MN702GE 060320

– 13 –

3. Install gas piping

Connect from the gas supply to the burner gas train

inlet using new, clean black iron pipe and malleable

iron fittings only. Do not use copper, brass, cast iron

or galvanized pipe or fittings.

Provide support for gas piping. Do not rest the weight

of the gas piping on burner gas train.

Provide a support for the burner gas train.

Apply pipe dope sparingly at all joints. Use only pipe

dope listed for use with propane gas. Do not use pipe

sealing tape.

Do not hold the gas valve with pipe wrench. Use

crescent wrench or other smooth-jawed device. Do

not overtighten.

Failure to comply with above could result in severe

personal injury, death or substantial property damage.

Do not expose the gas train to gas pressure in

excess of 14 inches water column. Higher pressure

could damage the valve seat, resulting in potentially

hazardous condition. When pressure testing piping

at higher pressures, disconnect burner from gas line

before testing.

If the gas supply pressure can exceed 14 inches water

column at any time, you must install a lockup type gas

pressure regulator in the gas supply piping, ahead of

the main manual gas valve installed at the burner.

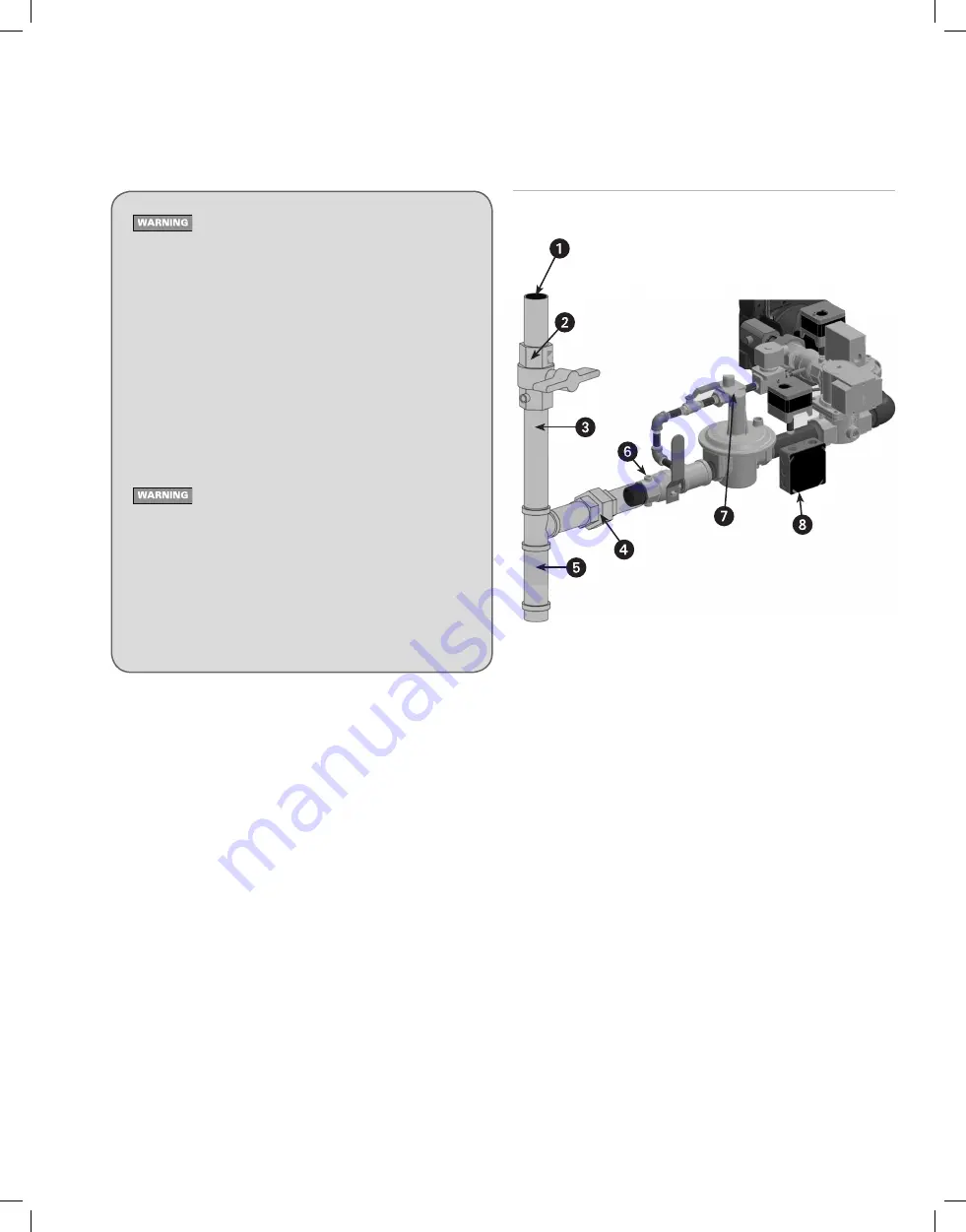

Figure 5A

Connecting gas supply piping to burner

(shown with angled gas train)

Piping from gas meter to burner

1. Verify the gas train on the burner is correctly sized. The gas train pres¬sure

drop must not be more than the gas pressure at the burner gas train en-

trance minus 3.4" w.c. (pressure required at entrance to butterfly valve).

See Figure 6 for gas train pressure drop information. The standard gas

train is 1 inch.

2. If possible, install a new gas line directly from the gas meter. If you are

using an existing gas line, verify it is clean and in good condition, and

verify it is large enough to handle the load of all connected appliances.

3. When branching from a common gas line, do not tap off from the bottom

of horizontal sections – only from the side or top.

4. Install a main manual shutoff valve, sediment trap and ground joint union

near the burner gas train connection as shown in Figure 5A.

5. If the burner is installed inside an appliance jacket, install the main manual

gas valve and sediment trap external to the jacket.

6. Size piping (or verify size) using Table 3. You will find additional informa-

tion on gas line sizing in the National Fuel Gas Code, ANSI Z223.1.

Gas supply pressure – natural gas or propane Maximum supply pressure:

14 inches w.c.

Minimum supply pressure: 5 inches w.c.

Test and purge gas line

Read WARNING above.

Pressure test and purge the line. Pressure testing should be done by the gas

supplier or utility, following all applicable codes.

1 Pipe to meter or branch

2 T-handle main manual gas valve

3 Use clean, burr-free black iron

pipe and malleable iron fittings

4 Ground joint union

5 Sediment leg

6 Pressure tap, 1/4" (upstream

shown, outlet not shown)

7 Gas regulator access screw

(the regulator spring is located

under the adjusting screw)

8 Gas train wire junction box