5

show the top-level display, press the ESC key until a blank dis

-

play is shown. Then use the

and

keys to scroll through

the top level categories.These are listed in Appendix A and will

be indicated on the Navigator by the LED next to each mode list

-

ed on the face of the display.

When a specific mode or sub-mode is located, push the

ENTER key to enter the mode. Depending on the mode, there

may be additional tiers. Continue to use

and

keys and

the ENTER key until the desired display item is found. At any

time, the user can move back a mode level by pressing the ESC

key.

Items in the Configuration and Service Test modes are pass

-

word protected. The display will prompt for a PASSWORD.

Use the ENTER and arrow keys to enter the 4 digits of the

password. The default password is 1111.

Pressing the ESC and ENTER keys simultaneously will dis

-

play an expanded text description for each display point.

Changing item values or testing outputs is accomplished in the

same manner. Locate and display the desired item. If the dis

-

play is in rotating auto-view, press the ENTER key to stop the

display at the desired item. Press the ENTER key again so that

the item value flashes. Use the arrow keys to change the value

or state of an item and press the ENTER key to accept it. Press

the ESC key and the item, value, or units display will resume.

Repeat the process as required for other items.

If the user needs to force a variable, follow the same process as

when editing a configuration parameter. When using the Navi

-

gator display, a forced variable will be displayed with a blink

-

ing “f” following its value. For example, if supply fan request

-

ed (

FAN.F

) is forced, the display shows “YESf”, where the “f”

is blinking to signify a force on the point. Remove the force by

selecting the point that is forced with the ENTER key and then

pressing both arrow keys simultaneously.

Depending on the unit model, factory-installed options, and

field-installed accessories, some of the items in the various

mode categories may not apply.

