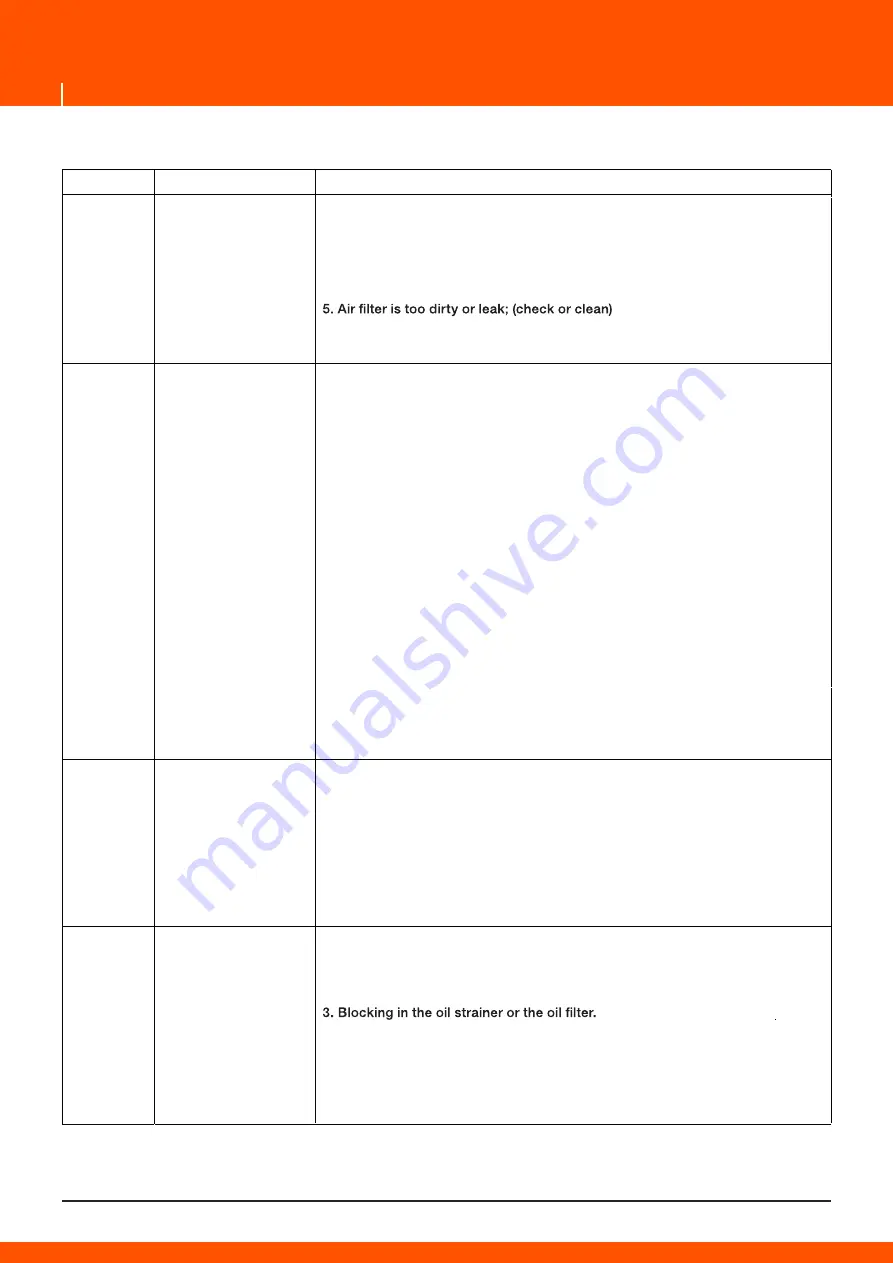

Fault judge and eliminate

Fault

Number

1. Safety slice was burnt out; (replace)

2. GND can not connect well; (settle)

3. Pressure reducer water cycle emerges ice block.

(Handling method: Clear the water cycle)

4. Pressure reducer low-pressure chamber leaks or diaphragm broken,

repair or replace (settle or replace)

6. Solenoid valve fault closed.

7. Fault of emergency stop switch.

Sudden Stop

1. Ignition time is too early which causes detonation.

2. Ignition time is too late which causes exhaust pipe blasting or mixer

tempering.

Dealing methods for Item 1 and 2: adjust the ignition time of the distributor

3. Gap between the piston and cylinder is too much, it knocks when start

the engine, and lighten as heat of the engine.

4. The gap between piston pin and pin hole is too big, sound is light but tine,

especially clearer when idling.

5. The gap between main bearing and connecting rod bearing is too big,

can hear the spare parts knocks when the engine speed lower down, it

sounds heavy and strong.

6. The crankshaft end play is too big, can hear the crashes when idling.

7. Valve spring break off, valve clearance excessive gap, that can hear the

litter sound or rhythm knocking around the cylinder cap.

Dealing methods for Item 3, 4, 5, 6 and 7: replace the parts, insure the

regulation gap.

8. When the piston hits the cylinder, that can hear the knocks of metal

crashes around the cylinder cap.

Eliminate method: check the piston and valve to see whether they are hits or

not, then check distribution gear mark.

9. When the speed lower down because of too large of abrade gear gap,

that can hear the knocks in the gear room.

Dealing methods for Item 8 and 9: replace the gear.

Abnormal sound

when the engine is

operating.

6

1. Check around to see whether it is vantilate or not.

2. Too much of the engine load.

3. Engine oil is not enough or too much.

4. Down exhaust is too much.

Dealing methods for Item 4: replace the packing ring or the cylinder liner

5. Blocking in the oil cooler, oil temperature controller valve opened, the

temperature is not right, Shell is blocked by the dirt.

6. Oil mark is not correct (oil viscosity is too high).

Temperature of the

engine oil is too high.

7

1. Not enough oil in the oil pan.

Dealing method: add oil to the selected level.

2. Damage of oil pump gear.

Dealing method: replace the oil pump.

4. Damage or blocking in the relief valve or the pressure stablizer spring.

5. Blocking or leakage in the oil pipe.

Dealing methods for Item 3, 4 and 5: replace the spare parts.

Pressure of engine oil

is not enough.

8

5

Содержание DAPD17REQ-EC

Страница 26: ...2...

Страница 29: ...EN 5 2 1 2 3 4 5 3 DAPD17REQEC 1...

Страница 41: ...17 OFF ATS...

Страница 42: ...18 E N LPG NG...

Страница 43: ...19 2 1 2 3 4 LPG NG 5 6 LPG 3 1 2 3 4 5 4 1 2 3 FBT 4 5 3 4 5 1 2 XKO GEAR 6 7 8 9 10 11 12 13 14 15 16...

Страница 44: ...20 EN 5 1 2 GND 3 4 5 6 7 6 1 2 1 2 3 4 5 6 7 8 3 4 5 6 7 9 10 8 9 7 1 2 3 4 5 4 6 8 1 2 3 4 5 6 3 4 5...

Страница 45: ...21 9 1 2 3 10 1 2 3 4 11 1 2 3 4 5 6 7 4 5 6 12 1 2 3 13 1 2 14 1 2 3 15 1 2 3...

Страница 46: ...22 EN AC AVR...

Страница 47: ...23 3 5...

Страница 48: ...24 EN 1 2 1 2 12 DC 1 12 70 2 20 DC 200 DC 3 90 1...

Страница 49: ......

Страница 50: ...www daewoopowerproducts com Manufactured under license of Daewoo International Corporation Korea...