66

Culligan® Series M2 Reverse Osmosis

66

Cat. No. 01023095

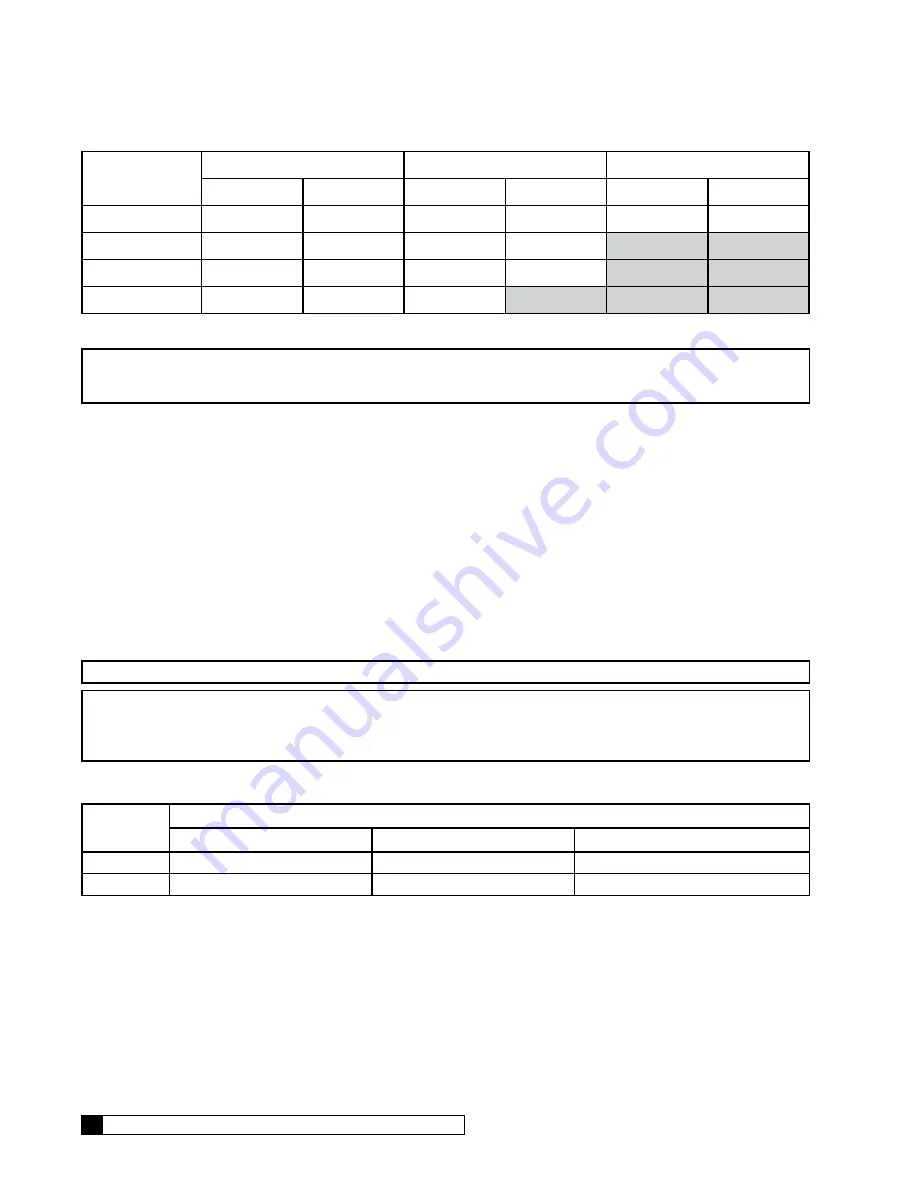

Test Data

Feed

Product

Concentrate

New

Now

New

Now

New

Now

Flow (gpm)

TDS (ppm)

Pressure (psi)

Temp. (°F)

Table 7. System performance—new vs. present.

NOTICE

If new data is not available, use the specifications listed earlier in these instructions. However,

keep in mind that the new elements may have exceeded these specifications, so performance may

have decreased even if the unit still exceeds specifications.

In addition to differences in product flow and quality (TDS), determine whether there were any changes in concentrate wa-

ter flow, feed water TDS, feed water temperature and feed or product pressures. Changes in these values provide clues

to indicate the cause of any problems with the product water.

If there were changes in feed water temperature or pressure, the product water flow rates will have to be converted to flow

rates under standard conditions (77° F and 200 psig) in order for any comparison to be valid. Refer to the Product Flow

Calculation section to calculate flow rates under standard conditions, then compare the converted values. A decrease in

the product water flow may have been due only to a decrease in temperature or pressure, in which case cleaning would

not be indicated.

If any change in the performance of the elements was not due to a change in operating conditions, it may be time to clean

the elements. In general clean the elements:

1. When the product flow rate decreases by 10% (or when the feed pressure must be increased by 10% to main-

tain the same product flow), or

2. When the percent of rejection decreases below specification.

NOTICE

Replace the prefilter cartridges if they are discolored by iron.

NOTICE

Because strong chemicals are used to clean the elements, maintenance cleaning is not recom-

mended. If the elements need to be cleaned frequently (more than twice a year), the pretreatment

may be inadequate. Obtain a current water analysis and test the Silt Density Index and the Total

Chlorine level of the water on-site to review what changes in pretreatment may be needed.

When cleaning is required, the type of material which is fouling the element should be identified, if possible. Refer to

Table 8 to determine the possible causes of the performance change.

Percent

Rejection

Flow

Low

Normal

High

Low

Hardness Scale

Hardness Scale (light) or Iron

Membrane Damage

High

Silt or Biofouling

—

Membrane Damage (light)

Table 8. Performance change possible causes.

For example, if the product flow is low but the percent rejection is normal, the likely causes of the problem are silt or

biofouling. Please note that if the product flow rate has increased (with no increase in temperature or pressure) the likely

reason is damage to the membrane, which cannot be repaired by cleaning.