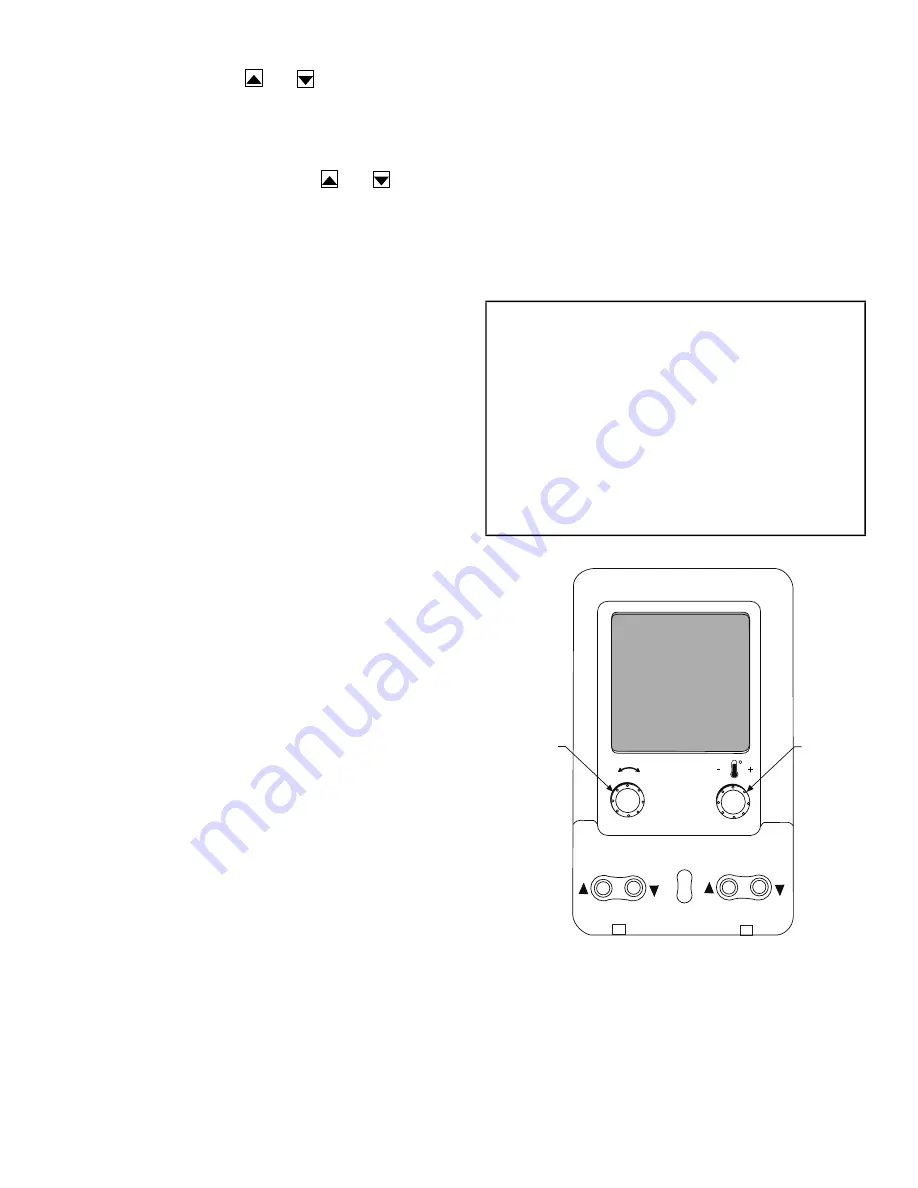

System Pilot™ Interface

The System Pilot interface (33PILOT-01) is a component of

the Carrier 3V™ system and can serve as a CCN user-interface

and configuration tool.

Additionally, the System Pilot interface can serve as a wall-

mounted temperature sensor for space temperature measure

-

ment. The occupant can use the System Pilot interface to

change set points. A security feature is provided to limit access

of features for unauthorized users. See Fig. 2 for System Pilot

interface details.

CCN Tables and Display

In addition to the Navigator display, the user can also access

the same information through the CCN tables by using the Sys

-

tem Pilot, Service Tool, or other CCN programs. Details on the

CCN tables are summarized in Appendix B. The point names

displayed in the CCN tables and the corresponding local dis

-

play acronyms available via the Navigator display may be dif

-

ferent and more items are displayed in the CCN tables. As a

reference, the CCN point names are included in the local dis

-

play menus shown in Appendix A.

GENERIC STATUS DISPLAY TABLE

The GENERIC points table allows the service/installer the ability

to create a custom table in which up to 20 points from the 5 CCN

categories (Status, Config/Service-Config, Set Point, Mainte

-

nance, and Occupancy) may be collected and displayed.

In the Service-Config table section, there is a table named “ge

-

nerics.” This table contains placeholders for up to 20 CCN

point names and allows the user to decide which points are dis

-

played in the GENERIC points table. Each one of these place-

holders allows the input of an 8-character ASCII string.

Using a CCN method of interface, go into the Edit mode for

the Service-Config table “generics” and enter the CCN name

for each point to be displayed in the custom points table in the

order they will be displayed. When done entering point names,

download the table to the rooftop unit control.

Fig. 2 —

System Pilot User Interface

IMPORTANT: The computer system software (Comfort

-

VIEW™, Service Tool, etc.) that is used to interact with

CCN controls always saves a template of items it considers

as static (e.g., limits, units, forcibility, 24-character text

strings, and point names) after the software uploads the ta

-

bles from a control. Thereafter, the software is only con

-

cerned with run time data like value and hardware/force sta

-

tus. With this in mind, it is important that anytime a change

is made to the Service-Config table “generics” (which in

turn changes the points contained in the GENERIC point ta

-

ble), a complete new upload is performed.

This requires

that any previous table database be completely removed

first.

Failure to do this will not allow the user to display the

new points that have been created and the software will

have a different table database than the unit control.

S

CROLL

+

-

NAVIGATE/

EXIT

MODIFY/

S

ELECT

PAGE

Содержание WeatherExpert 48N2

Страница 135: ...135 Fig 18 48 50N Typical Power Schematic Nominal 075 Ton Unit Shown ...

Страница 136: ...136 Fig 19 48 50N Typical Power Schematic Nominal Ton 90 150 Units Shown ...

Страница 137: ...137 Fig 20 48 50N Main Base Board Input Output Connections ...

Страница 138: ...138 Fig 21 48 50N RXB EXB CEM Input Output Connections a48 9307 ...

Страница 139: ...139 Fig 22 48 50N EXV SCB Input Output Connections a48 9308 ...

Страница 140: ...140 Fig 23 48N Typical Modulating Gas Heat Unit Control Wiring ...

Страница 141: ...141 Fig 24 50N Typical Electric Heat Unit Control Wiring ...

Страница 144: ...144 Fig 27 48N Typical Gas Heat Section Wiring Nominal Ton 120 to 150 Units ...

Страница 145: ...145 Fig 28 48 50N Typical Power Component Control Wiring 460 v ...

Страница 146: ...146 Fig 29 48 50N Component Control Wiring 575 v Nominal Ton 075 to 150 Units ...

Страница 147: ...147 Fig 30 48 50N Component Arrangement Power Box ...

Страница 148: ...148 Fig 31 48 50N Component Arrangement Control Box ...

Страница 168: ...168 Fig 47 Sensor and Ignition Position Fig 48 Combustion Blower Details SENSOR DETAILS IGNITION DETAILS ...

Страница 240: ...240 APPENDIX D VFD INFORMATION CONT Fig G VFD Bypass Wiring Diagram WHEN USED ...