(3) LF / Eject correction

After replacement of the feed roller, platen unit, LF / Eject encoder, encoder film, or logic board in repair servicing or in

refurbishment operation, perform the adjustment to maintain the optimal print image quality.

If the print quality is considered unaffected by replacement of those parts, it is not necessary to perform LF / Eject correction.

1) Print the LF / Eject correction pattern.

Click

LF/EJECT

of the Service Tool on the connected computer, select the paper source and the paper type, and print the

pattern. 5 sheets of paper will be used for the pattern printing.

- Paper source: Select either

Rear tray

or

Cassette

.

- Media type: Select one from

HR-101

,

GF-500/Office Planner

,

HP Bright White

, and

Canon

Extra/STEINBEIS

.

2) When printing is finished, the machine returns to be ready for selection of another function ("Service Mode Idle" is displayed

on the LCD).

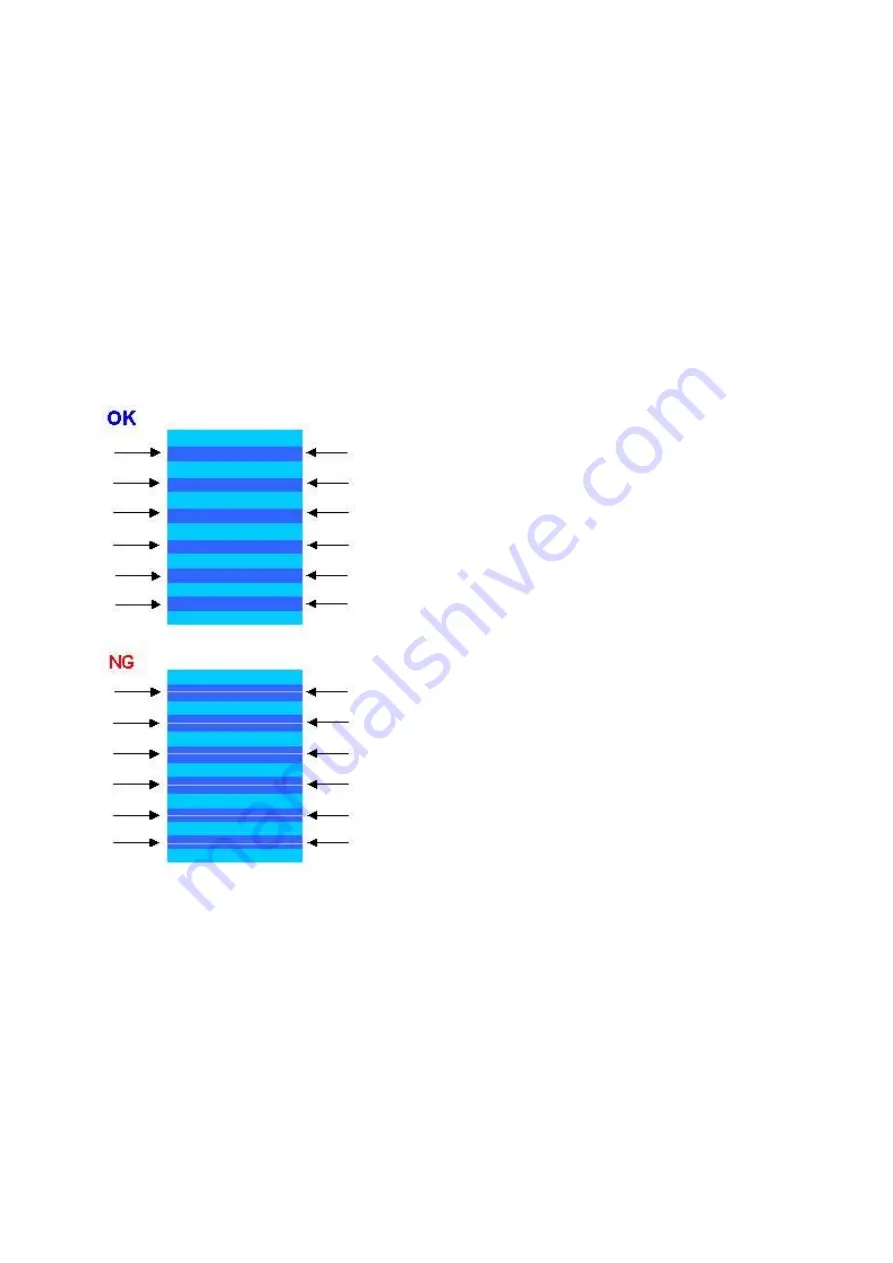

3) In the printout, determine the Pattern No. in which streaks or lines are the least noticeable for the LF check pattern and the Eject

check pattern respectively.

(LF Pattern No. 0 to 4, Eject Pattern No. 0 to 4)

4) Select and set the correction values.

In the

LF/EJECT Correction

section of the Service Tool, select the Pattern No. (from 0 to 4) determined in step 3) for

LF

and

EJECT

respectively, and click

Set

.

5) The selected LF and Eject correction values are written to the EEPROM, making the E-MIP correction value (which was set at

shipment from the production site) invalid.

Note: At the production site, the E-MIP correction, which is equivalent to the LF / Eject correction, is

performed using the special tool, and the E-MIP correction value is written to the EEPROM as the valid

data.

When LF / Eject correction is performed, the LF / Eject correction values become valid instead of the E-

MIP correction value (thus, in the initial EEPROM information print, "LF = *" and "EJ = *" are printed,

but the selected values are printed after the LF / Eject correction).

49 / 63

Содержание PIXMA MX870 Series

Страница 8: ...5 63 ...

Страница 9: ...6 63 ...

Страница 31: ...8 Remove the main case no screws 28 63 ...

Страница 34: ...31 63 ...

Страница 35: ...4 Remove the LCD ass y no screws 5 Remove the panel board 11 screws 32 63 ...

Страница 39: ...2 Remove the PE sensor board 5 screws 36 63 ...

Страница 64: ... 2 Service test print Service test print sample unified inspection pattern print 61 63 ...

Страница 65: ... 3 Ink absorber counter value print Print sample 4 6 Verification After Repair 62 63 ...