MN702GE 060320

– 9 –

2. Pre-fire inspection • preparation

(continued)

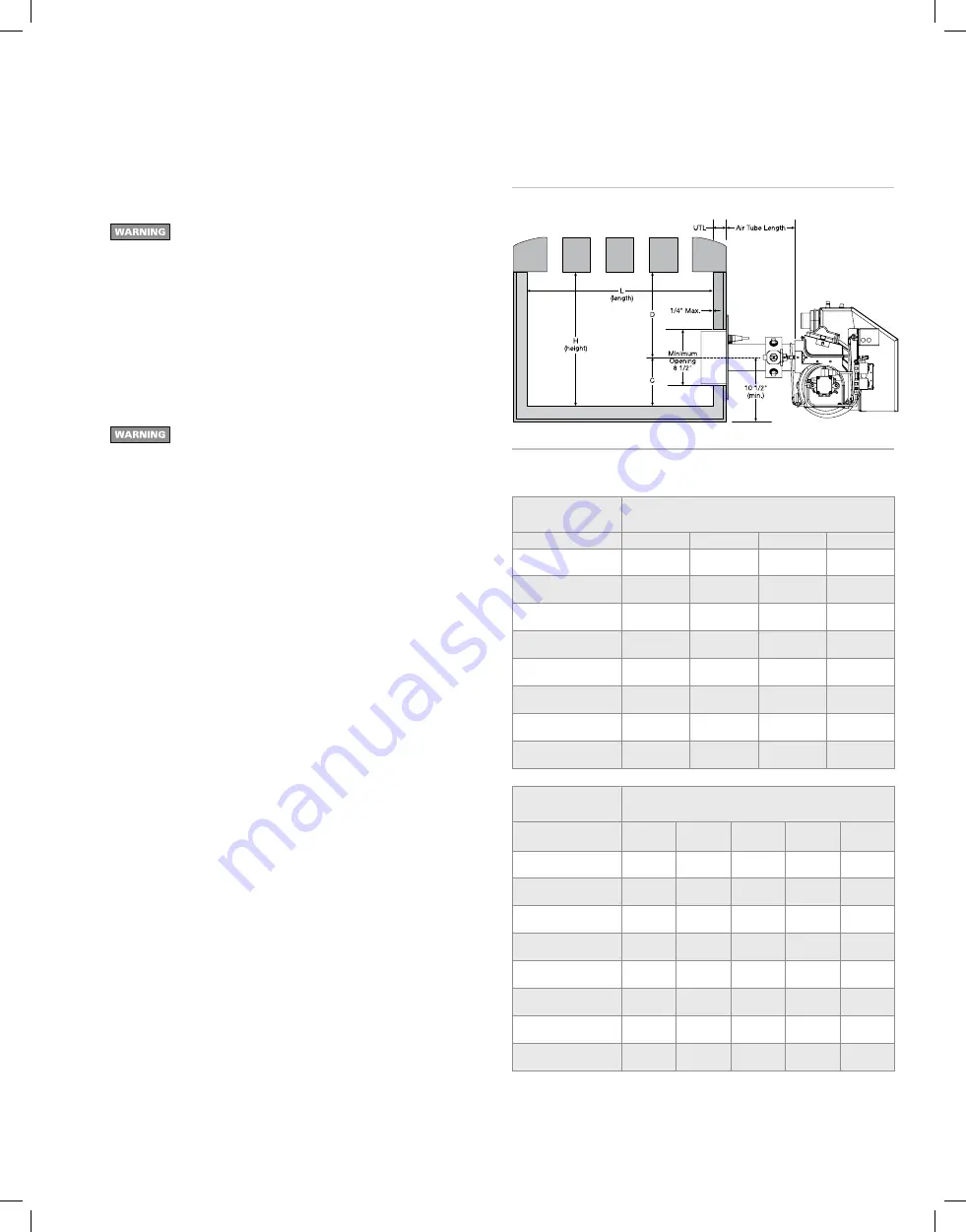

Figure 3

Chamber dimensions & tube configurations

Table 2

Minimum combustion chamber dimensions

(see Figure 3)

Prepare burner and components

Do not install or operate the burner if any component is dam-

aged or if burner does not comply with the specifications of

Table 2 and other guidelines in this manual.

Combustion chamber minimum dimensions

1.

For applications that have not been specifically tested (OEM applications),

verify that the combustion chamber provides the minimum dimensions

shown in Table 2 and Figure 3. For specific OEM applications, the

appliance testing ensures suitability of the chamber.

2.

Chamber dimensions may be larger than listed in Table 2, but should

not be excessively large.

Combustion chambers should be sized as recommended in

Table 2. They should be constructed of refractory materials

with the capacity to withstand 2600°F or higher.

It is difficult to include all possible chamber constructions in this

manual. Therefore, you should use the information presented

in this manual combined with commonly practiced techniques

when determining chamber design. If certain conditions are in

question, consult the factory.

Using chamber linings

1.

When using refractory liners or lightweight chambers, use insulating-

type refractory rated 2600°F minimum, or as specified by the appliance

manufacturer.

2.

You must install a target wall liner if flame length is close to the length

of the chamber.

3.

Use a floor liner when possible. The floor liner will improve firing in most

applications. Extend floor liner 3 to 4 inches up the side walls.

4.

Target wall liners — Extend target wall liners at least 3 to 4 inches above

the center of the flame corbel the top 1½ to 2½ inches deep.

5.

Use preformed chamber liners when available. Lining the floor and tar-

get wall water-backed combustion chambers with lightweight insulating

refractory will accomplish the same.

6.

When converting coal-fired units, install a combustion chamber in the

ashpit area, or fill the ashpit with sand up to 2 inches above the “mud

ring” of the boiler (firing through the door). Install a lightweight refractory

liner on the target wall.

Air tube insertion length (UTL)

1.

Usable air tube length (UTL) is the distance from mounting flange to end

of air tube. Verify that the end of the air tube will be flush with, or no more

than 1/4 inch short of, the inside of the appliance combustion chamber

front wall when the burner is mounted. See Figure 3 for further information.

NOTE: A flange spacer is available for appliances with less than 4" UTL.

High fire input

Refactory combustion chamber applications

(all dimensions in inches)

Gas–MBH

“L”

“W”

“C”

“H”

840

21

15.0

7.5

15

910

23

15.5

8.0

16

966

25

16.0

8.0

16

1092

28

17.0

8.5

17

1218

31

17.5

9.0

18

1330

34

18.0

9.0

18

1456

38

19.0

9.5

19

1568

43

20.0

10.0

20

High fire input

Refactory combustion chamber applications

(all dimensions in inches)

Gas–MBH

“L”

W/ target

“L”

No target

“W”

“C”

“D”

840

21

25

17.0

8.5

10.5

910

23

27

17.5

9.0

11.0

966

25

29

18.0

9.0

11.0

1092

28

32

19.0

9.5

11.5

1218

31

35

19.5

10.0

12.0

1330

34

38

20.0

10.0

12.0

1456

38

42

21.0

10.5

12.5

1568

43

47

22.0

11.0

13.0