68

COMPLETING THE INSTALLATION

This section provides instructions on how to perform a final

check of the installation. Do not energize the VFD circuit

breaker. This should only be done by qualified Carrier person-

nel in accordance with the 23XRV Start-Up and Service

Manual.

Checking the Installation —

Use the following pro-

cedure to verify the condition of the installation:

1. Turn off, lock out, and tag the input power to the drive.

Wait five minutes.

2. Verify that there is no voltage at the input terminals (L1,

L2, and L3) of the power module.

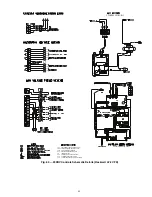

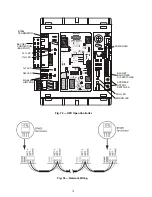

3. a. For LF-2 VFD, verify that the status LEDs on the

DPI communications interface board are not lit.

See Fig. 68. The location of the communications

interface board is shown in Fig. 10.

b. For Std Tier VFD, verify that the keypad and drive

status indicators (Fig. 69) are not lit. The location of

the drive status indicator is shown in Fig. 11.

4. Remove any debris, such as metal shavings, from the

enclosure.

5. Check that there is adequate clearance around the

machine in accordance with the certified print.

6. Verify that the wiring to the terminal strip and the AC

input power terminals is correct.

7. Check that the wire size is within terminal specifications

and that the wires are tightened properly.

8. Check that specified branch circuit protection is installed

and correctly rated.

9. Check that the incoming power is rated correctly.

10. Verify that a properly sized ground wire is installed and a

suitable earth ground is used. Check for and eliminate any

grounds between the power leads. Verify that all ground

leads are unbroken.

Oil Pump and Oil Heater —

The oil pump and oil

heater are wired at the factory. It is not necessary to connect

additional wiring to these components. See Fig. 72-74.

Connect Control Wiring —

All control wiring must

use shielded cable. Refer to the job wiring diagrams for cable

type and cable number. Make sure the control circuit is ground-

ed in accordance with applicable electrical codes and instruc-

tions on machine control wiring label.

Carrier Comfort Network

®

Interface —

The Car-

rier Comfort Network (CCN) communication bus wiring is

supplied and installed by the electrical contractor. It consists of

shielded, 3-conductor cable with drain wire.

The system elements are connected to the communication

bus in a daisy chain arrangement. The positive pin of each

system element communication connector must be wired to the

positive pins of the system element on either side of it. The

negative pins must be wired to the negative pins. The signal

ground pins must be wired to the signal ground pins. See

Fig. 70 for location of the CCN network connections on the

terminal strip labelled CCN.

NOTE: Conductors and drain wire must be 20 AWG (Ameri-

can Wire Gage) minimum stranded, tinned copper. Individual

conductors must be insulated with PVC, PVC/nylon, vinyl,

Teflon*, or polyethylene. An aluminum/polyester 100% foil

shield and an outer jacket of PVC, PVC/nylon, chrome vinyl,

or Teflon with a minimum operating temperature range of –4 F

to 140 F (–20 C to 60 C) is required. See Table 22 for cables

that meet the requirements.

WARNING

DC bus capacitors in the VFD retain hazardous voltages

after input power has been disconnected. After disconnect-

ing input power, wait 5 minutes for the DC bus capacitors

to discharge then check both the VFD DPI communica-

tions interface board status LEDs and the VFD with a volt-

meter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to

observe this precaution could result in severe bodily injury

or loss of life.

WARNING

Voltage to terminals T1 and T3 on the 1C and 6C contac-

tors comes from a control transformer in the starter built to

Carrier specifications. Do not connect an outside source of

control power to the chiller (terminals T1 and T3). An

outside power source will produce dangerous voltage at the

line side of the starter, because supplying voltage at the

transformer secondary terminals produces input level

voltage at the transformer primary terminals (see Fig. 63,

LEGEND

Factory Wiring

Power Panel Component Terminal

Contactor

a23-1595

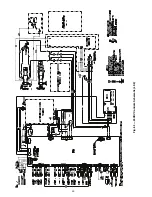

Fig. 72 — Oil Pump Wiring

Fig. 73 — Oil Heater and Control Power Wiring

LEGEND

Factory Wiring

Power Panel Component Terminal

a23-1596

Fig. 74 — Oil Heater and Control Power Wiring,

Dual-Stage Oil Heater

*Registered trademark of DuPont.

Содержание EVERGREEN 23XRV

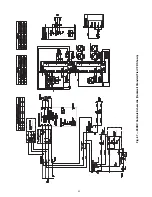

Страница 53: ...53 Fig 60 Typical Field Wiring Schematic LF 2 VFD Shown NOTE See Notes for Fig 60 on page 56 ...

Страница 54: ...54 Fig 60 Typical Field Wiring Schematic LF 2 VFD Shown cont a23 1585 ...

Страница 55: ...55 Fig 60 Typical Field Wiring Schematic LF 2 VFD Shown cont a23 1586 ...

Страница 60: ...60 Fig 63 23XRV Controls Schematic LF 2 ...

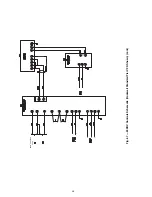

Страница 63: ...63 SEE NEXT PAGE SEE NEXT PAGE SEE NEXT PAGE Fig 67 23XRV Controls Schematic Rockwell Standard Tier VFD Shown ...

Страница 64: ...64 FROM PREVIOUS PAGE Fig 67 23XRV Controls Schematic Rockwell Standard Tier VFD Shown cont ...

Страница 73: ...73 Fig 78 Lead Lag Control Wiring Parallel Flow Application Unit with R Compressor Shown a23 1597 ...

Страница 74: ...74 Fig 79 Lead Lag Control Wiring Series Flow Application Unit with R Compressor Shown a23 1598 ...