OWNERS MANUAL | Cobolt Skyra™ |

D0423-E JANUARY 2018

33 | 45

Settings Optimization in modulation mode

Cobolt Monitor™ software allows the user to optimize the laser performance while in modulation mode. During

manufacturing the DPL settings are in digital modulation at 1 kHz and a 50% duty cycle. When modulating with a

different input signal the user can expect changes in the pulse shape, peak power and average power. TEC 3, High

current and Low current can be adjusted to re-optimize performance, though 100 % of the performance may not be

recoverable.

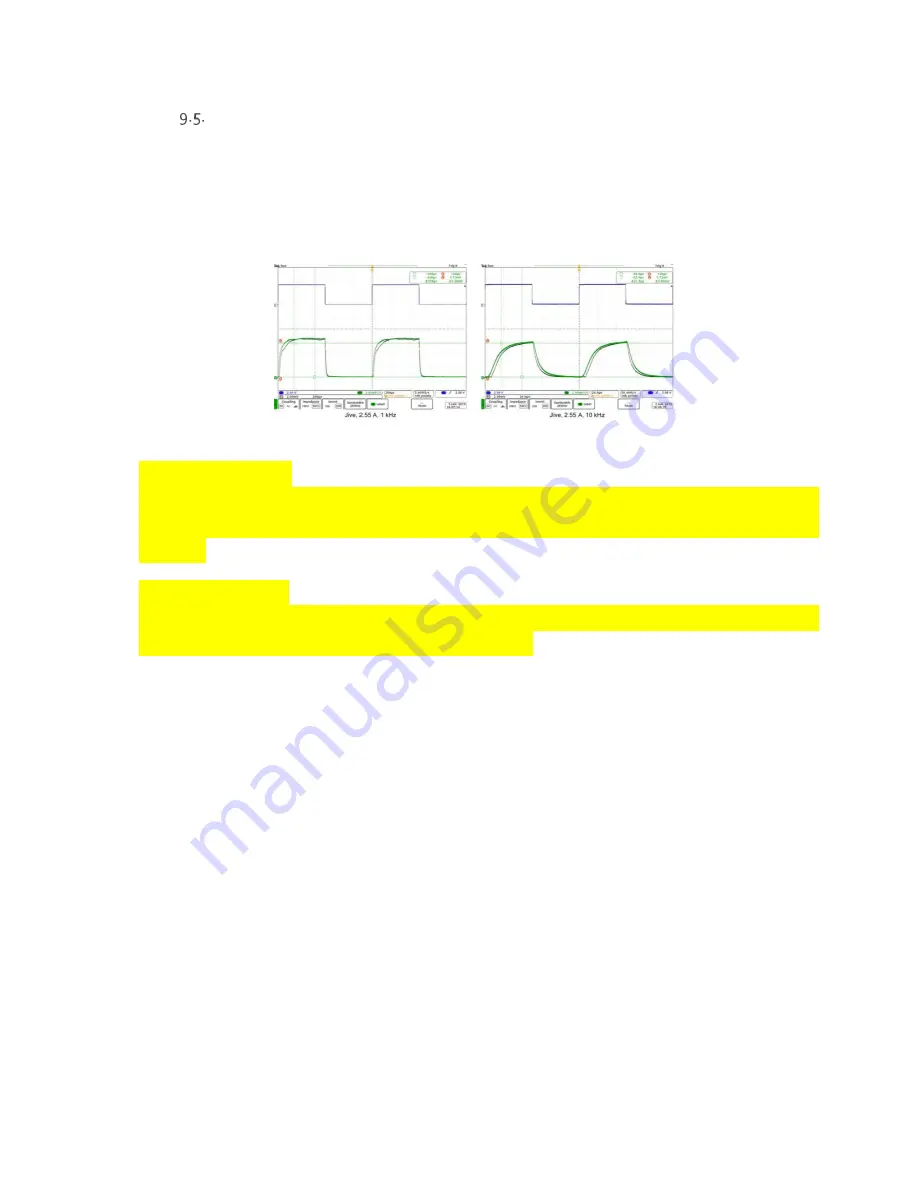

An example of the effect of modulation frequency on pulse shape at 1 kHz versus 10 kHz

High Current Adjustment

It is not always sufficient to increase the TEC 3 temperature to achieve maximum average power. When necessary the

High current level can be increased up to as much as 3000 mA, the maximum safe operating current for DPL as set at

the factory.

Low Current Adjustment

If the application requires, it is possible to set the low current to

0

mA where a perfect dark state is required, but

adjusting the lower current can have adverse effects on pulse shape.

TEC 3 Adjustment

The DPL’s optical output power is influenced heavily by the match between the pump diode’s emission spectrum and

the laser crystal’s gain spectrum. Modulation mode operation is achieved by direct modulation of the drive current to

the pump diode. Decreasing the ON time and thereby the diode temperature, must be compensated by an increase in

the platform temperature to maintain a constant pump diode wavelength. TEC 3 is used to control the platform

temperature when in modulation mode and can be used to optimize the temperature of the pump diode. Adjust the

TEC3 temperature inversely with duty cycle.